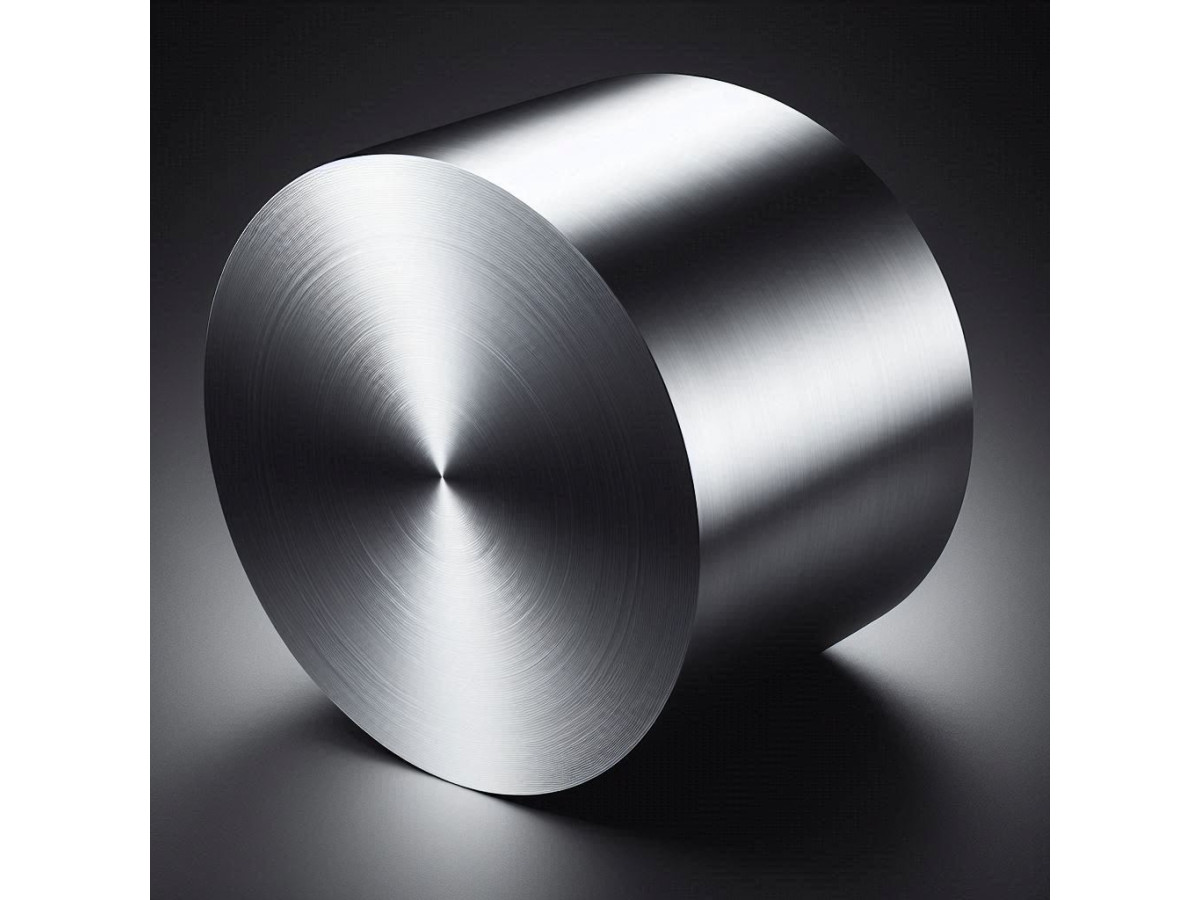

Steel calibrated circle is a high-quality rolled metal product having a round cross-section and made from steel by cold or hot rolling. It is subsequently subjected to sizing, a process in which the rod is machined to achieve precise dimensions and improve surface quality.

Production stages

The steel wheel manufacturing process includes several key steps, each of which plays an important role in ensuring the high quality and accuracy of the finished product:

- Preparation. The steel grade is selected depending on the required characteristics of the future finished product. The most commonly used are St3sp, 08G2S, 10G2S, 20G2S and 35GS. The workpiece is heated in special ovens. Heating facilitates further processing of the metal, making it more ductile.

- Rolling. The workpiece passes through a series of rolling machines, where it is gradually reduced in diameter and stretched into a long rod. Rolling is performed in several stages.

- Edit. After rolling, the wheel may have curvature and defects. The straightening process involves mechanical processing on special straightening machines under high pressure.

- Calibration This is the main production stage during which the circle is given the required size and shape. Calibration is carried out by passing the wheel through special calibrating mills with rollers. The process ensures high diameter accuracy and helps to increase the mechanical strength of the material due to cold deformation.

- Cooling. The hot workpiece is cooled under controlled conditions to prevent thermal stress and achieve the desired mechanical properties. Cooling can be performed in air or water, depending on the requirements for the structure and properties of the material.

Strict quality control is carried out at every stage of production. The finished circle is checked for compliance with standards for size, accuracy, surface, mechanical properties and other indicators. The use of modern equipment and technologies allows us to produce high quality steel calibrated circles that comply with GOST, ASTM or ISO.

Types of rolled metal

A wide range of rolled metal in the form of steel calibrated circles is presented by the company Ukrstarline. Products can be purchased via the link https://ukrstarline.ua/ru/chernyj-metalloprokat/stalnoj-krug/stalnoj-krug-kalibrovannyj. Steel calibrated wheels can be classified according to several parameters: accuracy, surface treatment method and steel grade.

High-precision calibrated metal products are marked KP. It is used in applications where high precision and reliability are required, such as in mechanical engineering and machine tools. Normal accuracy is designated by the letter K. Steel wheels in this category are used in less critical applications where dimensional accuracy is not a priority, such as construction and metal fabrication.

According to the method of surface treatment, the circle can be hot-rolled or cold-rolled. The first has an untreated matte surface with scale. It is more affordable in price. The second one undergoes additional processing steps, grinding or polishing, which ensures the smoothness and precise dimensions of the product.

For the manufacture of the circle, general purpose carbon steel can be used, which is characterized by good weldability and machinability. Low-alloy steel with increased strength and corrosion resistance is also used in production. This metal is necessary for operation in aggressive environments. The most expensive wheels are made of alloy steel with high strength and wear resistance.

Advantages of steel circle

Calibrated steel circle has a number of advantages that make it a popular material in various industries:

- High precision, reducing the need for additional processing.

- Good machinability. The material can be easily machined, which makes it possible to produce complex parts with minimal time.

- Durability and reliability. The calibrated circle withstands high loads and deformations and ensures the durability of the products.

- Durability. With proper operation and protection against corrosion, rolled metal can serve for decades without significant loss of performance characteristics.

In addition to the listed advantages, the steel circle has other advantages. It is available in a wide range of diameters, is easy to weld and cut, and is environmentally friendly.

Due to its advantages, rolled metal of this type is used in the manufacture of machine parts and mechanisms, reinforcement of reinforced concrete structures, production of pipes and parts for oil and gas equipment. It is often used in agriculture and the food industry.