At the stage of developing new models of mechanisms and machines, engineers have to solve many complex problems. To operate effectively, each individual part must successfully perform its specific function. The destruction of at least one leads to the failure of the entire unit. The operation of long production lines, the technological cycle of which includes broken equipment, often stops, which causes serious economic damage, and sometimes, sadly, leads to the death of people. A similar situation is observed among architects designing residential buildings and technical structures. Therefore, the choice of raw materials for the manufacture of any element must be approached thoughtfully and with special care. There are a huge variety of materials on the modern market, for example corrugated steel sheet, and you can almost always purchase the optimal one.

General characteristics of black rolled sheets

It is very widely used as a structural material and raw material for the manufacture of various parts of black sheet metal, and its annual production by Ukrainian metallurgical plants amounts to millions of tons. It is easily reprocessed on special metalworking machines that perform the following operations:

- cutting into pieces of required sizes;

- flexible at any angle;

- stamping to obtain curved surfaces of complex shapes;

- cold and hot forging on forging presses;

- drilling holes;

- grinding and polishing in order to eliminate roughness that is unnecessary for some needs.

Structural steel, freed from excess impurities of sulfur, phosphorus and carbon, has no brittleness, so chips and cracks do not occur during impacts. High strength and resistance to deforming forces under weight or pressure created by atmospheric air flows ensures a long service life and a high degree of reliability.

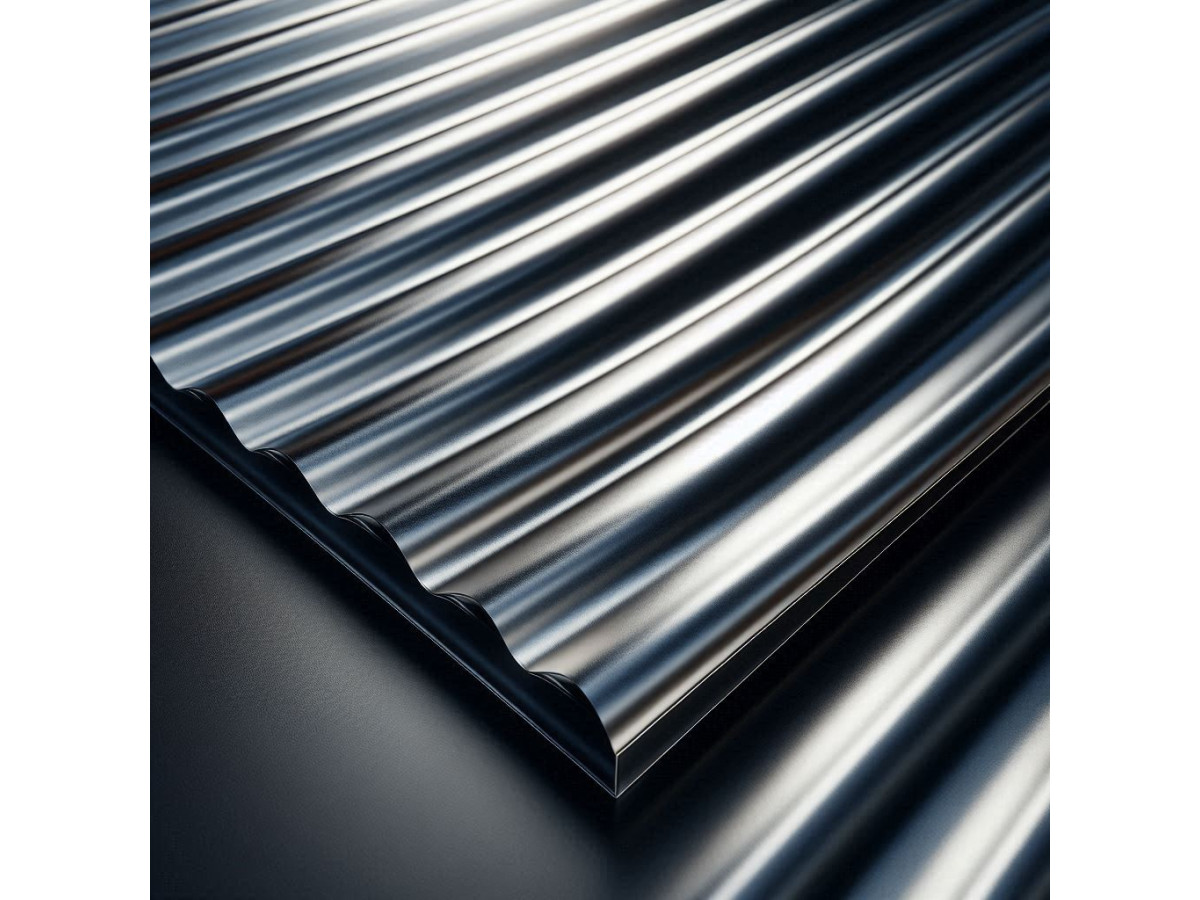

Why was corrugation of steel sheets needed?

Absolutely flat steel sheets have a very smooth surface, which in the vast majority of cases turns out to be an undoubted advantage. However, to successfully solve a number of specific problems, it is simply necessary to increase the friction force to eliminate unwanted slippage. The problem is so great and widespread that the fight against it begins already at the stage of production of the source material. One way to deal with it is to corrugate the metal, which was performed immediately on a rolling mill, which turned out to be more economically feasible than carrying out such an operation with even blanks on stamping presses.

There are many examples of the use of corrugated steel sheets. To understand the nuances, it is reasonable to analyze in detail the most characteristic ones:

- Metal ladders are an integral part of firefighting equipment; they are found everywhere in factory workshops and are indispensable for access to crane cabins and observation and technological platforms located at high altitudes. For safety reasons, it is necessary to take all possible measures to minimize traumatic situations. When moving along them, shoes must maintain a secure fit with the supporting surface, so for the manufacture of steps you need to use not smooth materials, on which you can slip even in dry weather, but corrugated ones, ensuring good contact even in rain and snow.

- For similar reasons, overpasses for inspection, maintenance and repair of vehicles are designed.

- Covering recesses for laying communications in the presence of pedestrian traffic along them also need to ensure safety, so the described material can often be found in underground passages and metro stations right under your feet.

Choosing the name of corrugated steel sheet to solve specific problems

When choosing a name for a corrugated steel sheet, you should firstly be guided by the importance and responsibility of the task at hand. Assessing the impact of differences on certain functional features will help overcome hesitation when making a decision.

Influence of corrugation depth of steel sheets on friction force

The rubber of a shoe sole or car tire is deformed under pressure on the support. Its own elasticity and thickness impose restrictions on the permissible indentation, therefore, in order to accurately follow the contours of the surface for maximum adhesion, it is necessary to select the optimal depth of corrugation.

Important appearance features for design projects

Designers can choose from checkered, diamond-shaped, lentil patterns, as well as corrugated stainless steel sheets allowing, independently or in combination, to improve the aesthetic perception of structures.