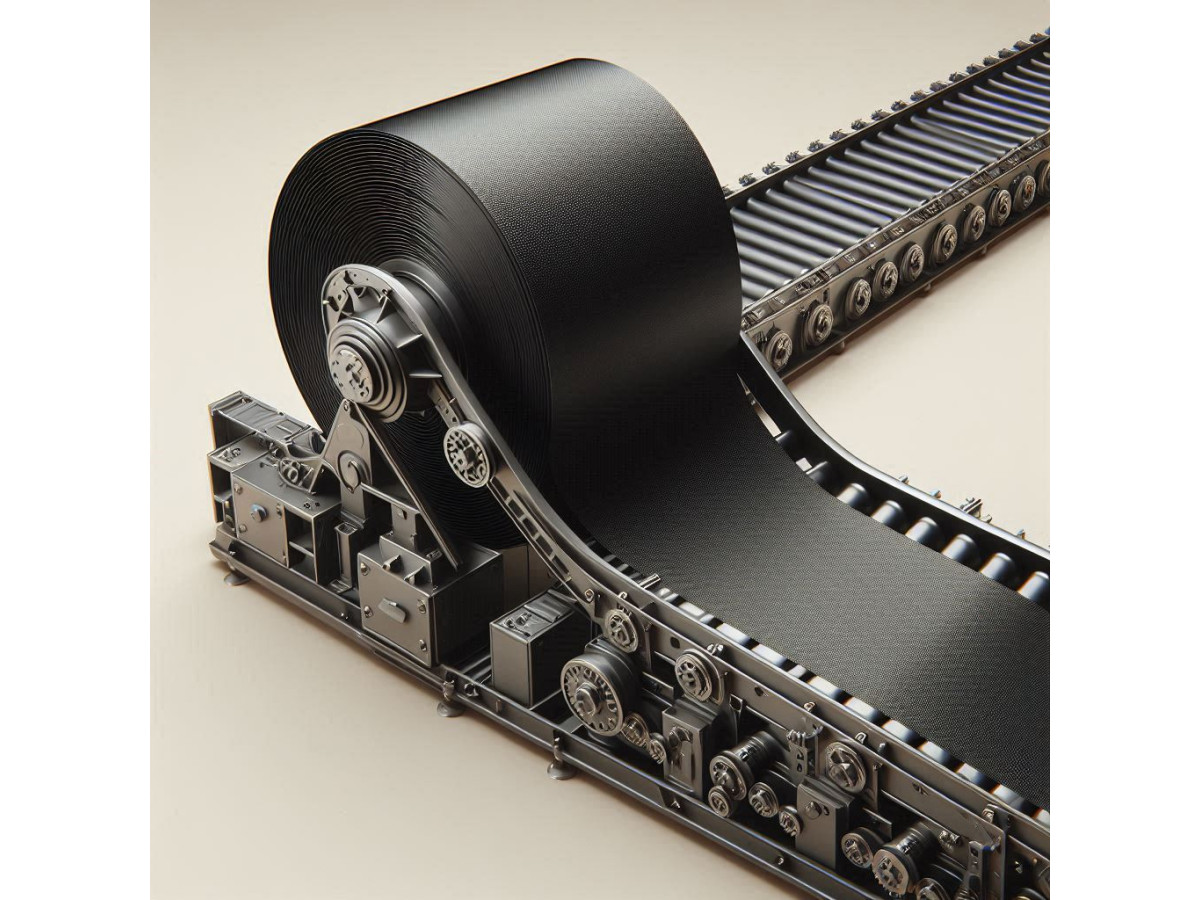

Conveyor belt – is a belt conveyor part, the purpose of which is to transport various products in an inclined, vertical or horizontal position. The product performs two basic functions: load-bearing and traction. Movement is carried out between production areas, ensuring stable and uniform transportation. We suggest that you familiarize yourself in detail with the advantages, types and selection of this element.

Types of conveyor belts

The conveyor belt is available in the following varieties:

- General Purpose: This belt is ideal for manufacturing processes that require the transportation of multiple items.

- Mine type: The conveyor belt is made of ordinary rubber and fabric, suitable for use in extreme conditions.

- Heat-resistant: This product is intended for metallurgy and is resistant to sudden temperature changes.

- Frost-resistant: The product can be used at temperatures down to -60 degrees, in heavy or medium duty conditions.

- Oil and petrol resistant: The material is resistant to various types of fuel and oils, suitable for use in chemical production, resistant to aggressive substances.

- Food: These tapes are used in the food industry and medicine, are completely safe for health, and can withstand temperatures up to +100 degrees.

- Modular: This type of conveyor belt can be embossed or flat, and is ideal for lifting and lowering goods in the presence of inclined areas.

Considering this range, you will be able to easily select a conveyor belt that meets all the tasks and goals set, and meets the necessary standards and requirements.

Advantages of using conveyor belt today

Conveyor belts are widely used in various industries. Such high popularity and demand is due to its following advantages:

- Increased productivity: The conveyor belt is designed to move large and heavy loads at high speed, thereby significantly increasing the efficiency and productivity of production processes.

- Safety: Conveyor belts eliminate the need for manual handling, thereby reducing the risk of injury to employees.

- Versatility: Belts are ideal for transporting various types of cargo, from bulk materials to individual items.

- Cost-effectiveness: The operation of the conveyor belt does not require large expenses.

- Continuity of processes: The conveyor belt ensures a continuous flow of materials, which speeds up production and completely eliminates downtime.

Conveyor belts are an ideal option for moving various goods, regardless of their weight, shape and size. They are resistant to wear and tear, negative impact of environmental factors, are reliable and durable.

How to Choose the Right Conveyor Belt

When selecting a conveyor belt, the following parameters must be taken into account:

- Design: The conveyor belt is capable of operating at high speed, quickly moving cargo, consumes a minimum amount of energy, and has a reliable and simple design, which guarantees a long service life.

- Coating type: The conveyor belt can be coated with polyurethane (optimal for chemical production), elastomer (wear-resistant material that can withstand heavy loads), silicone (neutral option, intended for the food industry), polyamide (elastic type, used in various industries), Teflon (distinguished by its resistance to high temperatures), polyvinyl chloride (flexible material, intended for construction work and more).

- Type: We have already talked about all types of conveyor belts, each has its own advantages and individual properties.

Thanks to the above criteria, you will select a conveyor belt that ensures efficient operation. The selected option will meet the necessary requirements and standards, meet quality standards, and be suitable for the implementation of specific goals and tasks.

Conclusion

Conveyor belts are gaining more and more popularity due to their outstanding characteristics: strength, durability, practicality, reliability, resistance to wear and tear and sudden temperature changes. This product is not afraid of aggressive substances and chemical influences, resistant to negative environmental factors. It is used in various industries, increases the productivity of processes.