Galvanized mesh is a multifunctional material characterized by corrosion resistance and high strength. It is an ideal choice for creating fencing, reinforcing structures and many other tasks. In this article we will look at production technologies, types, advantages and applications of galvanized mesh, and also give advice on its selection and care.

Secrets of production - technologies and materials

The raw material for the production of galvanized mesh is low-carbon steel wire. The source material goes through the stages of cleaning, rust removal, degreasing and pickling. The wire is then drawn through drawing dies to achieve the required diameter and strength. After this, the wire is unwound into coils and prepared for weaving or welding.

There are several ways to create galvanized mesh:

- rectangular weaving - the warps and weft are perpendicularly intertwined, forming cells;

- woven weaving - intertwined with each other, like threads in a fabric, forming a stronger base;

- welded weaving - elements are connected to each other by spot welding at the intersection points.

After weaving, the mesh is treated to protect against corrosion, this can be hot-dip galvanizing or electrolytic galvanizing. Depending on the operating requirements, the thickness of the zinc layer may vary.

Main types of rolled metal

There are many types of galvanized mesh that are used for various purposes. Here are some of the most common:

- Woven mesh is made by weaving wires in a checkerboard pattern. It is strong and durable and can be used for fencing, enclosures and other purposes.

- Chainlink mesh is similar to woven mesh, but it has larger cells, and is used for fencing, fences, etc., where less strength but more transparency is required.

- The hinged one consists of wire rings connected to each other. It is flexible and easily adapts to various shapes, mainly used for fencing, enclosures, and tree protection.

- Expanded metal is produced by cutting through sheet metal. It is strong and rigid; it can be used for concrete reinforcement, equipment protection and other purposes.

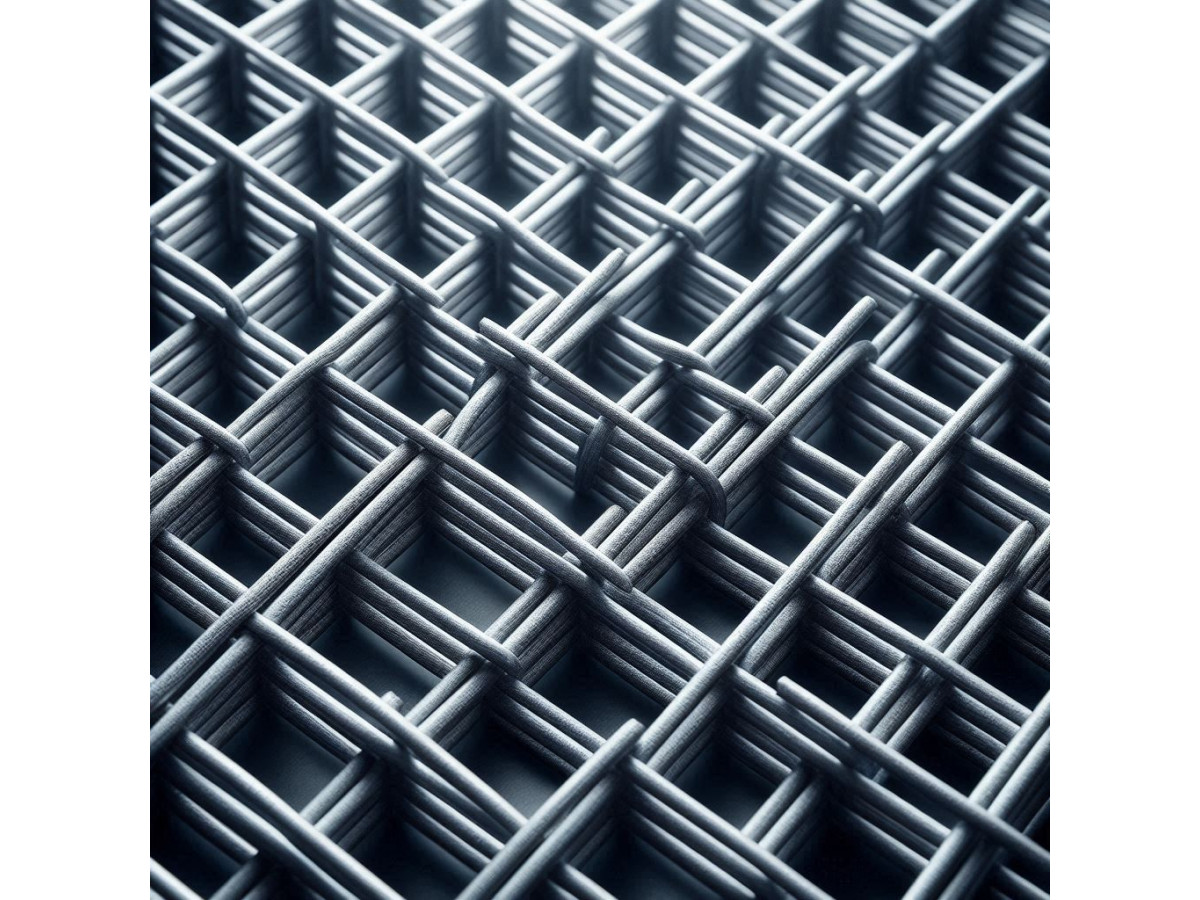

- Welded mesh is created by welding wires at intersections. It is strong and durable; rental can be used for fences, enclosures, concrete reinforcement, etc.

- The masonry option is used to reinforce brickwork; it helps to increase the strength and durability of walls.

- The canned type has cylindrical cells and is used for filtering liquids and gases.

- The plaster mesh is needed to securely fix the plaster; it helps prevent cracking of the coating.

- Manier mesh has diamond-shaped cells and is most often used for fencing and creating enclosures.

When choosing, it is important to choose the right wire diameter; the larger it is, the higher the strength. Buy mesh from trusted manufacturers, in Ukraine this is the company Ukrstarline. Products are always in stock and ready to be shipped to any region of the country.

Features and Benefits

One of the main advantages of galvanized mesh is its high protection against rust, which significantly increases the service life and reliability of the material. The material can withstand temperature changes, precipitation, and ultraviolet radiation without losing its properties. The mesh is easy to cut, bend, attach to various bases, it is lightweight, which simplifies transportation and installation.

This type of rolled metal is a relatively inexpensive material, so it is available to a wide range of consumers. It has an attractive appearance, which allows it to be used as a decorative element.

Installation and maintenance process

Proper installation and regular maintenance of the material are key factors affecting its durability and effectiveness. It is necessary to prepare the area, clearing it of debris and vegetation, and it must also be leveled and compacted. Defining boundaries and marking locations for installing poles and supports is the next step. The distance between the posts is usually from 2 to 3 meters, depending on the type of mesh and its purpose. The pillars are installed in prepared holes and fixed with concrete or other suitable material. For fastening, tension wires and fasteners are used, the excess is cut off, and the edges are folded.

The mesh needs regular cleaning from dirt, dust and vegetation. If corrosion is detected, it must be repaired immediately. It is necessary to ensure that there are no objects near the fence that could cause damage.