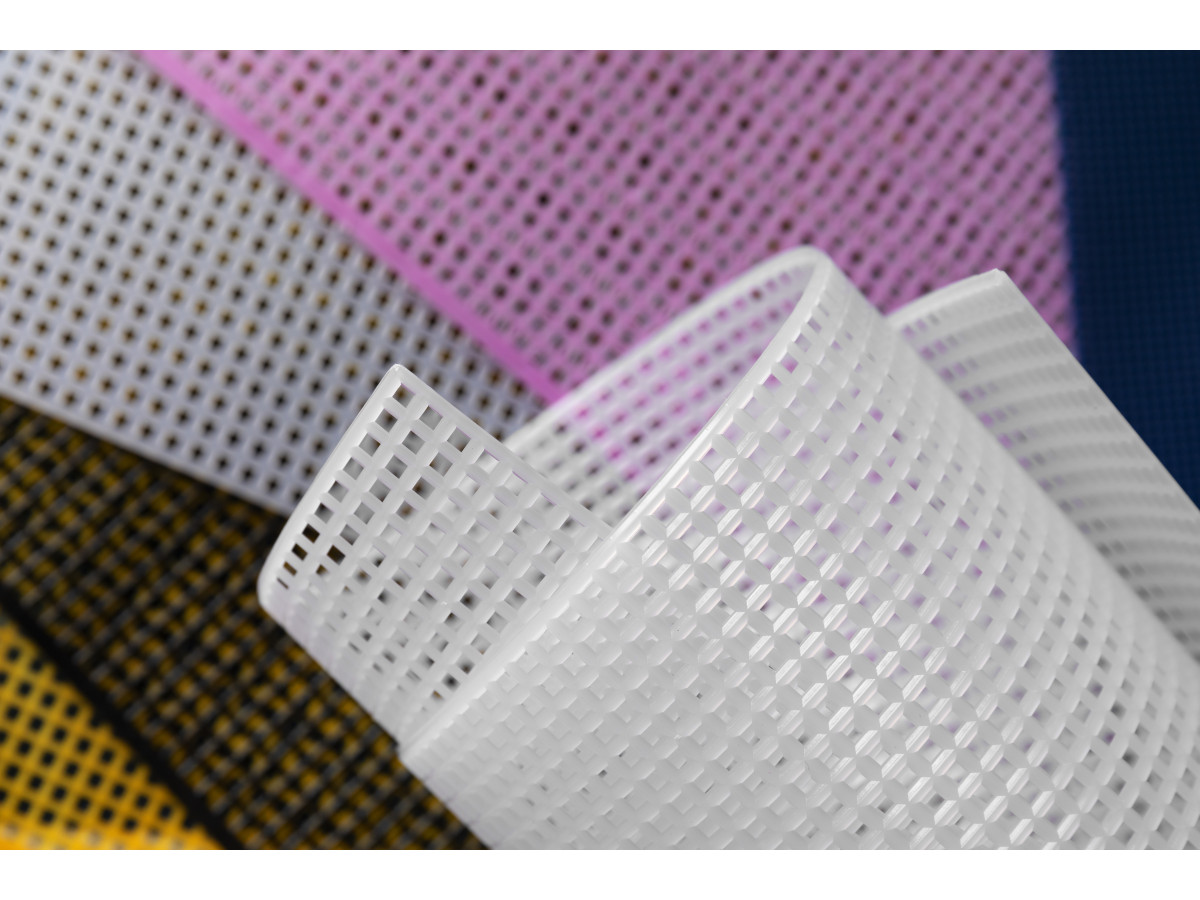

Glass fabric – is a material made by weaving glass and threads in a random order. It can be used as a textured reinforcement, in everyday production processes, and is suitable for the manufacture of special protective clothing used during firefighting. We suggest that you familiarize yourself in detail with the types, selection, and advantages of this fabric.

Types of fiberglass

Fiberglass is divided into several types, each with its own individual characteristics:

- Structural: This material is optimal for the production of mechanical elements and spare parts of machines, various equipment. The composition of such fiberglass is aluminum and boron, due to the carding, the fiber is strong, and has a low weight.

- Electrical insulating: The material is impregnated with a special mixture, can easily withstand high temperatures, is resistant to corrosion, and has dielectric properties.

- Fire-resistant: Basalt fiber was used in the production of fiberglass, providing resistance from -270 to +700 degrees, and characterized by minimal thermal conductivity.

- Roving: Glass fabric does not stretch, has antimagnetic properties, consists of twisted fibers and special threads.

- Radio engineering: Metal threads contained in the material reflect radio waves and solar rays.

- Construction: Glass fabric is used in the restoration of facades, the manufacture of wall reinforcements and reinforcement frames.

This range allows you to select fiberglass for specific purposes and tasks. Each type meets all necessary standards and norms, is high-quality, durable, practical and reliable.

Benefits of Using Fiberglass Today

It is not for nothing that fiberglass has earned such high popularity in industrial sectors, because it has the following advantages:

- Thermal conductivity: Glass fabric has the lowest coefficient, optimal for insulation of structures, industrial pipes and tools.

- Tear Strength: The material is resistant to stretching, superior to other types in this field.

- Anti-corrosion properties: Fiberglass is not subject to corrosion processes, ideal for use in extreme conditions, aggressive environments or high humidity.

- Light weight: The material does not cause any difficulties during installation or transportation.

- Plasticity: Due to its flexibility, the material is formed around any surfaces and objects. It can be cut, sewn, and is a universal option.

- Long service life: The material can withstand significant loads, mechanical damage and chemical exposure, is suitable for harsh conditions, and will last for several decades.

- Fire resistance: When exposed to high temperatures, an insulating layer is formed that prevents the spread of fire.

Based on the manufacturing processes and composition, the advantages of fiberglass may vary. The material meets all quality standards, sanitary norms, and is suitable for performing specific tasks and purposes.

How to choose the right fiberglass

To select the right fiberglass, there are certain factors to consider:

- Appearance: The material should not have any defects, be free of stains and streaks, and be of uniform color.

- Performance: Pay attention to resistance to aggressive environments. High-quality material is resistant to alkalis, acids, high humidity, and corrosion processes.

- Characteristics: Fiberglass must be as strong and durable as possible. The deformations and stretching, easily take their original shape.

- Purpose: Glass fabric is characterized by universal application, suitable for the production of various structures, electrical insulation, filtration, radio engineering purposes, construction work, etc.

These criteria allow you to select the appropriate fiberglass that meets your wishes and requirements. The range offers various varieties that are distinguished by excellent performance characteristics.

Conclusion

Glass fiber is a universal material suitable for any industrial sphere. It is resistant to wear and tear and negative impact of environmental factors, and can withstand high temperatures and high humidity. It has a long service life, is practical, reliable, durable, and resistant to chemical and mechanical impact. Having tested the material once, the choice will fall on it in the future, because it is not afraid of difficulties regarding operation and aggressive environmental factors.