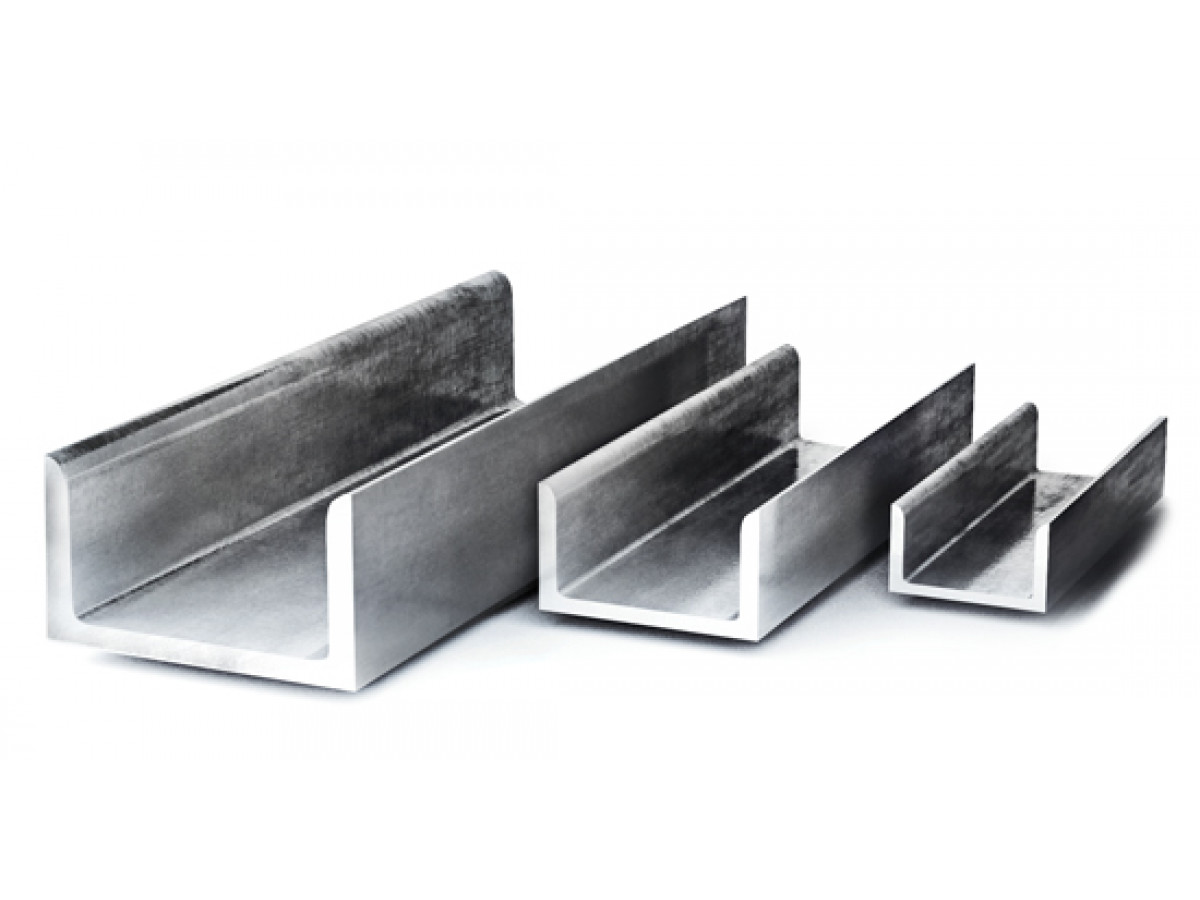

Channels mean one of the subspecies of rolled metal products manufactured by hot rolling. This is a steel part, which in cross section resembles the letter P, and is used in many manufacturing industries. Channels are presented in a wide range in several sizes. They are divided into categories based on weight, shelf thickness, degree of curvature, etc.

The site https://ukrstarline.ua/ru/nerzhaveyushchiy-metalloprokat presents all types of stainless steel, including various types of channels. To choose the right option, you need to figure out what types of channels are divided into and in what areas of work you cannot do without them.

Advantages and characteristics of channels

The main characteristic of channels is their high degree of strength and reliability. Due to the design features, such a small part is able to withstand high loads. It does not give in to deformation, withstands twisting, etc.

Products in the shape of the letter P today are presented in a wide range. Different types of channels differ from each other in the following characteristics:

- Size Indicates mainly the height of the part.

- Shelf width. It is regulated by the state standard, products are produced in normalized sizes.

- Angle value. It can reach up to 10%, in some details the faces can be strictly parallel to each other.

Among the main advantages, in addition to strength, one can indicate a long service life. The material from which the channel is made can withstand exposure to ultraviolet radiation, moisture, and chemical compounds . The part can last several decades.

What are channels

Manufacturers produce channels, marking them in different categories. It is by digital and letter designations that it is possible to figure out what technical characteristics the part has. Marking is carried out mainly in letters:

- U, if the edge of the product has a slope;

- P - the faces are completely parallel to each other;

- L - lightweight parts.

Manufacturers also use numbers for marking. The most common products go under indicators from 10 to 20. The larger the number indicated in the marking, the greater the strength of the channel. "Ten" is used mainly in mechanical engineering, and the part marked 20 is suitable for reinforcing bridges and reinforcing individual structures of a multi-storey building.

Where are channels used today?

The use of channels is not limited to any one industry. Depending on what load the product can withstand, it is used in the following industries:

- construction;

- machine building;

- building bridges and strengthening them.

At the same time, the detail was most widely used in the construction of buildings of various types. With its help it is possible:

- to give rigidity and guarantee better stability of individual elements and structures;

- put into production the parts necessary for the electrical network;

- install advertising banners on a reliable support;

- equip the roof of a country house;

- build bridges;

- strengthen individual elements of the building;

- carry out structural reinforcement.

Slightly less often, channels are used in the car building industry.

U-shaped metal products, made from rolled steel using hot or cold rolling, are distinguished by a wide range and the ability to withstand high loads. This makes the part universal and indispensable for a number of industries.