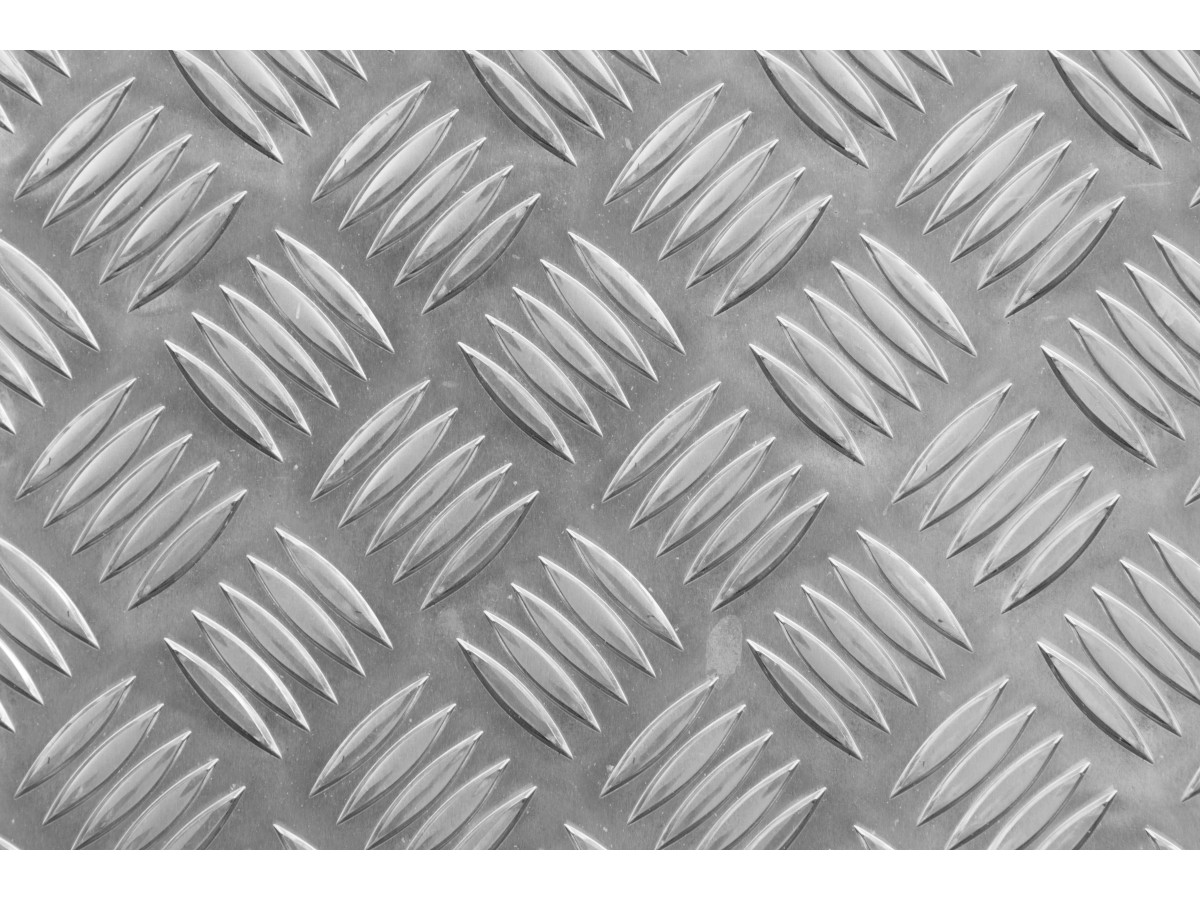

Corrugated steel sheets – is a type of rolled metal product that has a specific structure. Carbon steel was used in its production, and the hot or cold rolling method was used. On the one hand, there is a peculiar unevenness (ribbing), located at different angles in different sequences, differing in quantity and shape. We suggest that you consider this in more detail material, its varieties and operation.

Types of corrugated steel sheets

Corrugated steel sheets are divided into the following types:

- Type of corrugation: Steel sheet with a lentil pattern is considered the most popular option. On the surface there are oval elongated corrugations, shaped like grains of legumes. On the lentil form, the following patterns are basic: diamond (single arrangement), duet (pair arrangement), quintet and quartet (blocks of 5 and 4 pieces, respectively). On the surface of the corrugated steel sheet with a rhombic pattern, rhombuses of a three-dimensional shape and a depressed middle are formed. Due to this, adhesion to various surfaces is significantly improved. However, due to the accumulation of condensate in the concave part, the risk of corrosion increases, the weight of the structure increases. The slightest violation of the speed limit or technology at the intersection of the corrugation leads to a decrease in height.

- Size and thickness: The first indicator depends on the manufacturer. The thickness is usually 1.5-12 mm (choose based on your goals). Remember, the higher this criterion, the stronger and more reliable the material.

- Processing: Corrugated steel products have a special layer to protect against the negative impact of environmental factors, significantly extending their durability, ensuring resistance to moisture and corrosion.

Each type of corrugated steel sheet has its own unique qualities, making the material suitable for solving various problems. This product is the optimal choice for specific tasks, regardless of their complexity and operating conditions.

Advantages of Using Steel Corrugated Sheets Today

Corrugated steel sheets have positive characteristics, due to which they do not lose their popularity. The advantages include the following:

- Reliability: Corrugated sheets are made of high-strength steel, capable of withstanding significant loads and various mechanical damages, resistant to deformation, cracks and destruction.

- Slip Resistance: This material can be used in places where safety is a top priority. They are also suitable for use in warehouses, manufacturing facilities and other places as a slip-resistant coating.

- Anti-corrosion properties: Corrugated sheets are ideal for outdoor use due to their resistance to high humidity.

- Aesthetics: The material is optimal for decorative purposes, makes the appearance of products more modern and technological. It is also actively used in architecture, serves as cladding for the facades of structures and buildings.

Corrugated steel sheets are used in various industries due to their strength, practicality, durability, and reliability. They are resistant to negative environmental impacts and wear, and provide safe movement due to the corrugated surface.

How to choose the right corrugated steel sheet

To select the appropriate corrugated steel sheet, the following criteria must be taken into account:

- Purpose: These sheets with a diamond pattern of medium thickness are intended for construction and finishing works. Suitable for production processes and industrial tasks, give preference to thicker varieties.

- Usage: The material is optimal for rooms with high humidity, suitable for outdoor work. It is resistant to chemical influences, aggressive factors, is not afraid of fungus and mold, especially if covered with a protective layer of zinc.

- Dimensions: Standard parameters of such sheets are 1000-2000 mm, the shape is mainly square. Individual dimensions are possible if the product is needed to perform specific tasks and requirements.

Thanks to these factors, you will easily find a suitable option that meets all your wishes and requirements.

Conclusion

Corrugated steel castings guarantee the reliability and durability of manufactured products. They are completely safe, meet hygiene standards and quality standards, practical, durable, aesthetic, resistant to premature wear and tear and negative impact of environmental factors. When buying, it is worth considering their technical characteristics and purposes of use.