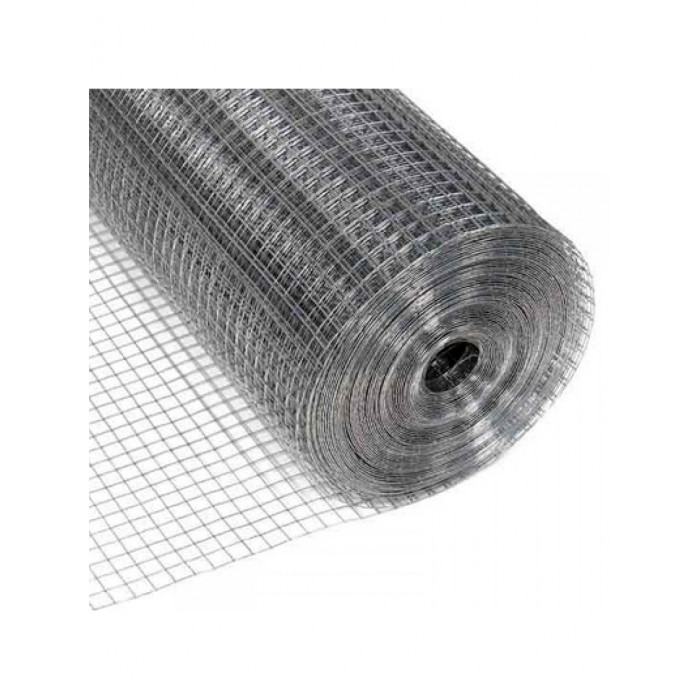

Steel mesh welded cell from 12.5x12.5 to 50x50 mm, diameter 0.6-2.0 mm is a fairly popular and sought-after building material. It is made by spot welding on specialized machines. Steel wire is used as raw material for production. To pack the manufactured mesh, burlap or thick paper is used, while only the ends of the roll are packed.

For the production of mesh, a wire with a thickness of 1.2 to 4 mm is used. According to the shape of the cells, two main types of welded mesh are distinguished - products with square cells and rectangular ones. Rolls have sizes from 1 to 2 meters. The most popular of them are 1-meter and 1.5-meter mesh rolls. The roll length can be 10, 25 or 30 meters.

Welded mesh withstands the effects of temperatures and temperature fluctuations well. At the same time, the product retains all its qualities. The polymer version of the coating for the mesh gives it an attractive look. In addition, the polymer coating provides better protection of the grid from environmental influences and external negative factors. However, ppl mesh is less elastic compared to PVC. The grid welded possesses the high durability and durability. The most durable options in this case are products with the smallest cell size and the largest wire diameter. One of the advantages of welded mesh can be called the minimization of deformations during the operation of products. It can be concluded that welded mesh is an inexpensive, but durable and widely used material.

The scope of welded mesh is wide. This can be explained by the ease of installation and lightness of the material. Most often it is used in the following construction works:

when laying the foundation;

for reinforcing brickwork;

as a casing for the pipeline and obstruction of ventilation openings;

for reinforcing road surfaces and reinforced concrete structures.

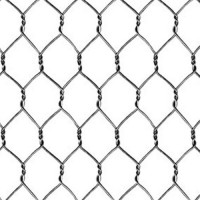

Welded wire mesh has become widespread in recent years. Without its appearance, the technology of prefabricated fences could not have appeared. The product is a perpendicularly arranged metal rods, welded at the intersection points. In the conditions of the modern market, it is advisable to conveyor production of a large number of metal gratings in order to satisfy the demand for this product. At the same time, it is beneficial to have a small production facility in order to independently produce welded steel mesh fabric. Often, handicraft production does without process automation. Steel Mesh Production Workshop Even in industrial production, the degree of automation depends on the diameter of the raw material. Various types of mesh fabric are made from reinforcement, rods and wire. When assembling a lattice from thick reinforcement, it is cut into segments of a certain length, with which the trays of the welding conveyor are filled. Then the machine forms a set of longitudinal rods, which the machine stacks with a given step. The process of manufacturing a fence from a mesh During the operation of the machine, a second tray moves along the laid segments, which feeds and applies transverse rods. After covering the longitudinal rod with a transverse segment, the places of their contact are subjected to resistance welding. Welding of longitudinal and transverse rods After resistance welding of rods, a steel mesh is obtained, which is very durable and designed for long-term operation. Important! When spot or contact welding, the complete absence of rust and mechanical defects is necessary. Since, if they are available, defective material is produced. Experts advise checking the quality of welding, since the purchased steel mesh is valued for the quality and reliability of welding. If the starting material is wire, then the whole process can be fully automated. The wire is continuously unwound from the coil, while the transverse pieces are cut and fed automatically. After that, the welding process takes place. The finished mesh is covered with a protective layer of polymers or coated with a special paint. Steel mesh is used to create mesh panels, as some types of mesh require stiffening ribs for transportation or delivery to the trade. Welded mesh is often used for the manufacture of panel fences. This gives the fence a more presentable appearance, increases the service life of the fence. Types of welded mesh for fences The type of ordinary mesh is familiar to everyone. The steel mesh we are talking about is a rectangular weave of wire and fastened at the intersections with the help of spot welding. Depending on the thickness of the wire rod, the grating is produced with interlacing or overlapping of longitudinal and transverse wires; for this reason, the material is produced in the form of rolls or cuts of a given size. The cells of the lattice are square, rectangular, less often they produce rhombic and trapezoidal shapes. Twisted mesh The wire is used not only single, a wire twisted from two strands is used. In addition, there is a steel mesh made of corrugated wire, which has an increasedtensile strength compared to other types. Depending on the diameter of the wire and the length of the roll, its mass is in the range of 50-500 kg, while the roll is from 15 m to 33.3 m in length, and the height reaches 2 m. When purchasing this material, evaluate the size of its cells, and also remember that the strength of the lattice depends on the diameter of the wire. There are the following types of grids: Welded grid for a fence with a PVC coating. It is usually green in color but can be produced in other colors. The polymer is applied by dipping a welded mesh into it or powder paint is applied in special cabinets. Grid welded galvanized. This coating is applied by electrolytic or hot methods. In addition, the sequence of assembly and coating may be different. Sometimes the grating is fastened, and then galvanized, this can also happen in the reverse order. Mesh rolls are usually packed in strong paper. The steel mesh is not galvanized. It is made of steel wire with a cross section of 1.2-10 mm. It is suitable for the manufacture of fences, but at the same time it is painted by hand with special paint. From China it is delivered packed in polyethylene, and from Ukraine it is simply in rolls. Grid welded with double coating. The first layer is galvanized, and the second coating is a polymer. Such material has the largest margin of safety and a long service life. It encloses such territories as stadiums, schools, playgrounds, parks, ponds, parking lots, private households. Ready-made mesh blocks for a fence Advantages of mesh material as a fence Many people choose a transparent metal fence when creating a fence around a summer house or a rural house. When choosing, the following provisions are taken into account: Welded mesh is lightweight, durable, resistant to various weather conditions; It attracts the possibility of installing a fence with your own hands, with minimal building skills; Satisfies the price-quality ratio of the material used. The contact welding mesh is suitable for those who like to survey the beautiful natural landscape or want to demonstrate their well-groomed area to others. Who wants all the plants to get enough sunlight, and the air of the estate to be fresh and clean. Areas where, in addition to fences, welded mesh is used: In the construction industry, when reinforcing brick and concrete surfaces, to increase the adhesion of the roadway, when plastering walls, when pouring foundations, as well as other works; In fur farms, for the manufacture of enclosures and cages for rodents, birds, dogs and other animals; For the construction of agricultural buildings, in particular for the assembly of greenhouse frames; To create gabions for decorating land in the implementation of landscape design ideas. The use of mesh in the design of flowerbeds Independent production of welded mesh Steel mesh is produced quite simply. Steel wire is cut into certain pieces and welded at an angle of 90 degrees, after which it is ground, cleaned and painted. After that, the material is ready.

Welded steel mesh is manufactured in accordance with GOST 23279-85 from low-carbon steel. A metal sheet is obtained from wire of various diameters, located in mutually perpendicular directions and connected at the points of contact by spot welding. The result is a welded mesh with square or rectangular cells. This type of product can be supplied in the form of rolls and in the form of so-called cards - rectangular sheets of certain sizes.

For additional protection against corrosion, a protective coating can be applied to the finished product. Galvanizing of the welded mesh is traditional, which is carried out by hot or galvanic method. However, the most modern option is to coat the steel mesh with a polymer composition. The service life of such products is several times higher than the service life of uncoated welded steel mesh. The only downside is the high price.

In accordance with the purpose, the welded steel mesh is divided into the following types:

Reinforcing mesh is made from bars with a corrugated surface, the diameter of which is 3-10 mm for light meshes and more than 12 mm for heavy ones. The latter are most widely used when pouring foundations. Light reinforcing meshes are used in plastering works.

The road mesh has found its application as an element that holds back bulk materials in road construction. It is made from wire type VR1 with a diameter of 3 to 5 mm or fittings of classes A3 and A1. The road mesh also increases the service life of the road surface by increasing the resistance of the material to external mechanical loads.

Masonry mesh belongs to the category of light welded mesh and is made from wire with a diameter of 3-5 mm. It is also used in construction as a reinforcing element for wall cladding, it is used as a binder component of brickwork.

In addition, the welded metal mesh willno indispensable for:

the manufacture of cages, fences and aviaries in the field of animal husbandry, since it is durable and lightweight, has a long service life;

arrangement of private territories, gardens and houses: using a welded mesh in the cards, you can make a translucent fence in the garden or enclose the entire territory of the site.

You can buy a welded Steel mesh welded cell from 12.5x12.5 to 50x50 mm, diameter 0.6-2.0 mm from us at the best price in Ukraine. A wide range allows us to quickly and efficiently fulfill any orders, helping you to complete any construction work on time.

No questions about this product, be the first and ask your question.