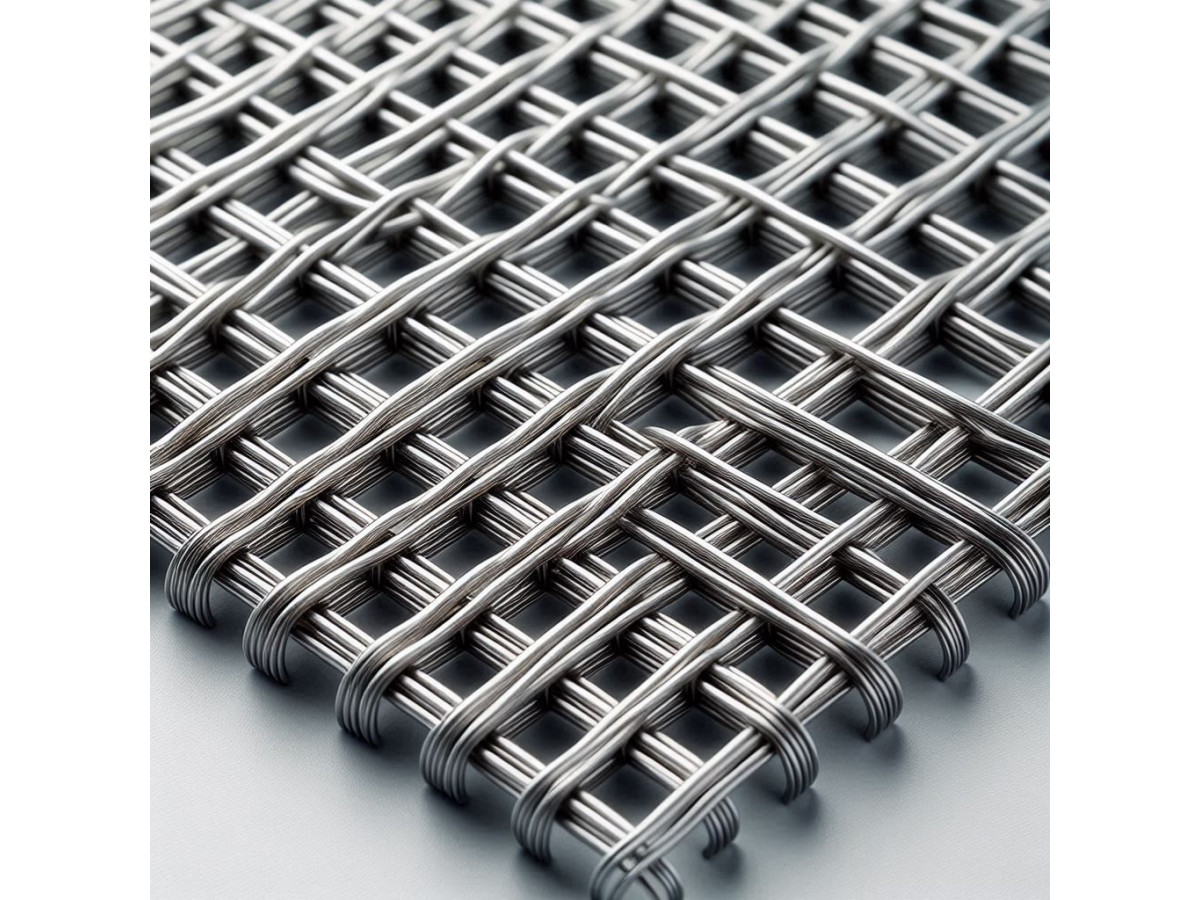

Woven stainless steel meshes are an indispensable material in many industries and construction sectors. Despite their high resistance to corrosion and mechanical damage, these products require proper maintenance to ensure a long service life and maintain their technical characteristics. Let’s examine the main aspects of caring for woven stainless steel meshes and methods to extend their operational period.

Material Characteristics

First of all, it is important to understand that even the term "stainless" does not mean complete immunity to corrosion. Improper use or lack of proper care can expose the mesh to various types of damage. This is particularly true for products operating in aggressive environments or at high temperatures.

The main enemy of woven stainless steel meshes is contamination. Particles of dust, oil, industrial waste, and other pollutants can gradually accumulate in the mesh cells, reducing its permeability and creating conditions for the development of corrosion processes. Therefore, regular cleaning is the first and most crucial step in maintenance.

Cleaning Methods for Woven Stainless Steel Meshes

Here are the main methods for cleaning woven stainless steel meshes:

- Mechanical cleaning with soft-bristle brushes - suitable for removing surface contaminants, dust, and light deposits. Brushes do not damage the structure of the mesh.

- High-pressure water washing - an effective method for removing more stubborn contaminants. The pressure of the water jet allows for cleaning hard-to-reach areas.

- Ultrasonic cleaning - based on the action of ultrasonic waves that create cavitation, breaking down contaminants at the molecular level. This method is suitable for delicate cleaning and removing fine particles.

- Chemical cleaning with special compositions - used for removing complex contaminants such as fats, oils, and organic compounds. The choice of composition depends on the type of contamination and the mesh material.

- Steam treatment - used for removing organic contaminants, disinfecting, and sterilizing. Steam effectively penetrates the mesh structure and softens contaminants.

- Blowing with compressed air - used for removing dry dust and small particles from the surface of the mesh. This method is fast and effective.

- Vacuum cleaning - allows for the removal of the smallest particles and contaminants from the pores and micro-cracks of the mesh. This method is applied in high vacuum conditions.

- Combined cleaning methods - a combination of several methods allows for achieving the best cleaning results depending on specific conditions.

When selecting a cleaning method, it is essential to consider the type of contamination, the size of the mesh cells, and the operating conditions. For example, for fine filter meshes, mechanical cleaning with brushes may be unacceptable due to the risk of damaging the weaving structure.

Particular attention should be paid to chemical cleaning. Despite the resistance of stainless steel to most chemicals, some aggressive compositions can damage the protective oxide layer. Therefore, before using any chemical cleaners, it is necessary to check their compatibility with the mesh material.

Storage Rules for the Material

An important aspect of maintenance is the proper storage of unused meshes. To prevent deformation and damage, the following rules should be followed:

- Avoid damp rooms, as moisture promotes the development of corrosion and mold. Optimal storage conditions provide minimal changes in air humidity.

- Direct contact with the floor can lead to mechanical damage, contamination, and hinder air circulation.

- Using shelves or stands ensures free air circulation around the mesh, preventing condensation and protecting against mechanical damage.

- Ultraviolet radiation can cause fading and deterioration of the mesh material. Store meshes in a dark or dimly lit place.

- Contact with acids, alkalis, and other aggressive substances can lead to corrosion and damage to the mesh structure.

- Good ventilation helps remove moisture and prevents condensation.

- Storing in an unfolded state prevents creasing and bending, while loose winding prevents deformation.

- Regular inspections allow for the timely detection and elimination of possible damage.

Periodic inspection of meshes is an important part of the maintenance program. This allows for identifying early signs of wear or damage and taking timely measures to address them. During inspections, special attention should be paid to the integrity of the weaving, the presence of deformations, signs of corrosion, and the quality of welds, if any.