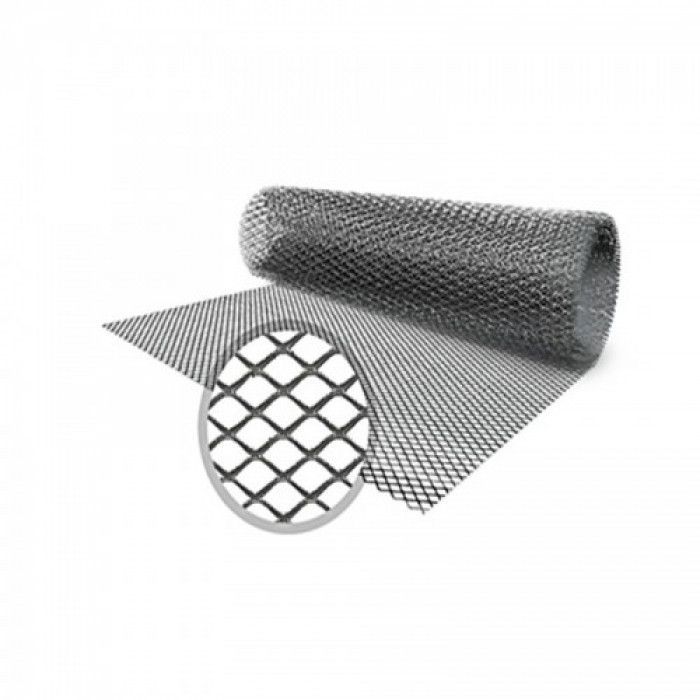

Galvanized expanded metal mesh 15*30 (5 sq.m.) has a specific seamless manufacturing technology, namely: sheet metal is uniformly cut and stretched to obtain symmetrical cells. The end result gives us a durable, lightweight, multifunctional material. The all-metal base guarantees that the mesh will not unravel or lose its shape.

The scope of this material is very extensive, consider the most common options:

reinforcing plaster layer

production of decks and stairs

finishing of ventilation gratings, radiators, fireplaces, car tuning

screening of various materials

construction of household and commercial fences

construction of enclosures for animals

production of various decorative elements

Galvanized expanded metal mesh has special characteristics. Made of zinc-coated sheet, it is protected from corrosion processes, which means it has a longer service life and retains its spectacular appearance longer. Light in weight, the mesh perfectly adheres to work surfaces, and is also able to withstand severe mechanical stress. This is a fairly flexible material that easily takes the required shape, and fire resistance allows you to expand the range of its use.

TsPVS is a standard expanded metal sheet manufactured in accordance with GOST 8706, which is first evenly cut through and then stretched into cells arranged in a checkerboard pattern. The cells are diamond-shaped.

increasing impact resistance and other mechanical characteristics of the reinforced surface;

protection of the plastered surface from gaps and cracks of various sizes, which arise due to the poor quality of building mixtures, all kinds of mechanical influences, fluctuations in humidity and temperature.

Stainless and conventional TsPVS is perfectly combined with any waterproofing, putty and plaster compositions, guaranteeing a durable and truly durable coating. The described grids can be used in all climatic zones. Stainless TsPVS is not afraid of alkaline aggressive compounds, does not lose its properties in humid environments.

Subtleties of production and dimensions of TsPVS

The described material is produced on press machines. The raw material for the manufacture of mesh for fences and reinforcement is rolled products in sheets that meet the requirements of GOST 8706. It is allowed to use steel sheets up to 6 mm thick (minimum 0.5 mm).

There is also an aluminum mesh, which, as you know, is produced from rolled aluminum up to 8 mm thick. The scope of the latter is quite limited. Typically, aluminum products are used to strengthen the strength of facade panels and create decorative building structures.

All-metal expanded metal mesh is produced by the method of simultaneous cutting and drawing of steel (aluminum) rolled products. This technology causes the complete absence of wicker or welded joints in finished products. The final indicator of material stiffness depends on the step with which the rolled metal is fed into the press machine, and on the thickness of the sheets used.

The geometric dimensions of the grids vary widely. The cells can have a width of 3 to 50 mm, a height of 1 to 25 mm, and a bridge thickness of 0.5–8 mm. The length of the mesh is not limited by any GOST or technical conditions that are accepted at the plants that produce such products. The main thing is that its length is convenient for operation and does not cause problems during transportation from the factory to the user.

Galvanized mesh is made from sheets coated with a zinc layer (its thickness is indicated in GOST). Enterprises also manufacture CPVS from cold-rolled steel (stainless steel and carbon steel). There are also nets with a special protective and decorative layer. The most popular is galvanized stainless products. But products with a decorative surface are still rarely used.

How do manufacturers ensure the quality of designs?

The high performance of PVA meshes depends on the quality of the feedstock for their manufacture. Expanded aluminum and steel sheets must comply in all respects with GOST 8706. In addition, finished products undergo a number of checks. Their geometric parameters are analyzed with a caliper according to State Standard 166 or a special (according to GOST 750) tape measure.

Reinforcement meshes are checked visually for the quality and thickness of the zinc layer, for the absence of cracks, notches, burrs and flaws on their surface. Different enterprises adopt their own specifications, according to which the quality of the finished product is analyzed. The analysis is carried out by a tool that guarantees the required accuracy of measuring the shape and parameters of the cells.

Mesh is supplied in bundles or in rolls. Packages are sheets of finished products arranged horizontally. Rolls can include from 1 to 4 products. The specified container must be tied with a tape for packaging according to the standardmouth 3560 to ensure the safety of products during transportation. It is necessary to store the material in rooms where there are no fumes of aggressive chemical compounds.

Advantages of galvanized mesh TsPVS:

light weight;

the mesh has a transparent structure for plaster, which allows it to transmit light and sound well;

high flexibility allows the mesh to take any shape;

damage to any element does not lead to the destruction of the entire mesh;

good grip provides a three-dimensional structure;

mesh has high mechanical strength;

mesh can be subjected to electric welding, easy to cut;

does not corrode;

it is resistant to temperature extremes, burning, high levels of humidity;

ease of installation;

long-term operation;

an interesting, original design that attracts attention, like the look of the Manye (hexagonal grid);

the integrity of the structure;

lower cost compared to other types of mesh materials.

It is a wide range of advantages that makes the CPV grid in demand.

You can buy from us Galvanized expanded metal mesh 15*30 (5 sq.m.) at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.