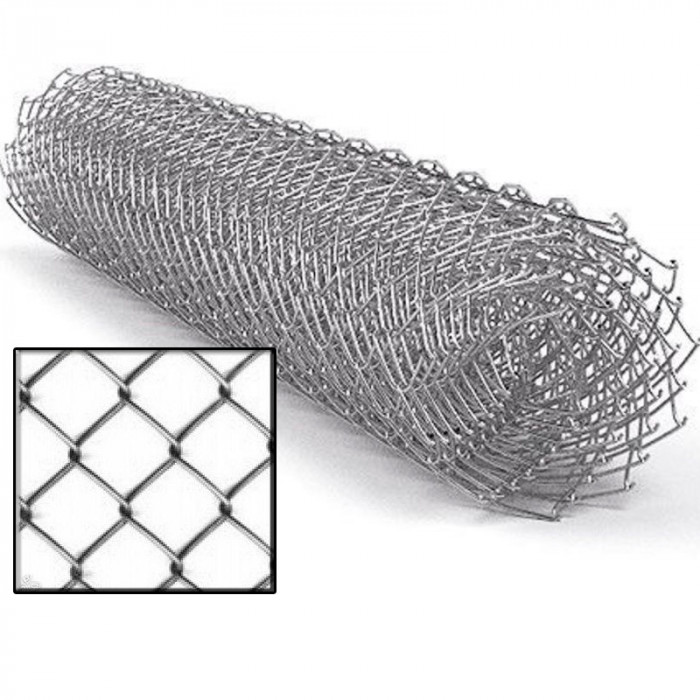

Mesh netting galvanized mesh 60x60 mm is a metal mesh woven using a special technology (a flat wire spiral is screwed into one another) using a mesh weaving machine. Named after the German Karl Rabitz, who invented and patented the netting machine at the end of the 19th century.

Scope of chain-link:

territory fencing

strengthening of land slopes, strengthening of mine workings;

production of enclosures for animals and birds;

fencing of sports complexes (for example, tennis courts);

screening of loose materials;

fastening of heat-insulating materials;

as a basis for plaster (reinforced mesh).

The size of the mesh cells of the chain-link is determined by the distance between the opposite sides of the rhombus, which is called the gap. You can buy a chain-link mesh with a mesh size of 5 to 100 mm.

It should be noted that GOST regulates the diameter of the wire from which the mesh is made with a certain cell size. For example, a mesh with a cell size of 10x10 can be made from wire with a diameter of 1.4-1.6 mm. As the lumen of the cell increases, the diameter of the wire used for its production increases.

The chain-link mesh is used for: fencing, screening sand, clay and other bulk materials, making cages, enclosures for dogs in the house and animals in the zoo, reinforcing the plaster layer, fencing rotating parts, blocking ventilation holes, wrapping poles to prevent sticking ads, making containers for storage.

The mesh of this type is made both on a simple machine by screwing one into the other wire spirals with a flat coil, wound directly on the working body of the machine, and on high-performance semi-automatic mesh weaving machines, mainly of German manufacture.

The raw material for the manufacture of the chain-link mesh is low-carbon steel wire. Along with steel wire without anti-corrosion coating, polymer-coated and galvanized wire is used. It is extremely rare that the chain-link mesh is made of stainless and aluminum wire.

The chain-link mesh is used to create fences, sifting bulk materials, fastening mine workings in mines and mines, when performing heat-insulating, plastering works, cages and enclosures for animals are made from it.

The chain-link mesh is subdivided according to the shape of the cells into a woven rhombic mesh (the acute angle of the rhombus is about 60 °) and a woven square mesh.

The grid the Chain-link is delivered in rolls. As a rule, the height of the roll is 1.5 m, and the length of the roll is 10 m. But you can order from the manufacturer a mesh width from 1 to 4 m, manufacturers usually make the mesh length up to 18 m. When producing mesh on manual or simple machines, as a rule, the ends of the spirals do not bend. In the production on mesh machines, in most cases, the ends of the spirals in rolls are bent, connecting with each other.

Chain-link mesh can be supplied in ordinary rolls, when the mesh web is wound in the usual way (this option is convenient when installing the mesh), and in compact rolls, when the spirals come into close contact when winding, and as a result, the mesh roll has a smaller diameter with the same length. The ends of the mesh rolls are wrapped with thick paper, burlap, artificial fabric or polyethylene film.

The chain-link mesh is used mainly for fencing areas and is not protected from rain and toxic gases. Therefore, if the chain-link mesh is not protected from moisture, then after the first rain it will begin to rust. The chain-link mesh is protected from corrosion in several ways: by painting, galvanizing and using a polymer coating. The most common way to protect the chain-link mesh from corrosion is galvanizing. Most "coated" chain link meshes are made from galvanized steel wire. Therefore, the amount of zinc on the galvanized wire is very important. Most factories in the CIS cover the wire with zinc using the hot-dip galvanizing method. With this method, the zinc content on the wire ranges from 70 to 90 g/m2. The chain-link mesh made of such wire will not rust for 20-25 years. Recently, in order to reduce the cost of production, in Russia they began to master the coating of wire by the electrolytic method. In this case, it is possible to obtain about 10 g/m2 of zinc on the wire, which is very small, but at the same time sufficient to call the grid galvanized. A mesh made of such wire may begin to rust within a year or two after the start of operation.

But even a large amount of zinc on the chain-link grid does not save from corrosion if the chain-link grid is operated on the coast of the salty sea. In such terrain, it is recommended to use a chain-link mesh made of steel wire coated with a polymer coating. A poor-quality polymer coating tends to fade in the sun (discolors) and crack in the cold. But the best manufacturers use a polymer coating that does not fade in the sun and can withstand up to 35 degrees below zero. In order to determine the quality of the polymer-coated chain-link mesh, you need tolook at the inner surface of the spiral from which the mesh is made. If there are scratches or cuts in the polymer coating in this place, this means that the mesh is of poor quality (moisture gets into the cuts and the mesh quickly rusts under the polymer coating) and, most likely, in a year or two the polymer coating will burst in the cold and fade in the sun.

The strength of the chain-link mesh directly depends on the size of the mesh and the diameter of the wire. The smaller the cell and the larger the diameter of the wire (the more metal per square meter of mesh), the stronger the woven mesh. Since the price of the Rabitz mesh is based on the cost of the wire, some manufacturers use wire of a reduced diameter and increase the mesh size compared to the stated ones.

To control the parameters of a woven mesh, it is enough to weigh the roll and compare the weight of a square meter of the mesh with the theoretical one. If the difference is more than 5%, then the quality of this roll is not all right. It can be shorter, smaller width, thinner wire or with an enlarged (weakened) cell.

Wire for galvanized mesh The chain-link can be covered with zinc in a hot way and galvanized.

We supply hot-dip galvanized wire mesh.

Galvanic galvanizing, or electro-galvanizing, gives a very thin layer of zinc, which is not enough to protect the galvanized mesh of the Chain-link for a long time from corrosion.

A thin layer of zinc can only be detected using instruments or laboratory tests.

We have such a device.

You can buy cheap galvanized chain-link mesh.

In this case, you run the risk of seeing a layer of rust on your galvanized mesh in a year or two.

After all, many small manufacturers of chain-link mesh use wire with a thin layer of zinc to reduce the cost of galvanized mesh.

Hot dip galvanizing promotes a larger layer of zinc.

GOST 5336-80 does not directly regulate the amount of zinc on the wire from which it is made.

He refers to TU 14-4-1563-89.

According to these specifications, the surface density of zinc on galvanized wire should be in the range of 50-70 g/m2. Such a layer of zinc ensures the service life of the galvanized mesh Chain-link for 15-20 years.

Some enterprises produce galvanized wire for the manufacture of grids with a brilliant coating.

This coating gives the attractiveness of the netting made from it, but its corrosion resistance is the same as that of the mesh Netting made from ordinary wire.

After a while, such a mesh Rabitz will fade in the air.

But it will still serve 15-20 years or more.

Modern technologies make it possible to increase the amount of zinc on the wire for the galvanized mesh Rabitsa up to 130 g/m2.

This is achieved by double or triple lowering the wire into the zinc melt.

You can buy from us a galvanized grid the Chain-link and with such increased galvanizing.

How much zinc is on a galvanized mesh Chain-link production of small enterprises.

Small enterprises do not have the opportunity to produce wire for galvanized chain-link mesh using an expensive hot method, therefore, in order to interest the buyer of fence materials to buy galvanized chain-link mesh with a low price, they use cheaper galvanizing methods.

Some galvanize the wire using a galvanic method, which makes it possible to produce wire for meshes with a surface density of zinc up to 10 g/m2, which is 5-7 times less than the required values.

Others buy cheap Chinese wire, which is soft, which is not suitable for mesh production, and has a zinc density of 10 -20 g/m2.

In China, there is also better quality galvanized wire, but it is not profitable to bring it to Ukraine, it is more expensive than domestic.

Third manufacturers of galvanized wire mesh Rabitsa use drawing ready-made galvanized wire of large diameters onto wire of smaller diameters.

At the same time, part of the zinc is lost and the surface density of zinc on such galvanized meshes decreases.

Galvanized wire mesh A chain link made from galvanized wire or overstretched galvanized wire may last less than you expected.

Therefore, it is worth hedging the results of laboratory studies of the density of zinc.

Another disadvantage of small manufacturers of woven galvanized mesh is that they do not have their own laboratory.

Therefore, they cannot give you the test results for each batch of galvanized chain link mesh.

In the production of woven meshes, they are content with data from wire quality certificates, or, in general, verbal guarantees from wire manufacturers.

This increases the risk of purchasing a galvanized chain-link mesh, the service life of which is short.

Even we have several times come across such poor-quality galvanized mesh Rabitz, what can we say about the usual buyer of wicker mesh!

Therefore, we recommend buying only factory-made galvanized chain-link mesh with a quality certificate.

You can buy the Mesh chain-link galvanized cell 60x60 mm from us at the best price in Ukraine. A wide range of products allows usquickly and efficiently fulfill any orders, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.