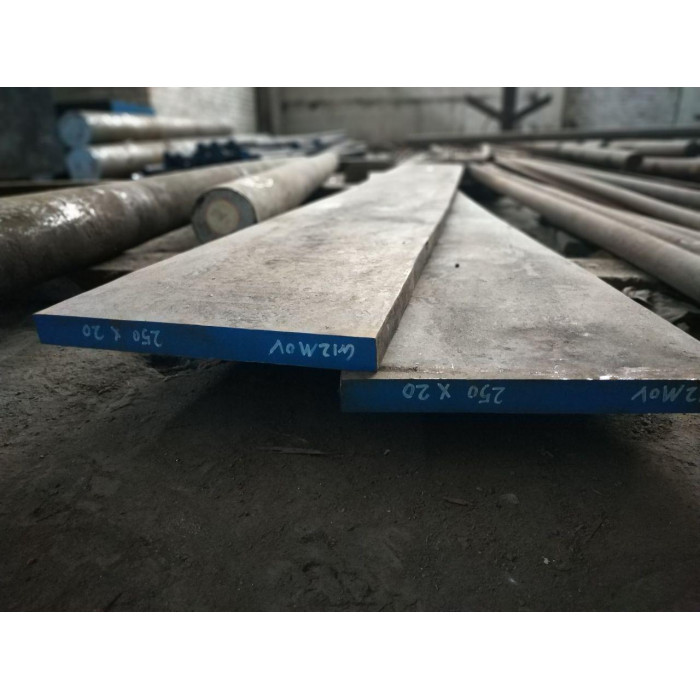

Steel strip tool Art. Kh12MF 40*200(300)mm is a full-fledged rolled metal product in the form of a continuous narrow rectangular sheet. Tool steel strip is a malleable alloy of iron with carbon and other alloying elements. Tool steel, from which strips are made, is the most important material for the manufacture of measuring and cutting tools, as well as various parts of machines and mechanisms.

Tool steel is characterized by high strength and hardness, produced by hot rolling technology and classified into the following categories:

- carbonaceous (reduced hardenability);

= alloyed (increased hardenability);

= fast cutting.

Depending on the purpose of the strip, they are made: measured length, a multiple of the measured length, unmeasured length, and this length ranges from 1.5 to 6.0 m. The section dimensions correspond to the tables of GOST 4405-75.

Carbon tool steels

According to GOST 1435-99 there are high-quality and high-quality.

Quality are designated: by the letter U, which means carbon steel; the figure indicates the average carbon content in tenths of a percent; if the number is followed by the letter G, it indicates the content of manganese. The following grades belong to high-quality steels: U7, U8, U8G, U9, U10, U11, U12, U13.

High-quality carbon tool steels have the letter A at the end of the brand, they are designated: U7A, U8A, U10A and others. This means that this steel smelted in an electric furnace is purer in composition, with a reduced composition of sulfur, phosphorus and other inclusions.

Alloy tool steels

They are manufactured in accordance with GOST 5950-2000, contain 0.9-1.4% carbon, and chromium, vanadium, tungsten, manganese, silicon are used as alloying elements to increase hardenability and hardenability; may contain one or more alloying elements. This type of steel is not intended for welded structures, but only for the production of cutting tools.

Grades X, 9X, 9XS, KhVG, KhV5, Kh12MF are steels for the manufacture of tools used for processing metals and other materials in a cold state.

Grades 5KhNM, 3Kh3M3F, 4Kh4VMFS, 4Kh5V2FS - are used for the manufacture of tools used for metal forming at temperatures above 300 ° C.

High speed tool steels

They are manufactured in accordance with GOST 19265-73, marked with the letter P - rapid, high-speed; the number following it indicates the average mass fraction of tungsten; then there are combinations of chemical elements and their mass fraction. Grades of high-speed steels: R18, R6M5, R6M5FZ, R12FZ, R6M5K5, R9K5, 11R3AM3F2.

Carbon tool steel strips are used to produce tools that will not heat up during work: axes, chisels, saws, chisels, screwdrivers, center punches, pliers, wire cutters.

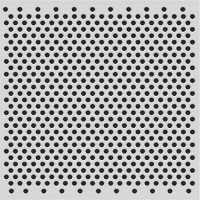

Alloy tool steel grades 9ХС, ХВГ, 6ХВ2С is used for the manufacture of drills, taps, dies, milling cutters, broaches, for technological equipment, for cold metal cutting knives, perforated dies, cut-out dies and punches.

Alloy steel grades 5KhNM, 3Kh3M3F, 4Kh4VMFS, 4Kh5V2FS are used to manufacture hammer and press dies for hot deformation of non-ferrous alloys, hot deformation tools, die casting molds for aluminum and zinc alloys.

High-speed tool steel strips, which combine high hardness and high heat resistance, are used to make cutting tools that require increased resistance and wear resistance.

You will be able to buy the Steel strip tool Art from us. H12MF 40*200(300)mm at the best price in Ukraine. A wide range allows us to quickly and efficiently fulfill any orders, helping you to complete any construction work on time.

No questions about this product, be the first and ask your question.