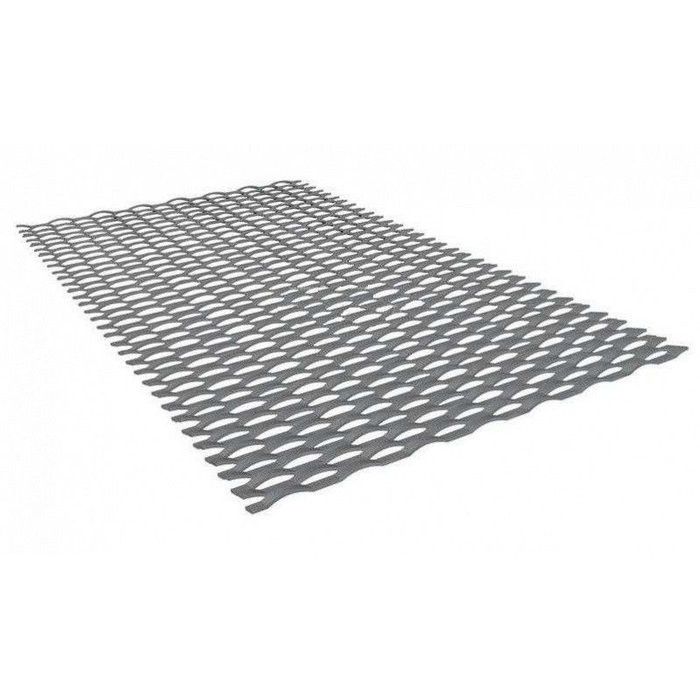

Galvanized expanded metal sheet 510 1000/2500, 1250/2000, 1250/2500, 1000/2000 is a kind of rolled metal, which is the result of processing a single metal sheet using a special technology. The main feature of products of this type are holes of the same shape, cut at a uniform distance from each other. Punching with subsequent drawing allows you to get strong and reliable sheets, the weight of which is 80% less than that of all-metal products of the same size.

Expanded sheets have excellent characteristics:

light weight;

resistance to aggressive external factors;

resistance to bending and deformation;

resistance to mechanical damage;

resistance to corrosion;

anti-slip surface;

heat, light, water and air permeability.

Galvanized expanded metal sheet is made from steel rolled metal with zinc coating. It is zinc applied to the surface of the metal sheet that gives the product maximum strength and resistance to corrosion. The anti-corrosion qualities of sheets are the main selection criterion in favor of this type of product. Galvanized metal is in demand in the construction of structures and fences, in industry, in interior and landscape decoration.

Expanded metal with zinc coating is used for the manufacture of decking, stairs, containers, elements of decorative partitions and fences. Products have an anti-slip surface, so they are used for arranging observation platforms, flyovers and walkways at enterprises. Sheet metal with notches is indispensable for the installation of viewing and ventilation windows in machine tools, agricultural machinery and devices. Due to the high light transmission capacity, products of this type are used for the construction of light-diffusing barriers on roads with oncoming traffic.

Expanded-drawn sheet (PVL) is a special metal-roll, which is made at factories from a whole sheet of various cuts or a roll, by punching and drawing, which allows obtaining high strength with a lower weight of the finished product. More specifically, it is a specific type of metal sheet that goes through a unique processing process. The essence of the process lies in the fact that multiple cuts (notches) are created on the source material, after which the material is stretched. As a result, a peculiar lattice with a regular pattern is formed.

Expanded metal sheets have a number of properties that make them indispensable in various industries. First of all, they are distinguished by high strength and resistance to stress. Thanks to a specific processing method, they acquire increased strength with a significantly lower weight compared to conventional metal sheets. In addition, such sheets are characterized by excellent ventilation and light transmission, which allows them to be used in a variety of areas.

The areas of application of expanded metal sheets are very extensive due to the versatility of their properties. In construction, they are often used as flooring for stairs, ramps and walkways, as well as in the process of fencing various areas. In these situations, their features, such as strength, lightness and anti-slip properties, come in handy.

In industry, expanded metal can be found in mechanical engineering and equipment manufacturing. Here they are used to manufacture machine elements, safety devices, filters and much more.

In architecture and design, this material is used to create unique decorative elements due to its unique look and ability to transmit light.

Of course, these are just a few examples of where you can find expanded metal. In fact, its scope is much wider, and it finds new areas of use as technology and science advance.

Thus, we can say that expanded metal is a versatile material that combines strength, lightness, unique decorative properties and the ability to transmit light. Thanks to these properties, it finds application in a variety of fields - from construction and industry to design and architecture. In the following articles, we will dive into the details of the manufacturing process, the advantages and disadvantages of this unique material, and take a closer look at its application in various industries.

PVL has a number of advantages that make it a truly versatile material.

As mentioned earlier, among the undeniable advantages of such raw materials is high strength. Many may doubt this, since the holes in the material are quite large, but due to the symmetry of their arrangement, the tension of the material is balanced, and the likelihood of serious deformation is reduced to zero.

The material is resistant to corrosion, since high-quality metal alloys are used for its production. For example, expanded steel sheet can last for many years and even ten years.tiya. This material is not afraid of sudden changes in temperature, so there are no territorial restrictions on use.

The presence of cells allows to reduce the weight of each sheet by about 80% (depending on the metals used in the alloy). It is this factor that simplifies not only operating conditions, but also transportation and installation features. In the manufacture of hinged structures, lightweight materials are most in demand, since they reduce pressure, and hence the risk of collapse.

PVL does not need any special care or cleaning. Thanks to the cells, liquid and small debris do not accumulate on the surface of the sheets, which also affects the appearance of rust and any damage. It can also be noted that any types of waste do not stick to the surface of the material, which means that they can be easily removed.

As previously mentioned, non-alloy steels and aluminum compositions that are resistant to corrosion are used for the manufacture of expanded metal sheets. Also, various non-ferrous metals and other alloys based on them are often used. The most common and reliable option is carbon steel sheets with any degree of oxidation. As for the dimensions, you should know that the parameters of each are provided for by GOST 8706-78.

The manufacturing process of expanded metal sheets has some features and consists of several stages. Let's consider each of them in more detail.

Initially, sheet steel does not have any holes and cells on the surface. Notches are applied using a special automatic knife, which is programmed for the required dimensions, shape, and location. So, holes can resemble in shape a geometric figure of a rhombus or large fish scales.

Then the material must be stretched in such a way that the perforated holes acquire the necessary - specified by the standards - dimensions.

Next, the resulting sample must be rolled along the long edge of the notches, thereby making it flatter. In addition, these manipulations will help increase the degree of resistance of the sheet to various kinds of deformations.

There are several varieties of PVL, the differences of which directly depend on the raw materials used in the alloy. Each material has its own advantages, which makes this or that type of sheet truly unique. In order to better understand what is at stake, we recommend that you familiarize yourself with the characteristic features of each type.

Hot rolled sheets. In the manufacture, thick metal blanks are used - slabs, which are pre-smelted in specialized open-hearth furnaces. Also, before production, each finished slab is machined or pickled to remove metal scale, which is harmful. Then, thin metal strips must be obtained from the machined parts, using a rolling press. The thickness of each strip should not exceed 50 millimeters. Hot rolled sheets have many advantages, including ease of manufacture, low market value and high strength. But do not forget about the shortcomings, which play an important role, since this type is subject to corrosion, and also has a rather unattractive appearance.

Cold rolled sheets. These products are made from hot-rolled samples by additional pressing. Production is complicated by the fact that the material is not subjected to a heating procedure, but for the same reason, the output strips are more even, stronger and of higher quality. Also, at the very beginning of the manufacturing process, the technology of mechanical or chemical etching is used. Among the advantages of cold-rolled sheets, they note a neater appearance, resistance to various mechanical loads, as well as to contact with chemical compounds and other liquids. The disadvantages include only the high cost of products.

Galvanized sheets. Obtained from galvanized sheet steel products, both cold-rolled and hot-rolled blanks are used. Both those and others previously undergo a galvanizing procedure by means of chemical or electromechanical action. In the process, a thin layer of zinc is applied to the metal sheet, which will later be covered with a protective oxide film. It is this double coating that makes it possible to minimize the contacts of the product with the environment, therefore, the galvanized sheet is not afraid of either long-term contact with water and other liquids, or any other influences.

As you know, the parameters of expanded metal sheets are regulated by GOST 8706-78, so absolutely all manufacturing enterprises should be guided by the established characteristics. They look like this.

Finished steel has a thickness of 3 to 6 mm.

The measured length of products is in the range from 2 to 3.5 m. In some cases, a sheet length of up to 4 m is allowed.

The width of products starts from 0.5 m and varies in steps from 0.1 to 1 m. The maximum value cannot exceed 1.25 m.

SoThe PVL rotation is represented by products with designations, each of which is characterized by certain parameters. Let's take a look at a few examples:

PVL-203 can have the following dimensions in millimeters: 1000x2000, 1200x2000 or 1250x2500;

for PVL-408, the parameters are 1000x1800, 1000x2000, 1000x2100, 1000x2200, 1000x2350 and 1000x2500;

PVL-608 has only one size - 1000x2000;

PVL-610 has only two options: 1000x2400, 1000x3000.

Application

Expanded-drawn sheets are actively used in various fields of activity and industry. They can be used both open and closed. The main purpose of their application is the reinforcement and strengthening of various structures. Often, PVL are taken for the construction and arrangement of stair structures. Thanks to the cells, the structure will not be slippery, which significantly reduces the risk of injury. And ease of care and cleaning will help to minimize maintenance costs. An alternative use case can be considered the beautification of sites used to support production processes, various transitions and fences.

Also, PVL can often be found as part of gazebos, fences, verandas and balconies. All of these objects, as a rule, relate to civil engineering. Thanks to the stainless coating, the sheets can even be used to build a podium for a portable swimming pool. In industry, this material is very popular due to its high mechanical properties. Expanded-drawn sheets are laid in the foundation, and are also used in the construction of other load-bearing structures. In some cases, they are even used to strengthen walls before rough finishing.

Often, PVL are used to equip observation platforms located at a height. This is because, due to the low windage of the sheet, it is very resistant to strong gusts of wind. Sheets are also used for the manufacture of protective grilles and ventilation channels in the national economy. Packaging containers, as well as containers for storing any product, are also often made from perforated sheets. In addition, the material is actively used in the mining and processing industries, as well as parts of screening machines.

You can buy Galvanized expanded metal sheet 510 1000/2500, 1250/2000, 1250/2500, 1000/2000 from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.