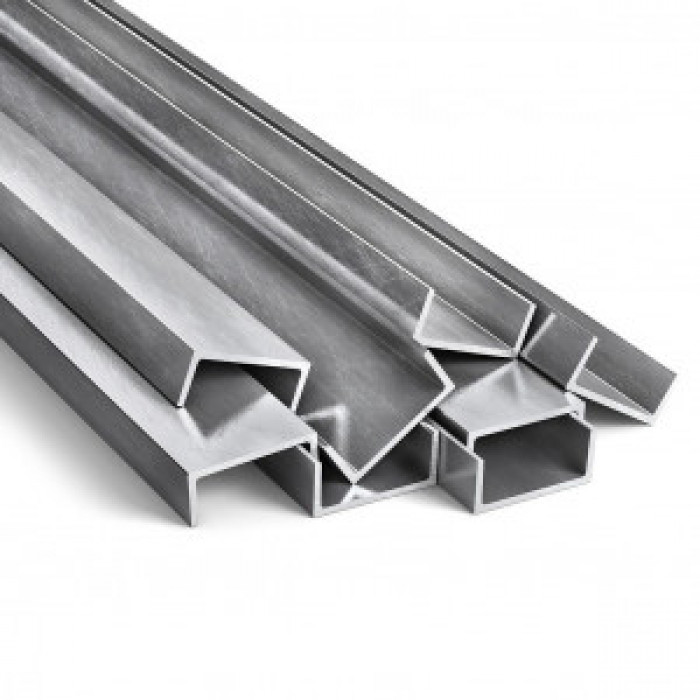

Steel Channel bent 32х32х2 st1-3ps / sp L = 12000mm - shaped metal rolling which cross section has the letter "P". The axial center of symmetry passes through the central wall, due to which the profile with this shape has a high load-bearing capacity, resists deformation under the influence of dynamic and static moments and allows to predict the stress-strain state of structural elements at a high level. Certain types of channels are perfectly amenable to welding and machining.

The Steel Channel bent is applied by the municipal enterprises. It is actively used at the organization of various installation and repair works and at laying of ground communications, creation of designs for load-lifting mechanisms and road bumpers. But the greatest application of the channel steel hot-rolled and bent types are widely acquired in the construction industry, where they are used as a load-bearing and structural element: when pouring foundations; at construction of walls, flat and arched overlappings; in the construction of bridge beams, industrial sites, bridges and overpasses.

This type of channel is manufactured in accordance with GOST. It is divided into two types, each corresponds to a certain GOST: an equal-shelf bent channel, the production of which is regulated by GOST 8278 and an unequal bent channel - GOST 8281. In the general case, the manufacture of bent steel profiles should be carried out taking into account GOST 11475.

The production of a bent channel takes place on special roll-forming machines, using various types of steel, including:

Production of bent steel channel

Rolled hot rolled - hot rolling technology involves changing the crystal lattice of steel;

Rolled cold-rolled - this method of production allows you to create products that have increased resistance to deformation. This technology requires work to be performed at a relatively low temperature, so the crystal lattice of steel does not change;

Structural;

carbon;

Low-alloyed - with the addition of special alloying additives that increase the operational characteristics of rolled metal products.

The main characteristics of the bent steel channel:

Ability to carry large axial loads;

Can be used without welding;

Ability to withstand bending loads;

Light weight;

The product is excellent for welding.

All bent steel channels are divided into three main generally accepted categories according to rolling accuracy:

high precision;

Increased accuracy;

Ordinary precision.

With regard to the shape of the structure of the steel bent profile, there are four corresponding categories:

Both shelves are parallel to each other - denoted by "P";

Light products with parallel edges of the shelves - has the designation "L";

The edges of the shelves from the inside are at an angle - "U";

Special purpose profile - "C". Technical requirements for the manufacture of a bent channel

In the production of bent profiles, only steel of certain grades is used, in accordance with GOST. According to the standards, prints, rolled-in bubbles, individual nicks can be allowed on the surface of products, but cracks, scale, shells, dirt and multiple swellings are not allowed. The edges and ends of the workpieces according to the standard 11475 do not allow nicks, delaminations or a drawn edge. In a small number of nicks and dents are acceptable if they do not take the dimensions of the product beyond the nominal. Depending on the quality group, the products may or may not have cracks according to the standard. If the profile is of poor quality, cracks up to 10 mm long are allowed at the bend for a 2 mm thick profile. If this parameter is within 2-5 mm, then the length can be already 15 mm, and for a thickness of more than 5-20 mm and above.

Rolled metal products are produced on the machine, therefore, a decrease in the quality of products is possible only if the calibration of the rolls was performed incorrectly.

Regardless of the steel used in the manufacture of profiles, products can be mounted in two ways, both by bolting and by welding.

Bent steel channel marking

Such rolled metal products are marked according to the H × W × T scheme, where:

B - height, which usually ranges between 25 and 310 mm;

W - width, which according to the standard is in the range between 26 and 100 mm;

T - thickness, fluctuates between 2 and 6 mm.

Curved unequal-shelf channel GOST 8281-80

According to this standard, a roll-formed channel is usually made from boiling carbon or semi-quiet steel, which has a tensile strength of more than 460 units. Can be used and carbon steel, low alloy steel, having the same value of tensile strength.

Limit deviations from 90 degrees depend on the width of the shelf, divided into several categories:

Up to 100mm;

Above 100mm;

High strength products.

Curved unequal-shelf channel according to GOST 8281-80 standards can be from 4 to 11.8 m.

Channel bent steel equal-shelf GOST 8278-83

This standard applies to all products obtained using roll forming tools using billets of various steels. According to the standard, maximum deviations in the production process are allowed, which relate to the height of the profile wall and the accuracy of profiling:

The wall height is less than 50mm, then the accuracy is acceptable with a deviation of 0.75mm, for increased accuracy and for normal accuracy the deviation can be - 1mm;

With a wall height of 50-100mm, deviations are allowed - 1.25; 1.3; 1.5mm for all accuracy classes;

For a height of 100-150mm, deviations are allowed for high accuracy and increased accuracy - 1.5mm, and for normal accuracy - 2mm.

According to the 8287 standard, the length of the bent profile can be selected in the range from 3 to 11.8 m. If random lengths are used, then they can be no more than 7% of the mass of the lot. It is also allowed to produce lengths that are multiples of the measured ones. The value of the maximum deviations of the length is selected depending on the length. Positive characteristics of the bent steel profile:

Lack of welding during installation work;

Smooth material surface;

From us you will be able to buy the Steel Channel bent at the most favorable price in Ukraine. The wide range and possibility of deliveries of batches of armature with measured, unmeasured length allows us to carry out any orders quickly and qualitatively, helping you to carry out any construction works in time.

No questions about this product, be the first and ask your question.