Welded galvanized mesh 25 х 12 мм Ø пров. 1,8 мм is a very important and useful material in the economy, animal husbandry, poultry farming, construction and many other areas. Welded galvanized mesh is produced by welding at the intersection of longitudinal wires (they are called warp wires) and transverse wires (weft wires), the wires in the galvanized welded mesh intersect at right angles, which forms square and rectangular cells. The production of welded galvanized mesh is divided into two main methods: - welding of black wire, after which the mesh is galvanized by immersion in molten zinc. This method improves the quality of the welded mesh, its service life, corrosion resistance and gives a more aesthetic appearance; - welding of pre-galvanized wire, in this way the welded mesh is cheaper, due to the smaller amount of zinc used, however, spots are formed at the welding points, which, subsequently, can lead to corrosion of the mesh in this place.

Welded galvanized mesh, also known as masonry or plaster mesh, has high strength, elasticity and low weight, resistance to deformation and corrosion, which makes it a popular hardware in the field of construction, reinforcement, finishing works, and is also used as a barrier.

Galvanized welded mesh is in demand among various industries for a reason. Galvanized steel mesh has a whole range of useful characteristics, which makes it an almost indispensable material. Galvanized welded mesh is characterized by: good corrosion resistance, deformation resistance, rigidity, wear resistance, relatively low price, ease of installation and use, high service life.

Galvanized welded mesh is made of wires arranged perpendicular to one another. In places of intersection, the wires are interconnected by spot welding.

It differs from uncoated analogues in greater resistance to negative environmental influences, as a result of which the service life of the product increases (moreover, the service life of a welded galvanized mesh is much higher, but the price does not differ much from the price of a welded mesh that is not covered with a protective layer).

There are two methods for joining galvanized welded mesh:

Welding wires, then galvanizing the finished mesh. Advantage: the joints are coated with a protective layer.

Galvanizing wires, then welding them into a solid mesh. Advantage: zinc coating is more evenly distributed over the surface of the product; less zinc is consumed in the manufacture of the mesh, which reduces the cost of production.

Galvanization of the product can also be done in two ways:

Hot galvanized. The wire is passed through molten zinc, eventually forming a thick protective layer on it. On labels for the finished product, this method is denoted by the terms “hot dip” or “hot dipped”.

Galvanizing by galvanic (electrolytic) method. Used to obtain thin coatings. It is indicated on the label with the word "elektro".

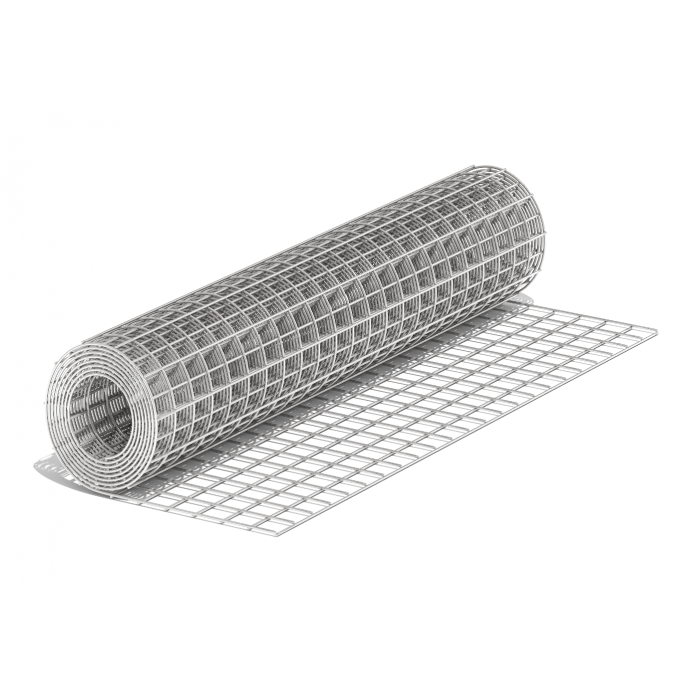

galvanized welded mesh in coils

Different types of grids differ from each other in the following parameters:

Cell size. The distance between adjacent warp wires (longitudinal wires) or weft wires (transverse wires) is taken as the cell size of a galvanized welded mesh. The vast majority of products have square-shaped cells, but there are also rectangular counterparts.

The thickness of the wire from which the mesh is made.

The thickness of the protective layer. The labels indicate the amount of zinc applied per unit surface of the wire. The more zinc, the thicker the protective coating, therefore, the mesh will last longer. As the quality increases, so does the price. The cheapest products have the thinnest protective coating and are the least durable.

The galvanized mesh varies according to the type of configuration:

Welded galvanized mesh in cards

galvanized welded wire mesh in rolls

Welded galvanized sheet can be obtained in two ways.

Galvanized wire is located perpendicular to each other, welding is carried out. This technology does not provide the highest level of corrosion resistance, since the welded joints are not additionally processed and there is a (albeit small) probability of corrosion. But there is also a positive point - in the manufacture of canvases, a smaller amount of zinc is consumed, which allows saving on production.

The low carbon wire is placed perpendicular to each other and spot welded. The finished sheet is galvanized, the welding joints are “fixed” with a coating, which prevents corrosion.

Galvanizing is done in two ways. The first of them is hot galvanizing, the process of which includes several stages, the material is cleaned, degreased, pickled, washed, dried and then passed through molten zinc. Coatingperformed on a special processing line. The disadvantages of the technology are the high cost and unevenness of the resulting zinc layer.

Coating by means of galvanization technology allows to obtain a monolithic and homogeneous, but thin coating. An important advantage of the technology is the complete absence of the risk of peeling the coating. This efficient and inexpensive method is most popular when working with meshes.

Welded galvanized mesh is used primarily for the construction of barrier structures. Fences are suitable for fencing construction sites, sports fields and stadiums, summer cottages, industrial buildings, warehouses, industrial buildings, commercial areas, etc. Gabions serve as an interesting solution for the design of private and public spaces.

Galvanized welded mesh gabion.

Often used in construction:

When pouring the floor. The preparation of the rough and finish base requires a reinforcement procedure, where mesh materials are an inexpensive, reliable and durable solution.

Underfloor heating equipment. In this case, the mesh acts not only to strengthen the coating, but also to fix the pipe to the floor.

When laying bricks and blocks, a special grid is used - galvanized masonry. The construction of one-story buildings involves strengthening the structure. Masters perform reinforcement of every fourth row.

During the formation of the armored belt. The construction of buildings with more than one floor, the floors of which are made of reinforced concrete slabs, requires the use of an armored belt. The mesh is an excellent alternative to reinforcement, which in the process of work will need to be connected, forming a frame. It is easier and faster to work with the mesh, it is suitable for reinforcing floors, the construction of which is carried out using cement mortar and glue.

Performing plaster work. The materials are used when carrying out work inside and outside, suitable for reinforcing coatings of various thicknesses, but not more than 50 mm.

Strengthening the foundations. The use of mesh helps to protect objects from cracking and unwanted deformations, and provides resistance to moisture and temperature extremes.

Road construction. The use of welded products allows to increase the strength of the roadway and increase its service life. Also, the grid acts as the basis for laying paving slabs, concreting entrances.

Agriculture is another industry where galvanized welded mesh has been successfully applied. Here the mesh is used in the manufacture of cages, the construction of pens and aviaries.

In addition, coated materials are successfully used for:

production of various frameworks;

pipeline sheathing;

protection against rodents: mice and moles;

manufacture of mice and rat traps;

obstruction of ventilation openings;

production of feeders for fishing and much more.

In these fields of activity, not only welded mesh is used, but other types of zinc-coated materials: TsPVS, chain-link, woven, as well as various types of Manye (hexagonal cloths).

You can buy from us Galvanized welded mesh 25 х 12 мм Ø пров. 1,8 мм at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.