Stainless steel wire is one of the main construction and manufacturing materials, which has found wide application in various industries due to its corrosion resistance, strength and versatility. Let's take a deeper look at this material and find out why it is one of the most popular in its class.

Types of stainless wire

Stainless steel is an alloy that contains chromium, which makes it resistant to corrosion. Stainless steel wire is used in various industries such as kitchen utensils, construction, wire and cable manufacturing, medical industry and others. Here are the main types of stainless wire:

- Stainless Steel Alloys: Stainless steel wire can be made from various stainless steel alloys such as AISI 304, AISI 316, AISI 316L and others. Each alloy has its own characteristics, such as corrosion resistance, mechanical properties and strength.

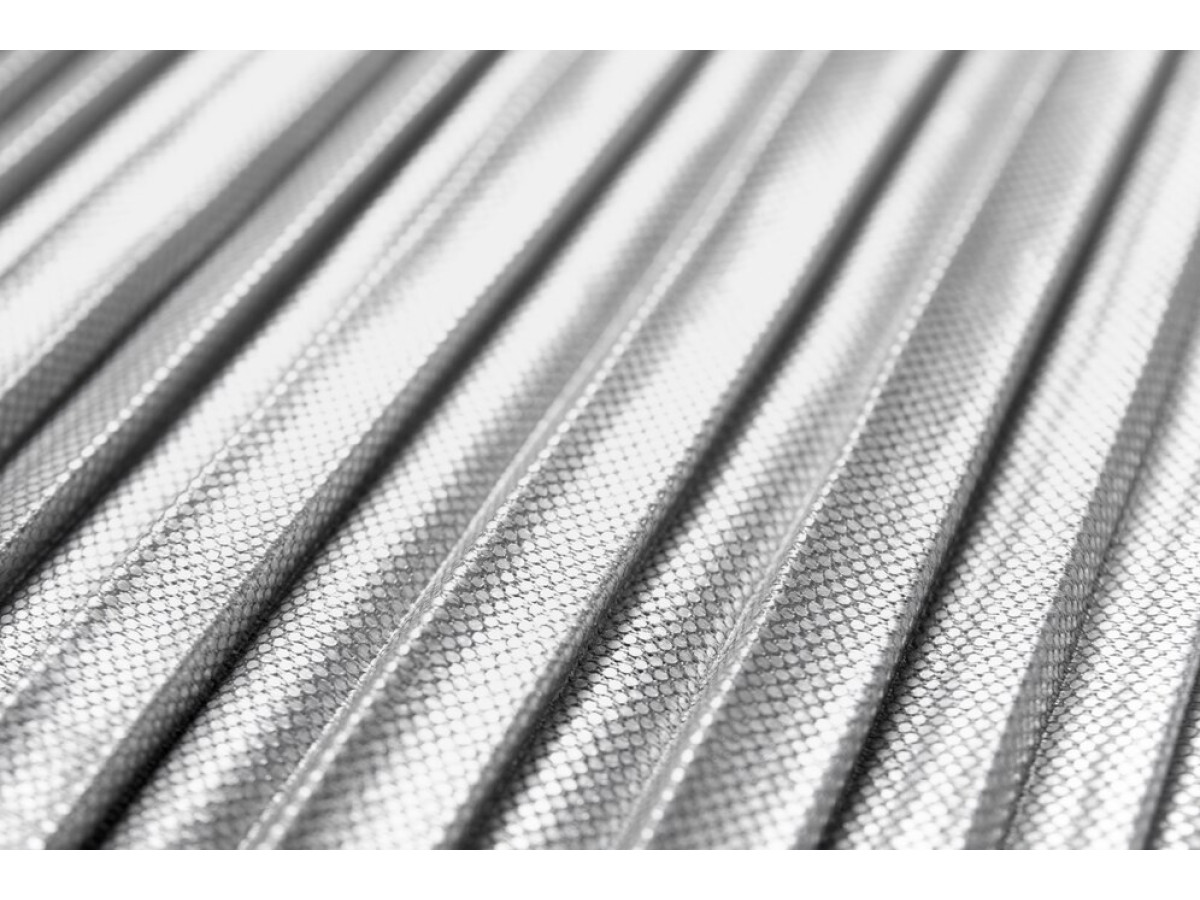

- By Surface Type: Stainless steel wire can be classified by surface type, such as polished, matte or oxidized, depending on the requirements and preferences of a particular application.

- By diameter: Stainless steel wire can have different diameters, ranging from very thin (for example, for medical instruments) to thick (for example, for fastening structures).

- Shape: Stainless steel wire can be produced in various shapes such as round, square, flat and others depending on the specific application requirements.

- According to properties: Depending on the properties and characteristics of the stainless steel alloy, wire can be divided into soft, hard, with high mechanical characteristics and others.

These are the main categories and types of stainless wire, which can be selected depending on specific needs and application conditions. If you have specific requirements or questions regarding stainless steel wire, do not hesitate to contact us for more information.

Advantages of using stainless wire

The use of stainless steel wire provides many benefits that make it a popular choice in various industries. Here are some major benefits of using stainless wire:

- Corrosion resistance: Stainless steel wire is highly resistant to corrosion due to the presence of chromium in the alloy. This allows the use of stainless wire in conditions of high humidity, aggressive environments and in contact with various chemicals.

- Durability: Stainless steel wire is highly resistant to wear and retains its quality characteristics for a long time. This allows the use of stainless wire under conditions of increased load and exposure to various factors.

- Hygienic: Stainless steel wire is easy to clean, is not susceptible to contamination and provides a high level of hygiene. Therefore, it is widely used in medical institutions, the food industry and other areas where high sanitation standards are required.

- Attractive appearance: Stainless steel wire has a shiny surface, which gives the products an aesthetic appearance. It is used in the production of decorative elements, furniture, sculptures and other products where appearance is important.

- Versatility of application: Stainless steel wire is widely used in various industries due to its unique characteristics. It is used in construction, equipment manufacturing, springs, fasteners, meshes, wires and many other fields.

- Ease of processing: Stainless steel wire is easy to process: bend, weld, cut and shape as needed. This makes it a convenient material for the production of various products and designs.

These advantages make stainless wire a popular and in-demand material in various industries and construction.

Conclusion

Stainless steel wire does play an important role in many industries as it has several advantages that make it a desirable material for various applications.

Reliability, durability and a high degree of resistance to aggressive environments make this material indispensable in various production and construction processes.

It is also important to remember that choosing the right stainless wire to suit the requirements of your production or construction process will achieve optimal results, improve the quality of the final product and increase production efficiency. Therefore, a thorough analysis of the requirements and careful selection of materials are key points when working with stainless wire!