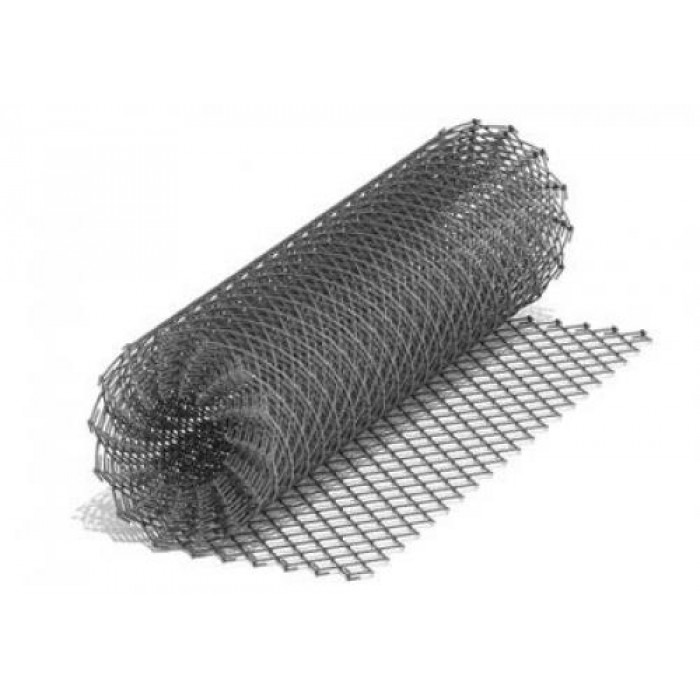

Steel mesh netting 50x50x1.8 mm, height 2m is a metal mesh woven using a special technology (a flat wire spiral is screwed into one another) using a mesh weaving machine. Named after the German Karl Rabitz, who invented and patented the netting machine at the end of the 19th century.

Scope of chain-link:

fencing of the territory (fence, gate, gate);

strengthening of land slopes, strengthening of mine workings;

production of enclosures for animals and birds;

fencing of sports complexes (for example, tennis courts);

screening of loose materials;

fastening of heat-insulating materials;

as a basis for plaster (reinforced mesh).

The size of the mesh cells of the chain-link is determined by the distance between the opposite sides of the rhombus, which is called the gap. You can buy a chain-link mesh with a mesh size of 5 to 100 mm.

It should be noted that GOST regulates the diameter of the wire from which the mesh is made with a certain cell size. For example, a mesh with a cell size of 10x10 can be made from wire with a diameter of 1.4-1.6 mm. As the lumen of the cell increases, the diameter of the wire used for its production increases.

The chain-link mesh is used for: fencing, screening sand, clay and other bulk materials, making cages, enclosures for dogs in the house and animals in the zoo, reinforcing the plaster layer, fencing rotating parts, blocking ventilation holes, wrapping poles to prevent sticking ads, making containers for storage.

The chain-link is a woven fabric with steel wire cells. Depending on the purpose, it is used for indoor and outdoor work, for the construction of fences, fences for front gardens. This is not an expensive material, widely used due to its versatility. The weight of the chain-link mesh is another plus, since additional reinforcement of the foundation for structures is not required. If you are interested in a metal mesh, the price is specified on our website.

Chain-link mesh characteristics: thickness, weight and shape

For weaving the chain-link mesh, round wire is used. It is produced in three types:

uncoated steel;

galvanized steel wire;

steel with polymer coating.

The diameter of the wire for weaving is from 1.2 to 5 mm. The larger the mesh size, the larger the wire diameter used.

The weight of the canvas depends not only on the diameter of the wire, but also on the size of the cells. The larger the cell, the less 1 square meter will weigh. So, with a wire diameter of 1.8 mm, a chain-link with 15x15 cells weighs 3.06 kg / m3, and a canvas with 35x35 mm cells weighs 1.28 kg / m3.

netting net weight photo

Also, the weight of the chain-link mesh depends on the mesh coverage; a non-galvanized mesh will be lighter than a galvanized one. The heaviest mesh is produced with a polymer coating.

Mesh chain-link characteristics of types of coverage:

not galvanized "black" wire. It rusts on contact with moisture and can be completely destroyed in 2-3 years. If it is used for fencing, then the mesh must be painted to extend the shelf life. Most often, a non-galvanized sheet is used for plastering, since after the solution has dried, the mesh does not come into contact with moisture;

galvanized wire has a special corrosion-proof zinc coating that protects against moisture. Such a coating increases the service life of the material by ten or more years. If the upper, protective layer is damaged, for example, during installation or operation, then rust may appear in these places;

with polymer coating. Unlike the previous version, here is a polymer coating that not only protects against moisture, but is also resistant to temperature extremes, does not fade in the sun and comes in different colors. This option is suitable for building envelopes.

The chain-link is produced in two versions: in the form of a sheet with a frame around the edges, in the form of a roll. The width of the chain-link mesh is 10; 15; 18 meters, roll height - 1.2 and 1.5 meters.

Areas of use

The chain-link is widely used in various fields. The most common application in construction:

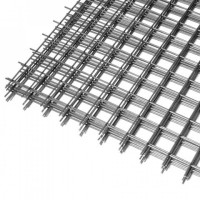

for reinforcing plaster. The most inexpensive option is used here - this is not galvanized wire. It is attached to the wall with nails or self-tapping screws and promotes adhesion of the wall material and the plaster layer. It is used in the construction of residential and public buildings. For industrial facilities, the use of chain-links for plastering allows you to avoid wall deformations with increased vibration. Reinforcement of self-leveling industrial floors is also carried out here. This allows you to move heavy objects across the floor without harm to the coating;

for reinforcing the strip foundation, a metal sheet with small and large cells is used here;

in the reconstruction of facades of buildings with architectural stucco.

Used for engineering structures:

pipes of external heating mains are reinforced with a stack with medium-sized cells. This allows the layer of heat-insulating coating not to crumble from the surface of the metaloh pipe;

to protect outdoor lighting poles. Such an event will protect the pillars from the encroachments of vandals;

to strengthen earth masses. This is necessary to prevent shedding of mountain slopes, river banks and other water bodies. It is also used in landscape design for the construction of retaining walls and the strengthening of earthen masses. This option is used to create public recreation areas, it can also be performed in private construction.

What grid for plaster is best suited? It is more economical to use a non-galvanized chain-link.

Types of mesh weaving

The metal sheet is formed from wires by weaving. Mesh chain-link types of weaving produced on modern machines:

square cells;

diamond-shaped cells, with an acute angle equal to 60 °;

square cells;

hexagon cells.

The minimum size of a square cell is 5x5 mm. This is the most durable mesh chain-link; its shape can be either square or diamond-shaped. Bird cages and animal pens are made from it. It is also used in construction and for screening bulk materials.

what grid for plaster photo

The maximum cell size is 100x100 mm. The larger the mesh size, the thicker the braiding wire used.

Benefits of chain-link mesh and service life

Mesh netting advantages:

strength, lack of shading, quick installation and relatively low weight made the chain-link a popular material for creating fences. It is used both for personal plots and for fencing sports fields. In the latter case, a polymer-coated mesh is used;

high strength of the material allows it to be used in construction;

the small weight of the mesh does not give an additional load on the foundation;

the absence of toxic emissions allows it to be used for fencing in animal husbandry and poultry farming;

quick installation possibility.

Long service life is another advantage of this material. This allows the mesh to be used for engineering structures, walls of residential and public buildings, and in industrial facilities. The service life depends on the spraying and the place of use. The service life of a galvanized mesh is more than 25 years, but if it is used for fencing near an aggressive environment, such as manure, then its service life will be significantly reduced due to nitrogen emissions. The grid the chain-link galvanized is most often used for creation of fences.

netting width photo

The chain-link is used by both professionals and beginners in construction. It is a good material not only for plastering, strengthening walls and foundations, but also for building an aviary for pets, bird cages or a fence. This is a convenient building material that does not require special skills and additional equipment. The popularity of the netting and welded mesh explains its cost, ease of installation, strength and durability.

The packaging of metal woven mesh provides for the dressing of each roll. It is carried out with wire from low-carbon steel grades with diameters in the range of 1.2-2.5 mm. The requirements for this material are regulated by GOST 3282-74 or special technical conditions 14-4-1563. The use of waste wire is allowed. Binding points - from both edges and in the middle part of the roll. An alternative option is to tie the web to the roll in the same places using the already mentioned wire.

An additional requirement for packaging is wrapping the ends of the roll with paper or wrapping cloth. Requirements for the first are determined by GOST 8828-89, for the second - by GOST 5530-2004. Other acceptable materials for packaging: two types of canvas - glued or quilted and sewn flap from textile waste. Linen and cotton fabrics are not allowed.

For grids of numbers from 5 to 50, it is allowed to replace the packaging with a cross-shaped dressing of the ends of the roll. For this, the wire indicated earlier is suitable. At the request of the buyer, the material is covered with a special lubricant for the purpose of conservation.

The main general rule for labeling and packaging is to attach a label to the end of the bag or roll. It must include the following information:

manufacturer or trademark;

designation of products according to the rules of labeling;

main quantitative indicators:

o roll area in square meters;

o the width and length of the grid (the first is in millimeters, the second is in meters).

Transportation of rolled metal products is carried out either in rolls or in packages. For the formation of the latter, different materials are used - from steel rod of small diameter to special packaging tapes made in accordance with GOST 3560-73. The maximum allowable weight of one package is one ton.

You will be able to buy the Steel mesh netting 50x50x1.8 mm, height 2m from us at the best price in Ukraine. A wide range allows us to quickly and efficiently fulfill any orders, helping you to complete any construction work on time.

No questions about this product, be the first and ask your question.