If measures are not taken to eliminate this extremely undesirable phenomenon, the pumped products released into the environment can cause significant harm, not to mention serious economic losses due to the significant loss of valuable product. In some practical cases, emergency situations even pose a threat to human lives, and equipment downtime can result in enormous losses. For these reasons, the seal used to seal the gap between the body and the sliding stem is of utmost importance when operating all types of shut-off and control valves with the design features described gland packing, successfully preventing emissions into the atmosphere even of gaseous working media under very high pressure.

Among its features, it is worth dwelling on the following in detail:

The basic raw material used for production is asbestos, obtained from the crystals of certain silicates. Cords made from it possess inherent resistance to high temperatures, making the material suitable for use in systems for redistributing superheated steam generated in boiler systems, suitable for both heating various spaces and for driving machine tools or turbines.

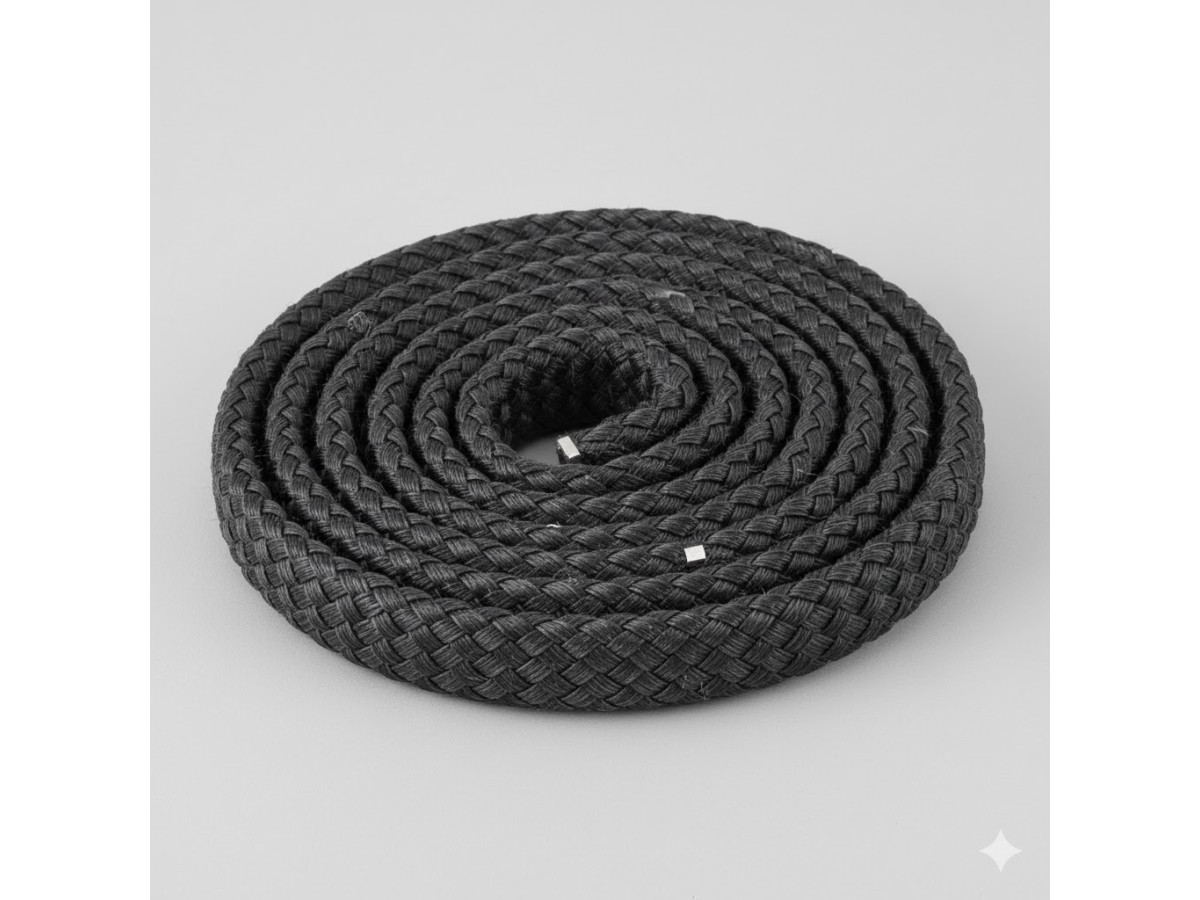

The product is very easy to work with, as a standard knife is enough to cut it into pieces of the required length, and a simple screwdriver is enough to compact it. Due to its high ductility, the pressure exerted by the locking flange or nut tightly fills the space between the piston rod and the housing, thereby ensuring a tight seal sufficient for operation.

By impregnating with graphite paste or mineral oil, the antifriction properties are enhanced, not only ensuring freer movement of the moving part, but also promoting the preservation of the seal due to the reduction of friction loads created.

Similar functions are performed by a cheaper one resin bead, used to seal the gaps between the end of one cast iron pipe and the socket of another during sewer installation. While high-temperature resistance and ideal sliding conditions are not required, the fibers used in production must be sufficiently resistant to the effects of fecal-feeding microorganisms.

Gland packing analogs used as seals

For fixed connections, using gland packing is impractical in most cases, so other materials are used, which are worth briefly discussing separately.

Paronitis

If you do not twist asbestos into a cord, but press its mixture with plasticizing additives and dry it, you can get paronitis, from which sheets of gaskets of any configuration are then cut. Such parts are capable of operating in much more challenging conditions than gland packing, for example, when joining parts of chimneys or internal combustion engines exposed to hot gases. The introduction of a metal mesh reinforcement cage significantly increases mechanical strength, expanding the range of applications under significant loads.

Technical plate TMKSh

If sufficient elasticity is required from the sealing element, it can be provided by TMKSh technical plate The rubber used as the raw material for its production can withstand acids, alkalis, and salt solutions without harm, making the product suitable for use on marine vessels and in chemical plants.