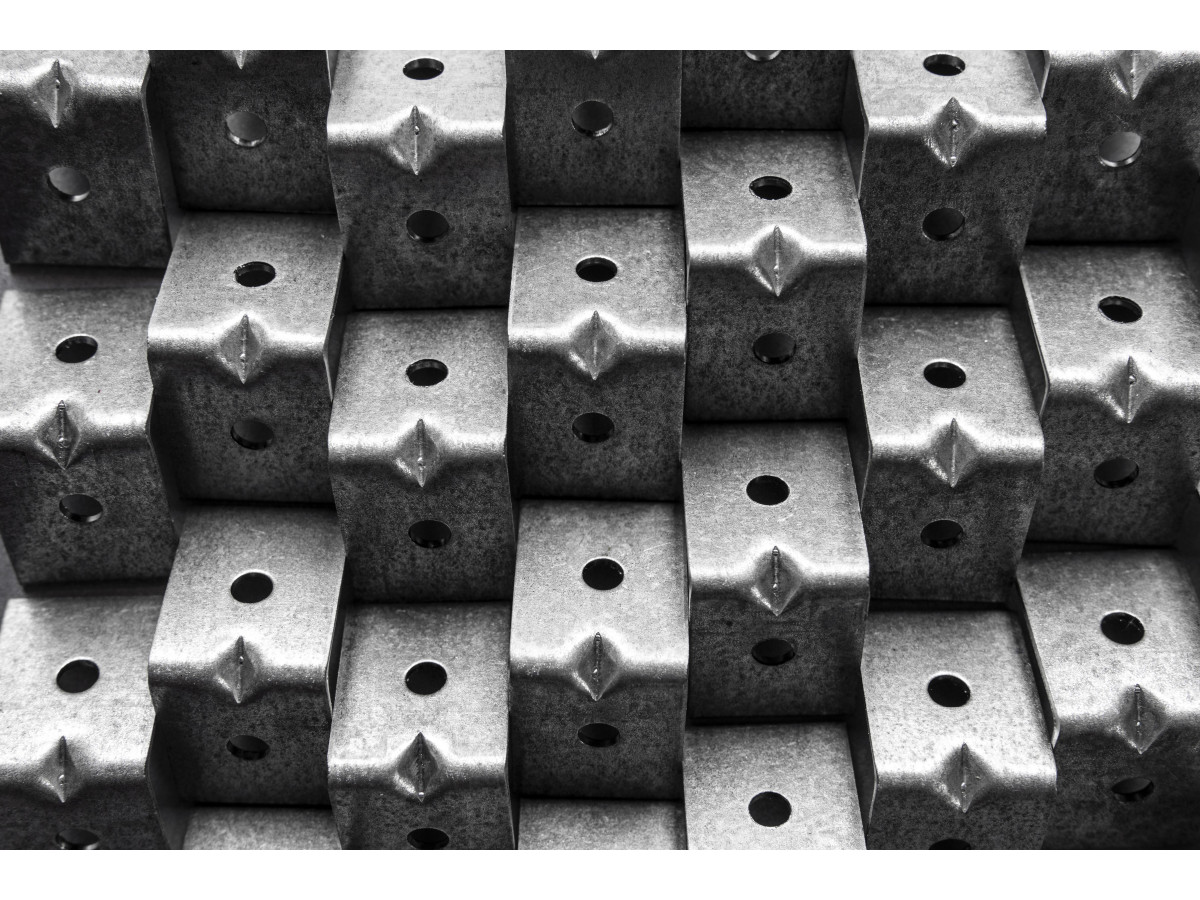

Babbitt alloy – is a special antifriction alloy consisting of lead, tin and other metals. This material is used in the manufacture of bearings, is characterized by increased resistance to corrosion processes and wear, is not afraid of moisture and mechanical impacttviya. Due to its hardness and plasticity, it ensures maximum efficiency of mechanisms, insignificant sliding and minimal wear of bearings. It offers to consider in more detail the advantages and varieties of this material.

Types of babbitt

The alloy is divided into three main types:

- Lead: The basic components of the alloy are a mixture of lead, tin, copper and other metals (depending on the grade of babbitt). The material tolerates high temperatures well, has low antifriction properties, and is optimal for bearings operating under low stress.

- Tin: This alloy is characterized by high strength, plasticity, wear resistance, anti-corrosion properties, increased friction coefficient, durability and reliability. Contains metals such as tin, nickel, copper, etc. This type is optimal for bearings subject to intensive loads.

- Calcium: This babbitt contains sodium, calcium, and lead. The alloy is quite cheap, has minimal heat conductivity, increased density, and is suitable for frequently replaced parts due to rapid wear.

You will easily select the most suitable type of babbitt, designed to perform various tasks, regardless of their complexity. The material is resistant to the negative impact of environmental factors, mechanical damage, aggressive environment, is not afraid of high humidity and corrosion.

Benefits of Using Babbitt Today

Due to various advantages, babbitt is gaining more and more popularity. The main advantages of this alloy are the following:

- Increased strength: Babbitt significantly extends the service life of bearings, serves as protection against corrosion and premature wear.

- Good thermal conductivity: Due to optimal heat dissipation, the bearings operate perfectly under increased loads.

- Minimum friction: The material reduces friction, improves the efficiency of the parts.

- Simple repair: When the mechanisms need repair, it is enough to replace the part of the babbitt that has become unusable.

This alloy is optimal for various mechanisms that operate under extreme conditions. Babbitt is resistant to corrosion, moisture, wear, durable, practical, and has a long service life..

How to choose the right babbitt alloy

Before purchasing this material, you need to pay attention to certain nuances of choice:

- Structure: The most common are tin babbitt and lead. The first is the most wear-resistant and quite durable, the second is not very durable, although it is cheaper.

- Manufacturer: Babbitt grades are designed for specific purposes and the surrounding atmosphere. The percentage of metals used affects the properties of bearings (durability, strength, reliability, wearability, etc.).

- Quality: Give preference to proven manufacturers who have documentation confirming the quality of the alloy, its ability to be used in various industrial sectors (most in demand in mechanical engineering).

- Form: The alloy is divided into three main types (ingots, rods, powder). When choosing, consider the mechanisms used and the purposes of use.

- Price: We recommend that you clarify the price of babbitt and the cost of delivery in advance, so that there are no surprises later.

Taking these factors into account, you will be able to select a babbitt that is optimal for performing tasks of any complexity. It guarantees reliable, uninterrupted and efficient operation of mechanisms

Conclusion

Babbitt is a fairly common alloy that has earned its popularity due to its outstanding features and qualities. It is resistant to aggressive factors, wear, corrosion, and temperature changes. It can withstand various types of loads (depending on the metals included in the composition), significantly extends the service life of parts, makes their replacement and repair less expensive and as fast as possible. The alloy is available in several varieties, which makes it possible to choose the most suitable option that meets your requirements, standards, and quality standards. You will definitely be satisfied with the characteristics of babbitt and its use.