It's no surprise that modern engineers strive to take these nuances into account even at the design stage for components for land, air, and sea vehicles, not to mention household and especially industrial equipment, which require constant maintenance. The more successful solutions are found in the assembly diagram of numerous individual parts into a single structure, the more efficient its maintenance throughout its entire service life and the lower the financial costs of organizing such processes.

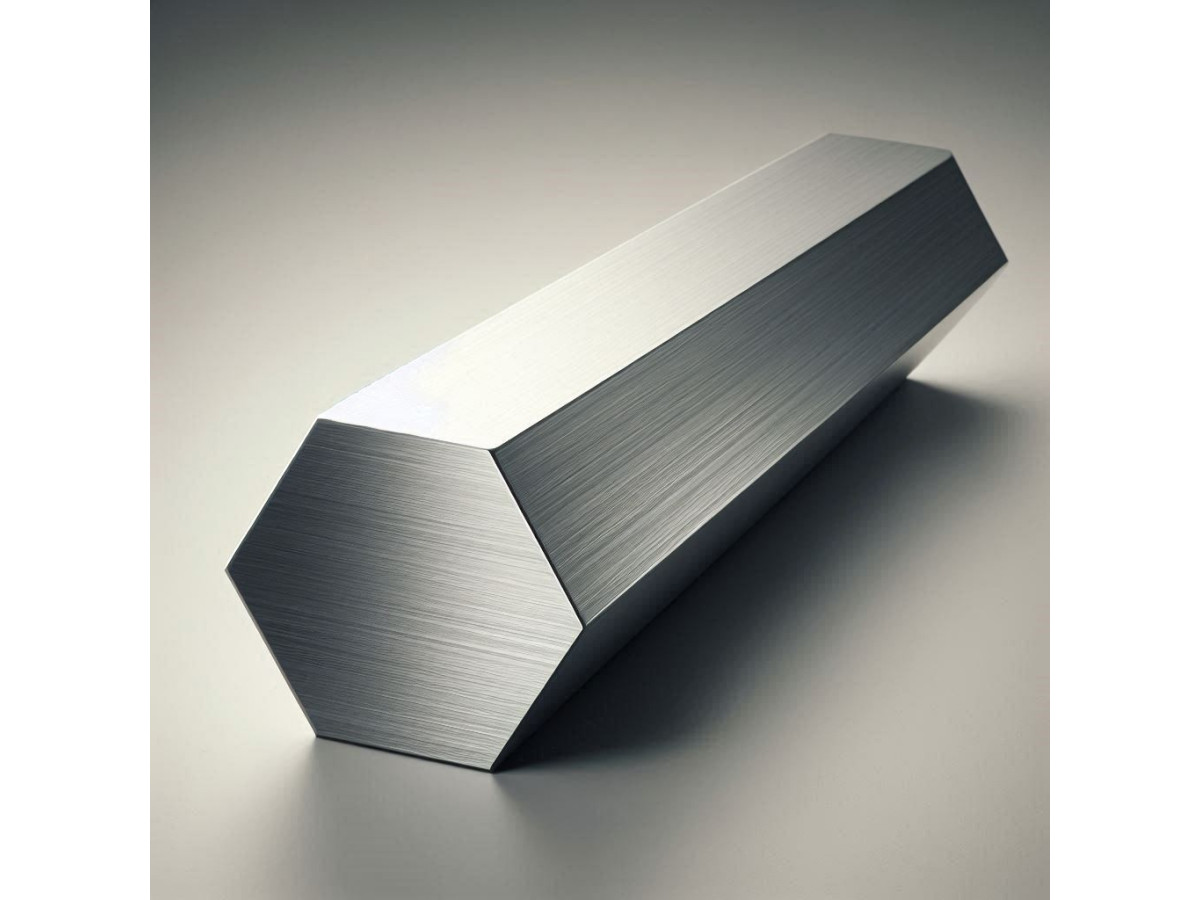

For this reason, threaded connections are now widely used, allowing for the secure attachment of several components to each other or the fastening of individual components to a supporting base. Consequently, there is a strong market demand for materials suitable for their manufacture, of which, according to experts, threaded connections are the most popular calibrated steel hexagon.

It belongs to a group of ferrous rolled metal products and is produced annually in large tonnages by domestic metallurgical plants in accordance with state standards established in the last century. The geometric cross-sectional shape of a regular hexagon has proven to be the most convenient for both screwing one part into another during assembly and unscrewing them during disassembly.

This can be easily seen in the example of billions of hexagonal-headed bolts and nuts produced annually. Unlike round bolts, these nuts are easily and securely gripped with socket and open-end wrenches. Unlike square bolts, sixty degrees of rotation are sufficient for the hand to rotate before the next grip, instead of ninety degrees, which puts greater strain on the muscles controlling hand movement.

Also, the calibrated steel hexagon is brought to almost perfect symmetry relative to the central axis at the metallurgical plant. It significantly contributes to its uniform rotation as a shaft of some unit or during metalworking of the workpiece obtained from it on a lathe.

Analogues of calibrated steel hexagons made from other materials

When it is necessary to obtain a part that is resistant to corrosion and various reagents, often the source material chosen is stainless steel hexagon Among its characteristic distinctive features, the following are worth noting:

- It has a significantly higher cost due to the introduction of expensive alloying components during the steel smelting process, each of which improves one or several properties useful for practical application.

- Resistance to undesirable oxidation-reduction reactions is provided by chromium, which forms a thin, highly inert oxide film on the surface that adheres tightly to the metal. Its addition also significantly increases the material's hardness and wear resistance, significantly extending the life of the finished product but creating certain difficulties during manufacturing.

- The presence of nickel in the alloy significantly expands the permissible temperature range.

Analogues made from non-ferrous metals are also in steady demand.

Brass hexagon

Composed primarily of copper brass hexagon It is also resistant to mineral acids, alkalis, and strong salt solutions, making it suitable for use in the development of equipment for the food and chemical industries. However, this material is much more popular in electrical engineering due to its high electrical conductivity.

Bronze hexagon

It has very similar properties bronze hexagon, although its ductility is significantly inferior to the previous method. It is most often used where friction between moving parts in contact must be reduced due to the antifriction properties of the material used.