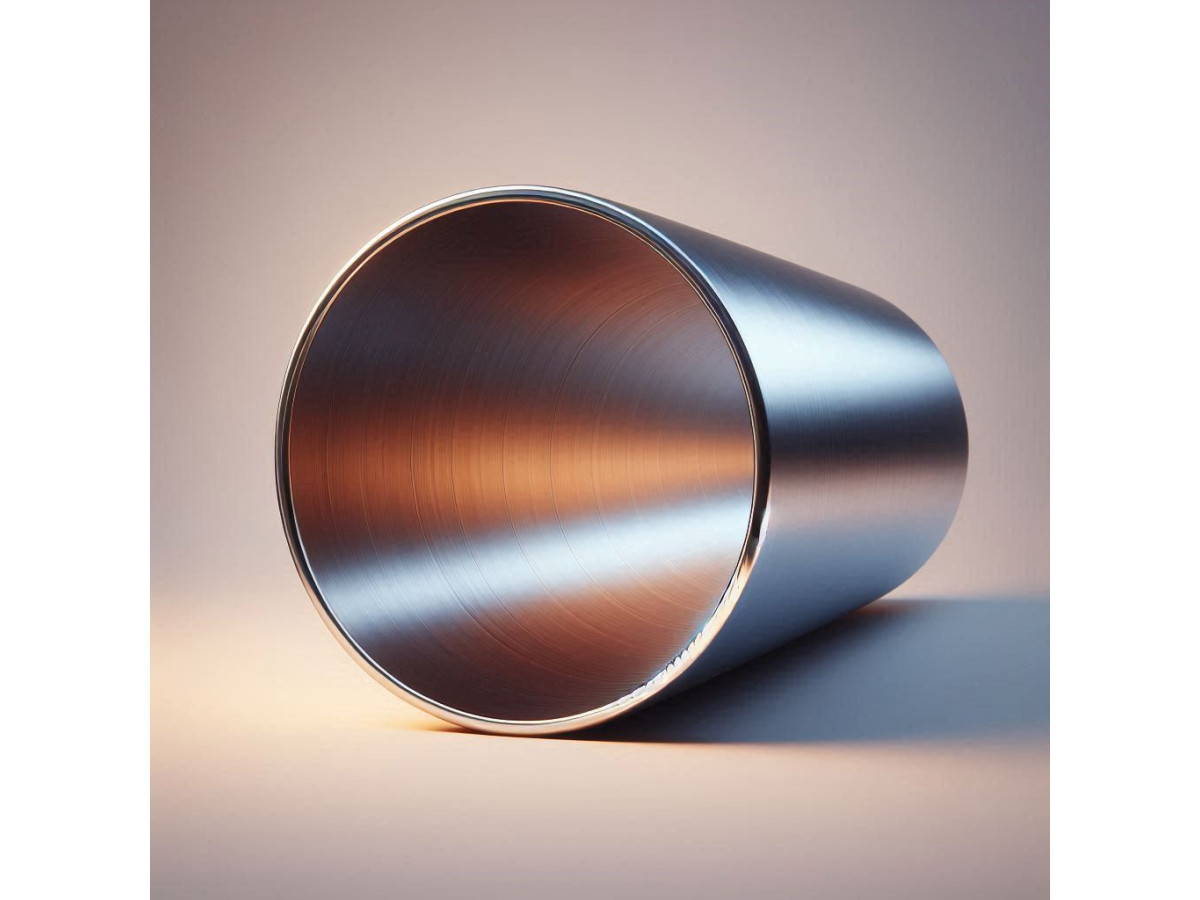

In Ukraine, as in other relatively technologically advanced countries, more than half of the total freight flow measured in ton-kilometers is carried by pipeline transport. For clarity, the branched network can be compared to an ordinary tree, each part of which can be assigned a section corresponding to its functional purpose. The root absorbs moisture from the soil and combines the role of an intake and a pressure pump, the trunk is the central main line, the large branches adjacent to it are lateral branches, the sunken ones growing from them, the even thinner risers and distributions following them, and the leaves and fruits are consumers of water extracted from the ground. Such a schematic representation clearly demonstrates the change in diameters when moving from one level to another, the throughput capacity and the internal pressure required to ensure it. Accordingly, it is possible to evaluate the technical requirements imposed on the materials for sections of each level. For a main line starting its journey from a pumping station, the best choice would be hot-rolled or cold rolled round steel pipe, since these types of ferrous rolled metal products have the qualities necessary for this.

The main features include the following:

- Solid-drawn walls have no seams, therefore they have the highest strength among all varieties, and its distribution at all points is uniform. This causes the absence of weak points and allows the pressure of the working medium to be brought up to the limit values required to create a cylinder sufficient for rupture from each individual alloy with the same thickness.

- To deform metal on a rolling mill into a cylindrical product, it is necessary to apply great efforts to push it through, which entails increased energy consumption. Also, some energy costs will be needed for recycling the resulting waste, so the material is more expensive in terms of cost than analogues manufactured using less energy-intensive technologies. However, due to its greater reliability and durability under significant loads, its use, despite the increase in capital investment at the start, due to long-term operation without the need for frequent maintenance and repair work, provides solid savings at the finish.

- For assembly operations, conventional manual electric arc welding with alternating current in open atmosphere conditions is sufficient.

If, in order to implement a project in compliance with all the stipulated requirements, it is permissible to use cheaper analogues instead of round cold-rolled steel pipes, then, of course, it is better to give preference to them.

Analogues round cold rolled steel pipes

If round cold-rolled steel pipes are most often the optimal choice for main lines or, in our comparison with a tree, for its trunk, then for other areas their analogues may be preferable, which are worth briefly discussing separately.

Round electric welded steel pipe

For the rather thick and straight branches adjoining the trunk, a cheaper round electric welded steel pipe is quite suitable. It is manufactured by metallurgical plants in cycles of several simple and low-cost operations:

- rolling iron into a flat strip of small width and thickness;

- rolling it into a long hollow cylinder;

- fastening of aligned edges by automatic electric arc welding.

This type of wall structure, unlike a seamless one, is capable of withstanding lower pressures and is too susceptible to bending of finished products at a large angle, as a result of which the seal may be broken due to a ruptured seam.

Water and gas steel pipe

Unlike the previous type of rolled metal, water and gas steel pipe has a spiral seam rather than a straight longitudinal one, which is more resistant to bending. Its formation is somewhat more expensive, but the material is able to replace seamless when creating small-diameter end wiring with many 90-degree turns for connecting heating radiators, mixers and other consumer devices.

Boiler tube made of corrosion-resistant heat-resistant steel

Some equipment is not included in the described scheme, since the space it occupies is located before the pump or tree root. For example, in centralized and individual hot water heating systems, boiler tube made of corrosion-resistant heat-resistant steel It is the most expensive of those described, but it can operate at very high temperatures without rusting.