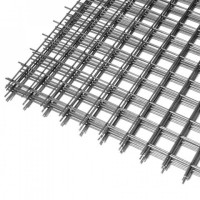

Galvanized masonry mesh 50x50x4 mm is a material widely used in construction. It serves as a reinforcing element in the construction of brick walls, laying road surfaces, as a frame for greenhouses, greenhouses, cages and animal pens. Masonry reinforcing mesh is produced by the method of spot welding of cross-shaped joints of reinforcing bar KhDAP (cold-formed reinforcing bars) of class B500C and VR wire.

It is advisable to use reinforcing mesh for the construction of arches, terraces, various types of fences.

Galvanized masonry mesh is widely used in construction and finishing works:

for reinforcing prefabricated and monolithic reinforced concrete structures and products;

to strengthen residential buildings, commercial buildings, industrial complexes;

for reinforcing brickwork;

for reinforcement when pouring floors, ceilings, foundations;

for plastering works, when carrying out finishing works, for leveling vertical and horizontal surfaces;

for the separation of building bulk materials;

in the construction of paths and curbs;

for decorative surface finishing;

to create generic markup.

In addition, galvanized masonry mesh can be used (and is used) in other areas of activity:

in the construction of fences and fences; welded galvanized mesh for fences is a standard solution for private areas;

when assembling cages and pens for animals and birds;

as a support for plants and flowers;

as a base for an arch or pergola.

Advantages

The term "galvanized" mesh is commonly understood as two modifications of materials:

canvases made of galvanized wire subjected to welding;

products from low-carbon wire, which is subjected to welding, and only then galvanizing, which is carried out by galvanic and hot methods.

The second variety is considered the most "resistant" to the formation of rust.

The masonry mesh has a low weight, ease of installation, affordable cost.

Masonry mesh with zinc coating of both types has a wide range of additional advantages, which contribute to the active use of materials in various fields of activity. Among the most important advantages for buyers are (in comparison with non-galvanized products):

increased resistance to corrosion, high humidity, alkalis;

more attractive appearance.

It should be remembered that the term "galvanized" can also mean various types of meshes, in particular, all-metal expanded metal, chain-link (wicker) and woven.

Specifications, features

The technical requirements that the masonry mesh must comply with are specified in GOST 23279-85 “Welded reinforcing meshes for reinforced concrete structures and products. General technical conditions". It is made from reinforcing wire of classes Bp-I and B-I in accordance with GOST 6727-80.

Distinctive characteristics of galvanized masonry mesh:

the smaller the mesh size, the stronger the mesh, and the higher its ability to withstand heavy loads;

the weight of the masonry mesh affects its strength: the greater the weight, the greater the load the mesh can withstand.

The strength of the mesh can be determined by its weight: you need to weigh a roll of masonry mesh, calculate the weight of 1 sq. m. and compare with the theoretical (reference) weight. If the difference in weight is more than 5%, then the remaining parameters should be carefully checked.

An interesting alternative to welded mesh is Magnier (hexagonal).

Symbol, marking

Marking is an obligatory element of mesh materials packaging. The symbol on the package provides the buyer with the following information:

name or trademark of the manufacturer;

conditional designation of grids;

the number of grids in the package;

mass of a package or a roll, t;

batch number and date of manufacture.

It is also possible to meet masonry mesh markings, which include cell dimensions, wire diameter in millimeters, product dimensions (card or roll) in meters.

For example, marking 50x50x2 (1.5x45) means that the welded galvanized mesh has a cell of 50x50 mm, wire with a diameter of 2 mm, roll width - 1.5 m, length - 45.

Manufacturing process

A galvanized masonry mesh is formed from wires located in 2 mutually perpendicular directions. In places of their intersection, they are welded by resistance spot welding. They are made in the form of rolls and cards.

Zinc is applied to the mesh by a method called "galvanizing" - this is an electrochemical process (electrolysis) that takes place in a special drum. The hot-dip galvanizing method is less commonly used, as it is expensive. Thanks to galvanizing, the mesh without additional processing gets a perfect appearance, which has a positive effect on its properties.

The video below explains the difference between welding before and after galvanizing.

The coating must comply with GOST 9.301-86 "Unifiedcorrosion and aging protection system. Metallic and non-metallic inorganic coatings. General requirements". According to this standard, a zinc coating with a thickness of 8-9 microns will be applied to the masonry mesh. The strength of such a coating is confirmed by the fact that the grid during testing can be in salt fog for 150 hours without damage.

Types and sizes

The industry produces a fairly extensive range of masonry mesh. To separate the entire range of products, several criteria are used: the form of release, the size of the cells and the diameter of the wire used.

in rolls

There are two forms of mesh production, including masonry galvanized. Roll materials are in higher demand. This is due to the fact that the rolls of masonry (welded) galvanized mesh are large, which saves time and fasteners for fixing materials to each other. As for the size of the rolls, there are a huge number of options, both in width and length. In construction, canvases measuring 500 by 2000 mm are especially popular. In addition, products in rolls are more convenient to mount, both for their intended purpose, and, for example, in the construction of fences and barriers.

Light and flexible products with a wire diameter of 3 to 6 mm are wrapped in rolls. The grid of this form of release is used:

in brickwork, to increase the strength of walls, prevent cracks, increase adhesion of masonry and cement mortar;

for reinforcing the pavement in order to prevent mixing of layers and increase strength;

for the construction of fences and pens;

when carrying out plastering works in order to increase the adhesion of finishing materials to the surface of the walls, it prevents the formation of cracks;

for reinforcing foundations in low-rise construction, which significantly increases the strength of foundations and floors.

The mesh in the cards is more rigid and durable; it is used for reinforcing surfaces in construction. The resistance to loads of brick and concrete floors is achieved due to the uniform distribution of the load. It is the masonry mesh that acts as a skeleton, ensuring the resistance of the structure to variable and significant loads.

Products in the cards are used at different stages of construction. It is used to reinforce aerated concrete blocks and bricks, when facing surfaces, when laying tiles and tiles, leveling walls, to reduce the impact of deformation processes that occur during temperature and humidity changes, and the impact of loads. In addition, the grid in the maps is excellent and is successfully used in the construction of the frame of greenhouses.

The sizes of the maps also vary widely. Familiarization with the range of manufacturers and suppliers demonstrates the variety of offers, which provides any customer with the best solution.

Other

The size of the cells determines the scope of the materials. The lower this indicator, the greater the strength of the canvas. Manufacturers offer products with cells from 30 to 500 mm. Also, enterprises producing mesh have the opportunity to manufacture a product with non-standard sizes. Despite the existing variety, 50x50 grids are popular; 50x100 and 100x100. The first type of products is used to strengthen the masonry of various types.

For the manufacture of masonry galvanized mesh, a wire with a diameter of 2.5 to 5 mm is used. The thicker the wire, the greater the load the canvas can withstand, the correspondingly higher the price of the product. The mesh wire diameter should be selected based on the thickness of the cement mortar or plaster layer.

You can buy galvanized masonry mesh 50x50x4 mm from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.