To keep moving parts within the space allocated for their placement, it is always necessary to use guides that limit lateral displacement, as these guides themselves are not in a stable equilibrium and, with the slightest deviation from the norm, will drift further and further away from it over time, instead of returning to their original position. On the other hand, no matter how the limiting assemblies are designed, for fundamental reasons, friction cannot be completely eliminated in the presence of gravity, so engineers regularly have to select the surfaces of which parts should bear it.

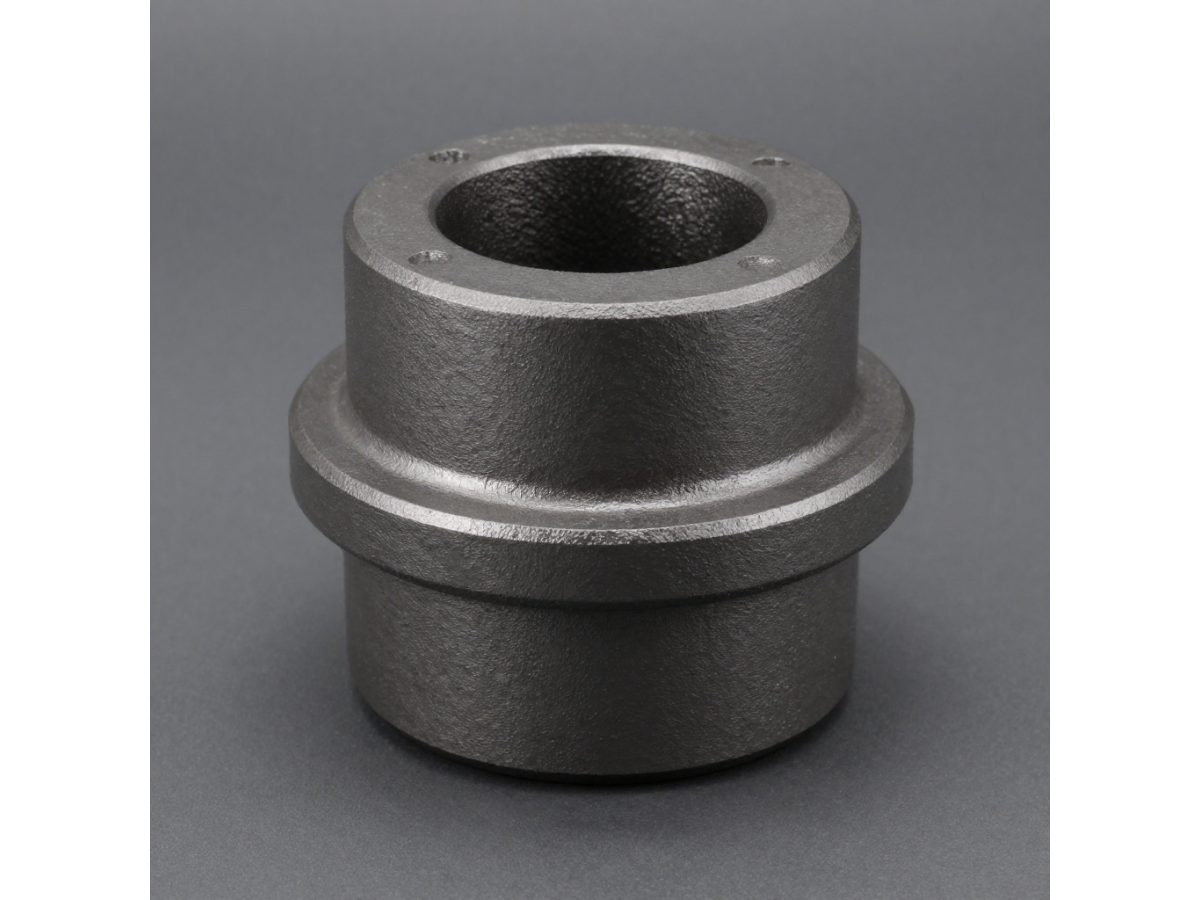

In the search for the optimal solution, it is necessary to consider not only purely technical aspects but also due attention to economic considerations. For example, ball and roller bearings completely eliminate wear on both the housing they are intended for installation on and the rotating shaft itself, replacing which carbide races are gradually worn down. However, their relatively high cost makes their use far from always justified. On the contrary, cheap cast iron bushing It guarantees the safety of the complex and expensive-to-manufacture housing from failure, which cannot be said about the rotating element itself, which it prevents from lateral displacement in a direction perpendicular to the central axis.

The final choice from the available options usually depends on several key factors:

- First and foremost, these are design features that influence the ability of a given component to perform its intended functions. If this goal cannot be achieved for a number of objective reasons, then the option should be discarded, regardless of any other benefits.

- Economic feasibility is often the second most frequently cited evaluation criterion. Preference is usually given to the option that minimizes the total cost of creating the mechanism and maintaining it throughout its operational life.

- In some cases, the reliability of the unit becomes more important, which is especially true for special-purpose equipment, military vehicles, and spacecraft. In these applications, financial costs become secondary, as the tasks being solved have virtually no connection to commercial activity.

Having carefully weighed all the pros and cons, an experienced engineer, when developing new equipment, is constantly forced to choose between rolling and plain bearings. If he chooses the latter, he must determine whether it is better to use a cast iron bushing or an equivalent made of another material in each specific case.

Cast iron bushings analogs made from other materials

There are quite a few cast iron bushing alternatives mass-produced in accordance with state standards, not to mention the ability to manufacture such parts on metal-cutting machines for custom projects. Of this variety, two are the most widely produced, and they deserve a more detailed discussion.

Brass bushing

More expensive in price brass bushing While not inherently more reliable than cast iron, it does significantly extend the service life of the moving part in contact with it. This is achieved primarily due to the increased wear of the guide part itself, which is made of a relatively soft material. Therefore, to prevent severe vibration, it is necessary to promptly replace it with new ones. Also, by using copper as a base component, which has high thermal conductivity and is resistant to chemically active substances, damage to smooth friction surfaces due to overheating or contact with aggressive reagents is prevented.

Bronze bushing

Has very similar characteristics bronze bushing However, there are also significant differences for certain applications. For example, some grades of bronze are incapable of generating sparks under mechanical stress, and therefore better meet fire safety requirements.