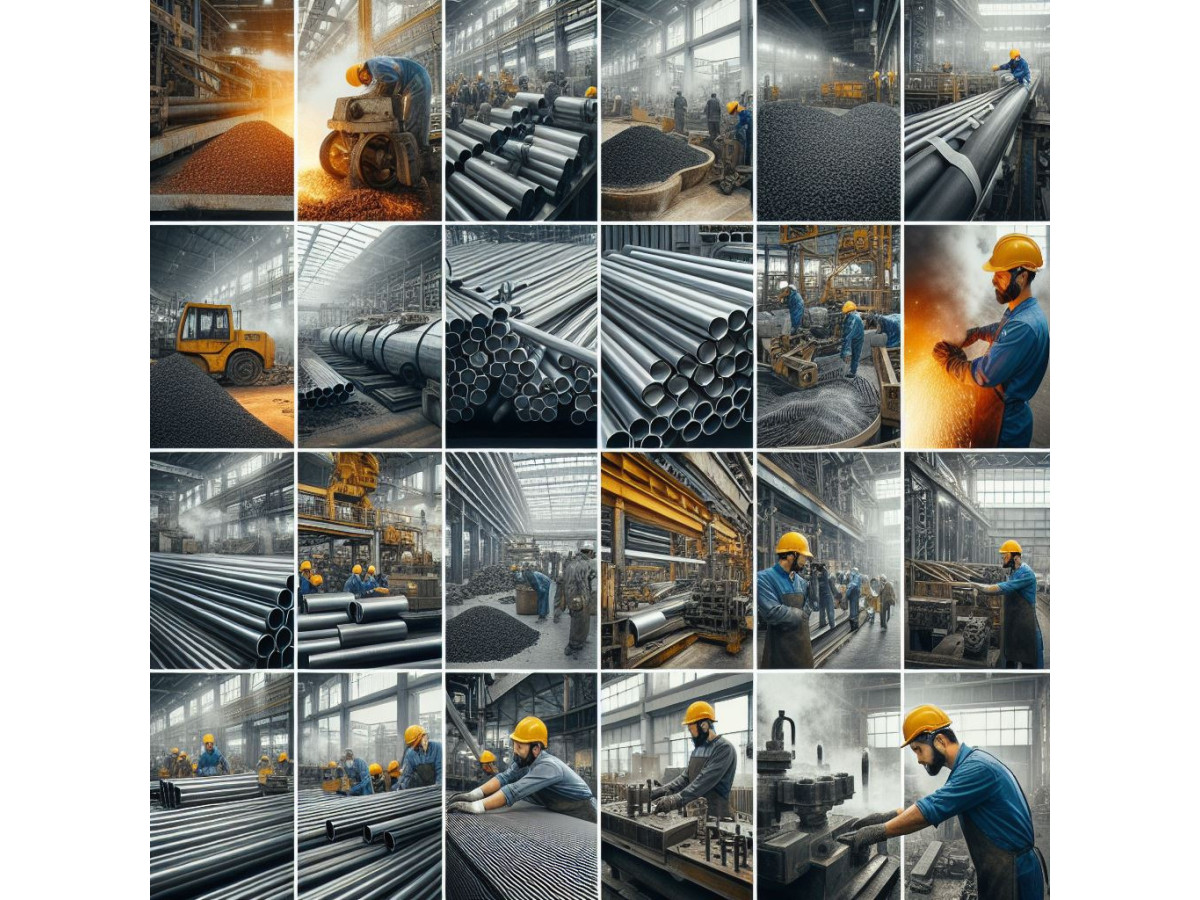

Production of pipes from ferrous metal is very popular today, because you can get high quality and reliability for relatively little money. But it is still important to use a variety of innovative technologies in this area, which will allow you to get all the opportunities for development and achieving the desired result. Online https://ukrstarline.ua/en/black-rolled-metal it is easy to find more interesting details about such products.

Modern technologies and equipment to increase the level of production efficiency

Technological innovations in the production of ferrous metal pipes can contribute to improved productivity, quality and sustainability of processes. The use of modern electric heating furnaces makes it possible to precisely control the temperature during the production of pipes. This not only ensures homogeneity and quality of the material, but also reduces energy consumption. That is why all modern and responsible manufacturers try to install appropriate equipment.

The use of precise forming and stretching methods can improve the accuracy and uniformity of pipe thickness. This is important to ensure high strength and stability of pipes during operation. Pipe production includes a welding stage. Improvements in welding techniques, such as the use of automated welding systems and the use of laser or plasma welding, can improve the quality and efficiency of this process.

What else is being done in terms of innovation in the production of ferrous metal pipes?

There is always some kind of movement here that allows you to actively develop and get quality results. Among the most important details here can be noted:

- The production of pipes using new components and technologies can lead to the creation of pipes with high strength and wear resistance, which can be important in the context of various applications.

- The use of software for mathematical modeling and data analysis can contribute to the identification of optimal production parameters, which leads to process optimization and cost reduction.

- The implementation of IoT technologies can provide real-time monitoring and control of production processes. This allows production problems to be identified and corrected, thereby increasing efficiency and quality.

- Implementation of energy-efficient technologies and systems in production can help reduce energy costs and CO2 emissions. This may include the use of energy-saving lighting systems, improvement of heating and ventilation.

Everything is very important for the stable development of this area.