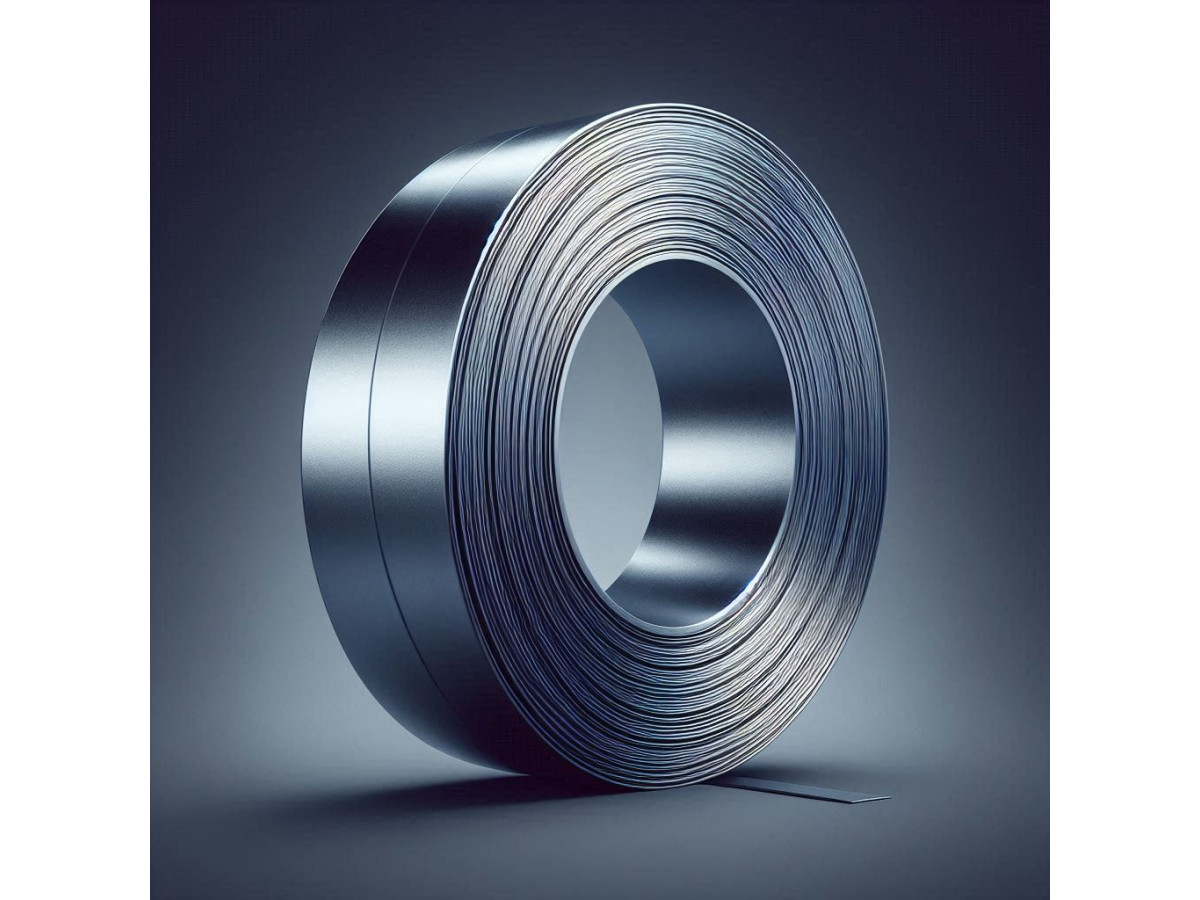

Galvanized strip is an irreplaceable material that is successfully used in various industries due to its unique properties. Strength, durability and corrosion protection make this material vital in creating reliable structures and metal products.

Types of galvanized tape

Galvanized strip is an integral component of many industries due to its varied types and applications. Each type of galvanized strip has its own unique characteristics, making them ideal for different applications. Here is an overview of the main types of galvanized tape:

- Cold-rolled galvanized strip - made by cold rolling of steel followed by galvanizing. This type of tape is characterized by high ductility and is used in construction, the production of household appliances and the automotive industry.

- Hot-rolled galvanized strip – produced by hot rolling galvanized steel. It is characterized by high strength and rigidity, making it ideal for use in the production of steel structures, pipes and other technical products.

- Electro-galvanized strip - obtained by electrolytic deposition of zinc on a steel strip. This type of tape has a thinner layer of zinc and is used in electrical engineering, small parts manufacturing and other areas where precise dimensions and surface are required.

- Polymer-coated tape – a layer of polymer coating is applied to the surface of this tape, which gives it additional resistance to corrosion and improved decorative properties. It is used in construction, furniture industry and other fields.

- Belt with various special coatings - these belts may have special coatings, for example, a lubricant to improve welding properties or a coating to facilitate sliding during processing. These types of tapes find application in various industries depending on their special characteristics.

Each type of galvanized tape has its own unique properties and applications, making this material indispensable in various industries of production and construction.

How to choose a suitable galvanized strip?

When choosing the right galvanized strip, it is important to consider the many factors that determine its performance and suitability for specific project requirements. Here are a few key aspects to consider when choosing galvanized strip:

- Type of galvanized tape: Different types of galvanized tape have their own characteristics and areas of application. It is important to choose the appropriate type (cold-rolled, hot-rolled, electro-galvanized, polymer-coated, etc.) depending on the purpose of use.

- Dimensions and parameters: The thickness and width of the galvanized strip must meet the requirements of the specific project. Choosing a thicker tape may provide additional strength, but ductility must be considered.

- Protective Coating Class: The zinc coating class determines the level of corrosion protection. It is necessary to select a tape with the appropriate class (for example, from G30 to G90 and above), based on the required oxidation resistance.

- Operating Conditions: Operating conditions play a key role in the selection of galvanized strip. Keep in mind temperature changes, exposure to moisture, aggressive environments and other factors to select the right tape with the necessary protective properties.

- Technical characteristics: Pay attention to additional technical parameters, such as tensile strength, elongation at break, the presence of protective ointment and others that are important for the successful implementation of the project.

- Price and Availability: Compare the prices and availability of different types of galvanized strip to find the best combination of quality and cost-effectiveness to suit your requirements.

Taking into account all the above factors, you can choose the most suitable galvanized tape that will provide reliable corrosion protection and long service life for your project. If you need advice or clarification of details, it is recommended to contact professionals in the field of materials and metallurgy.

Conclusion

Galvanized tape is an integral element in construction and production, which guarantees the safety of structures from the harmful effects of the environment. Thanks to a special zinc coating, galvanized tape is highly resistant to corrosion, which extends the service life of the material and ensures the reliability of structures. By choosing a quality specification and type of tape, you can be confident in the long-term reliability and effectiveness of using galvanized tape in your project!