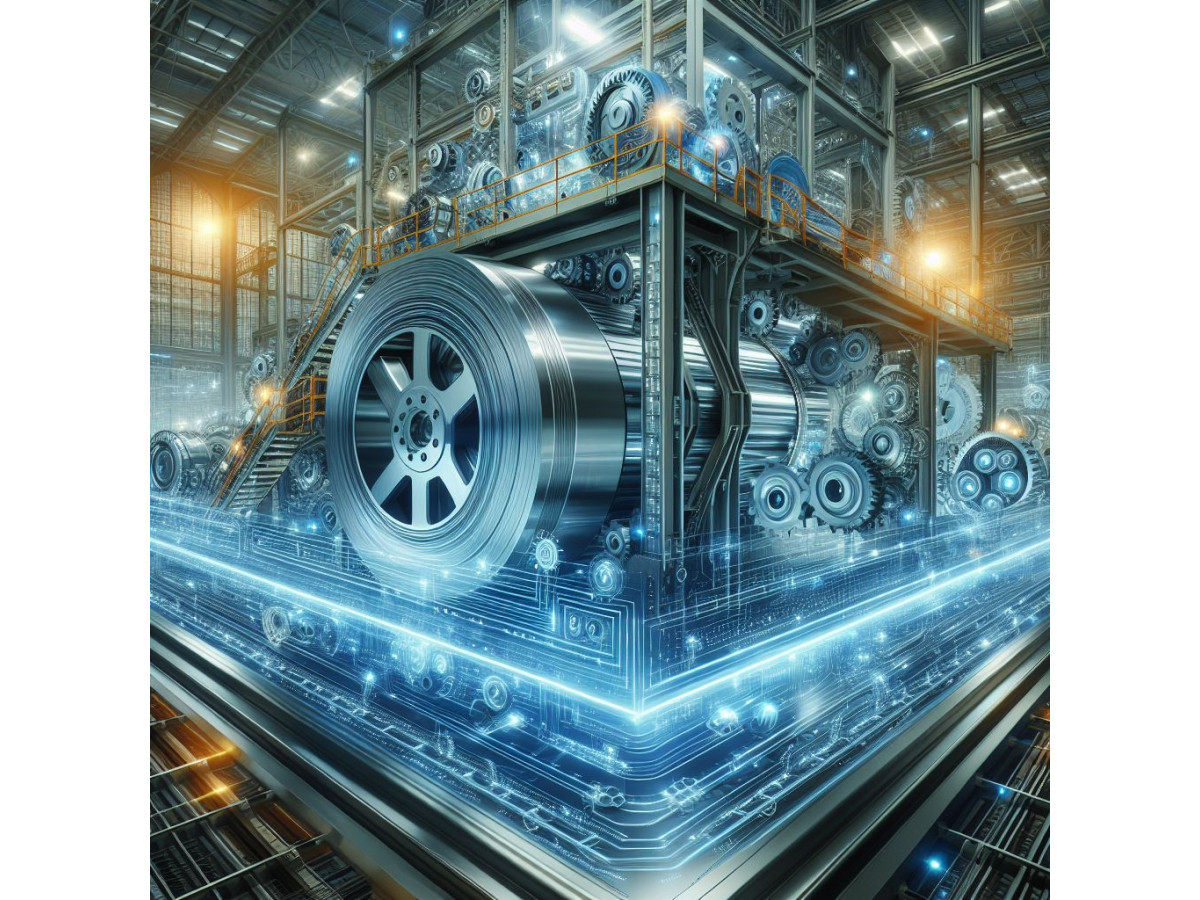

Modern technologies in rolled metal production include a variety of methods and processes aimed at improving efficiency, quality and environmental sustainability. Metal rolling Thanks to the use of modern technologies and specialized equipment, it is becoming increasingly high quality and reliable. It is very important to contact a reliable place to obtain a guarantee of compliance with basic standards. This approach guarantees high quality operation, because production takes into account absolutely all the nuances.

Main types of rolled metal production technologies and their features

Each type of rolled metal has its own unique features and manufacturing options. Among the most common options in this area are:

- Casting, which is the process of forming metal parts by pouring molten metal into a mold. It is used for the manufacture of large and complex parts, including, for example, car bodies, engine parts and machine parts.

- Rolling, which is the processing of metal ingots using rollers to produce sheets, strips, wires and other shapes. It provides production of sheet metal, steel beams, pipes and other forms of rolled metal.

- Electrolytic deposition is an important method. A method of coating a metal with a thin layer of another metal using an electric current. The main area of operation of this method is the creation of decorative coatings, anti-corrosion layers and increased conductivity.

- The use of electrolytic processes to remove oxides, contaminants and other undesirable elements from the surface of a metal. They are used to prepare the surface before coating, improving the appearance.

- Hot firing involves the process of heating metal to a high temperature to improve its mechanical properties. This technique is used to improve the strength and resistance to deformation of carbon steels.

If you choose a reliable base for ordering metal, you can count on compliance with the declared characteristics, which is also important.

Popular modern production techniques

Adding material layer by layer to create 3D metal objects is becoming increasingly common nowadays. It is used for the manufacture of complex and innovative parts, prototyping and production of unique designs. A modern plant can organize the production of high-quality metal using this method.

Plasma cutting is also in demand. This is a process in which a plasma torch is used to cut metal. Thanks to this method, either a ton of metal or any other quantity can be produced.

The introduction of technologies and production methods aimed at reducing the negative impact on the environment is becoming very popular. They are used because reducing emissions, improving energy efficiency, and recycling waste are becoming really important.