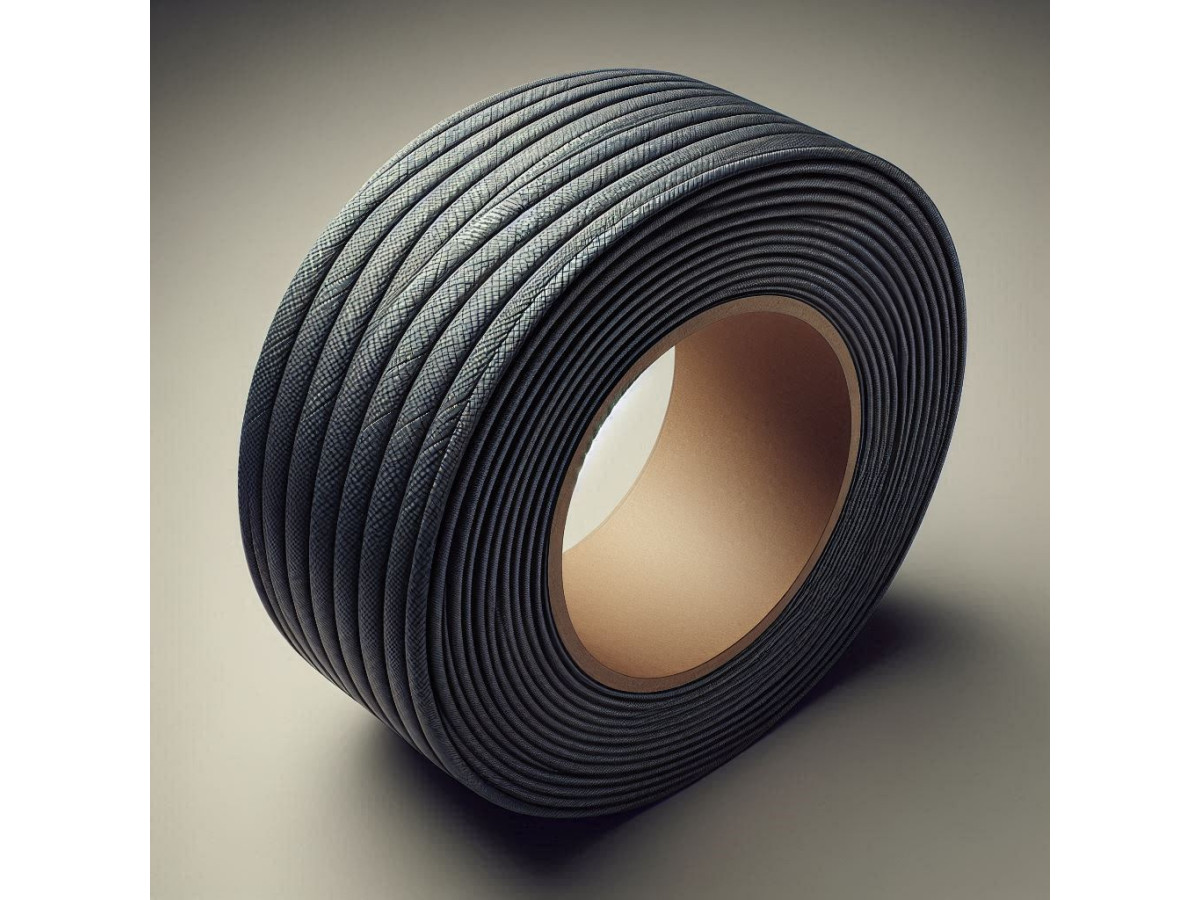

Gland packing – this is a high-quality sealant that ensures durable and reliable sealing of all connections. This product is actively used when joining parts of pumps, autoclaves, compressors, pipeline systems, etc. Below we will consider in detail the types of this material, its advantages and selection rules.

Types of gland packing

Gland packing is very popular due to its reliable sealing and durable connection of parts. This seal is divided into several types:

- Graphite: This gland packing has high heat conductivity, distributes it evenly over the entire area, due to which heat losses are reduced to zero. Creates a homogeneous mass, due to which leakage is prevented.

- Asbestos: This type is optimal for use in aggressive environments, has resistance to high pressure and temperature conditions. Due to various additional fillers and impregnations, products receive the necessary qualities, such as resistance to the negative impact of environmental factors and wear.

- Fluoroplastic: This gland packing provides maximum tightness when working with various substances (acid, water, steam, oil, gas). It can be used in high temperature conditions, as it does not conduct heat.

Due to the wide range of products, you can easily select the appropriate option that meets the specific tasks and goals set.

The benefits of using gland packings today

Gland packings have gained great popularity due to their outstanding advantages:

- Sealing: The material is an excellent sealant, capable of preventing leakage of various liquids and even gas. Serves as a gasket.

- Protection against contamination: The gland packing protects the devices from dust and moisture, thereby significantly extending their service life.

- Vibration noise absorption: The material absorbs sounds generated during equipment operation.

- Environmentally friendly: The filling does not emit toxins and does not contain any harmful components.

- Resistance to temperature changes: The gland packing can withstand sudden temperature fluctuations.

- Chemical resistance: The material is not afraid of alkalis, acids, aggressive environments, and can withstand chemical exposure.

- Thermal Resistance: The gland packing can work at high temperature while maintaining its original characteristics. It prevents the devices from overheating.

- Ease of use: The cord-like packing is easy to wind. It is also resistant to mechanical damage.

Due to its advantages, gland packing is used in various fields of activity. It is durable, reliable, strong, and is a high-quality material intended for sealing.

How to choose the right gland packing

To select gland packing, certain criteria should be taken into account:

- Material of manufacture: The gland packing must guarantee maximum tightness, be resistant to corrosion processes and extend the service life of the equipment.

- Standard: The material must meet the intended application. For example, if the equipment is used in an aggressive environment, the packing must be resistant to alkalis, acids and chemical solutions.

- Pressure temperature: This seal is resistant to sudden changes in temperature.

- Vibration resistance: Due to special additives, the packing absorbs vibrations and is wear-resistant.

- Budget: In some situations, it may be worth choosing a more expensive sealant that will provide reliability and efficiency.

- Reviews: Read reviews of each type of gland packing and choose the most suitable option.

- Manufacturer: Give preference to proven and reliable manufacturers with many positive reviews and a reliable rating.

Taking into account the factors described, you will be able to select the right gland packing that meets all requirements and wishes. It will ensure reliable operation of the devices and their tightness.

Conclusion

Gland packings are widely used in various industries. They are durable, practical, reliable, strong, resistant to chemical and mechanical impact, aggressive environments and premature wear. They are used as a sealant, providing the most effective sealing of joints, seams and connections. This material plays an important role in the operation of the equipment, is responsible for its tightness, serves as protection against the ingress of dirt, moisture and dust. You can choose a variety with the most suitable technical characteristics and performance properties.