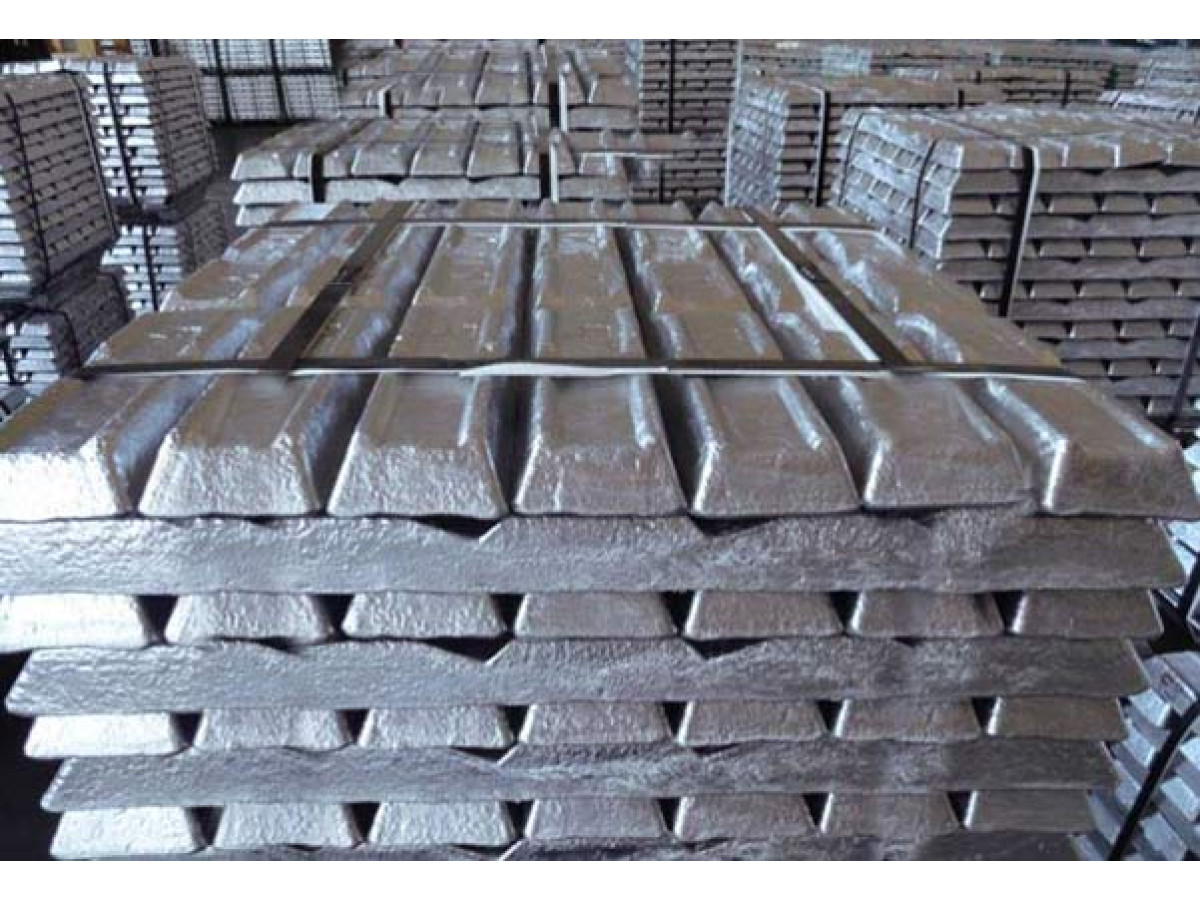

Aluminum is one of the most important metals used in modern industry and construction. And one of the first stages of aluminum production is the production of pigs - a kind of “raw material block” for further processing. Let's dive into the world of aluminum alloy, consider the features of pigs and their role in production.

Types of aluminum ingots

Aluminum pigs are one of the primary products in the production of aluminum alloys. There are several main types of aluminum ingots, each of which has its own characteristics and applications:

- Primary pig: This is pure aluminum pig, which is produced by melting aluminum oxide with the addition of cryolite and graphite. This pig is the starting material for the production of aluminum alloys of various grades and classes.

- High-quality pigs: This is an aluminum pig containing a certain amount of impurities and alloying elements that give the material the necessary properties. Grade pigs are used to obtain specific characteristics of the alloy.

- Foundry Pig: This pig is designed for casting aluminum alloy parts. It contains certain impurities that ensure good fluidity and quality of castings.

- Recycled Pig: This is a recycled aluminum material obtained from the recycling of waste and shavings of aluminum products. Recycled pigs can reduce production costs and reduce the environmental burden.

Each type of aluminum ingot has its own characteristics and applications, and the choice of a specific type depends on the specific requirements of production and the final product.

How to choose aluminum ingots?

The choice of aluminum ingots depends on several key factors, which are determined by the specific requirements and characteristics of your production. Here are some important aspects to consider when choosing aluminum ingots:

- Alloy Type: Determine what purpose you need the aluminum alloy for. Depending on the specific application, select a pig containing the appropriate impurities and alloy elements.

- Chemical composition: When choosing aluminum ingots, pay attention to its chemical composition. Make sure that the content of impurities and alloying elements meets your production requirements.

- Shape and Dimensions: Consider the required dimensions and shape of the pig so that it can be easily used in your equipment or production process.

- Quality: Buy aluminum ingots from reliable and quality suppliers to ensure they meet standards and specifications.

- Environmental Considerations: Consider environmental responsibility when choosing aluminum ingots. Prefer recycled ingots to reduce environmental impact.

- Price: Compare prices from different suppliers and choose the best combination of quality and cost for your production.

Before making a selection, we recommend consulting with materials scientists or supplier representatives for additional information and guidance on selecting the appropriate aluminum ingot for your specific needs.

Conclusion

Aluminum ingot is one of the key materials in the aluminum industry and plays an important role in the production of various products. The correct selection of aluminum ingots is of great importance to ensure high quality and successful completion of the production process. Let's consider additional aspects that need to be taken into account when choosing aluminum ingots:

- Thermal Properties: It is important to consider the temperature characteristics of aluminum ingots, especially if a specific melting or hardening range is required for a particular manufacturing process.

- Manufacturing Parameters: Consider your equipment and production technology to select the aluminum ingot that will best suit your production processes.

- Controlling Structural Features: Pay attention to the degree of crystallinity and microstructure of the aluminum ingot, as these parameters can affect the mechanical properties and processing of the material.

- Compatibility with Other Materials: If your production uses other materials or alloys, make sure the pig you select is compatible with them to produce quality, durable products.

Based on these additional aspects, it is necessary to carefully analyze production requirements and base your selection of aluminum ingots on specific production conditions and goals. It is recommended to consult with experts in the field of materials science and production to receive professional recommendations and choose the best aluminum ingot option for your business!