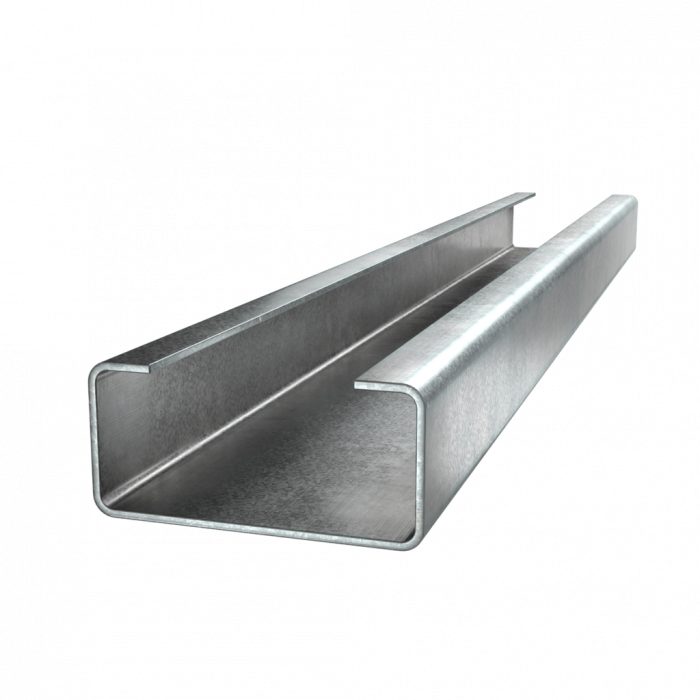

Steel C-shaped profile (steel S235JR, 3PS, 09G2S, S345) is one of the types of bent profile, which is manufactured by cold rolling on an automated line. In appearance, it is somewhat similar to a bent channel, only shelves directed inside the profile are added to the side walls. Due to these shelves, the steel C-profile becomes more stable and thus increases the load-bearing capacity of the profile.

A bent C-shaped profile can be equal-shelf and unequal-shelf. Our production is sharpened for rolled C-shaped equal-shelf profile

When rolling from a profile, we rely on DSTU 8897:2019 and use steels S235JR, 3PS, 09G2S, S345.

The curved profile with a figurative includes a number of advantages, among which the following should be highlighted:

It is convenient when creating a variety of metal structures. Easy and simple to install;

Due to the peculiarities of working with a profile in a metal structure, the specific index of the frame is reduced;

Also with a figurative steel profile is convenient for transportation and storage.

The mounting profile C-shaped is a universal profile that is widely used in modern construction using the LSTK technology, mechanical engineering, shipbuilding and agriculture:

racks for solar panels;

racks in panels of internal and external walls;

columns;

roofing runs;

rafters;

floor trusses and roof trusses;

technological stairs;

wall runs;

floor beams;

elements of the frame and half-timbered BMZ.

C-shaped bent profile is one of the most common profiles used in various areas of production. It is often used in construction, mechanical engineering, electrical engineering and other industries. The production process of C-shaped bent profiles requires certain steps to be followed, which ensure high quality products.

The first stage is sheet metal preparation. Sheets of metal must comply with the requirements of the technical documentation indicated on the drawing. Then the sheets of metal are processed on bending machines, where they acquire the desired shape.

At the next stage of the production of C-shaped bent profiles, finished blanks are processed on roll forming machines. A roll forming machine is used to bend a sheet of metal along an axis to form a C-profile. The machines are equipped with special dies that form a bent profile according to the specified parameters. The machines operate automatically and can process a large number of workpieces in a short period of time.

At the last stage of the production of C-shaped bent profiles, the finished profiles are processed and quality checked. This includes cleaning the surface from contamination, correcting defects and checking geometric parameters. Finished steel bent profiles are packed and sent to a warehouse for further sale.

Thus, the production process of C-shaped bent profiles requires high precision and care at all stages. Products manufactured in compliance with all the requirements of technical documentation and quality standards are reliable and durable.

This is a universal structural element that has found its application in various industries. It is made of metal and has a characteristic shape of the letter "C", the fold of which is made at a certain angle.

Steel bent C-profiles

They can be used to create various structures, including metal frames, fences, pipes and other products. Bent C-profiles have high strength and resistance to mechanical stress, making them an ideal choice for use in many projects.

In our company, we offer a wide range of bent C-profiles made of high quality materials. We guarantee the high quality and reliability of our products, as well as fast and reliable delivery anywhere in the country.

By purchasing from us, you can be sure that you will receive a high-quality product that will last a long time and perfectly cope with the tasks assigned to it.

If you need C-shaped bent steel profiles, please contact us. We are always ready to offer you the best solutions for your project.

Production of a C-shaped profile

In the production of the material, rolled steel with a thickness of 1-4 mm is used, in the manufacture of metal profiles for drywall of all sizes and types, metal up to 2 mm is used. When using rolled products, it is cut into strips (strips) of a given width and wound into rolls

For the production of a C-shaped profile you will need:

Uncoiler of rolled metal.

Machine for longitudinal cutting of metal.

Winder of metal strips in rolls.

Special machine for the production of C- and P-profiles.

For the manufacture of small batches of profiled products, manual or electrified equipment of low power is suitable. For mass production, an electrically driven decoiler with a large capacity with a speed ofunwinding 10-25 m/min.

The next equipment in the production chain is a metal cutting machine. The equipment is used for cutting metal into strips of a given width. The machines cut the roll into several strips at the same time. There are manual equipment for small production volumes, machine tools with an electric drive and an automation unit for the production of medium and large batches of C-profile.

Cutting wheels made of tool steel provide a smooth cut line, free of burrs and other defects. Strip edges do not need additional machining, machines allow you to get high-quality workpieces

Unwinder and cutting machine can be purchased separately or as part of a finished line.

A winder is used to wind the strips into rolls. The equipment ensures the formation of dense and uniform rolls from strips.

The minimum width of 1 strip is 45 mm, the maximum width is 1250 mm, the winding shaft is equipped with a clamp with a pneumatic compensator and separating rollers for simultaneous winding of several strips. The equipment can be equipped with an automatic control unit to adjust the winding speed depending on the performance of the slitting machine.

For profiling the drive and cutting finished products, a special machine with guillotine-type shaped shears is used. The formation of a C-shaped cross section is carried out by rolling a metal strip between rollers of the appropriate configuration.

To cut the finished profile, a reciprocating guillotine with a pneumatic or hydraulic drive is installed on the machine, which does not damage the edges of the product. The equipment is also equipped with an automatic control system for synchronization with other machines of the production line, as well as setting the parameters of finished products. The unit's memory allows you to store up to 10 ready-made programs. Permissible metal profile thickness - up to 2.0 mm, width - up to 350 mm, height - 80 mm, length - unlimited.

The technological process of manufacturing a metal profile provides a sequence of the following operations: a roll of metal is installed on the decoiler and the line is launched. The strip enters the cutting machine, where it is cut into several strips of a given width. Next, the strips are wound into rolls on the winder shaft.

The blanks are fed to the profiling equipment, where strips of C-shaped cross section are formed. Next, the metal profile is cut into segments of a given length. Finished products are collected and stored.

You can buy a Steel C-shaped profile from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.