Fluoroplastic – is a modern material with outstanding features and used in various industrial sectors. Fluoroplastic rods, sheets and tubes will be an effective solution, used even in extreme conditions, are reliable, durable and practical. They are also resistant to chemical and mechanical influences, meet quality standards and hygienic norms. We suggest you familiarize yourself with the types, advantages and selection of this material.

Types of fluoroplastic

Several types of fluoroplastic are actively used in industry:

- F-2: This material is elastic and durable, resistant to chemical influences. The working temperature range is from -42 to +180 degrees. It is used as an additive for the manufacture of pipeline systems, thanks for transporting aggressive substances.

- F-3: The material is hard, durable, and becomes elastic when heated. Excellent adhesion properties and resistance to low temperatures make fluoroplastic suitable for the production of various complex elements and parts requiring anti-corrosion coating.

- F-4: Fluoroplastic products are characterized by increased density, minimal porosity, and resistance to temperature changes.

Thanks to the wide range, you can choose a material that meets quality standards and norms, suitable for performing tasks of any complexity. Fluoroplastic products are manufactured under the influence of high temperature and by pressing, due to which they have received unique qualities.

Advantages of using fluoroplastic today

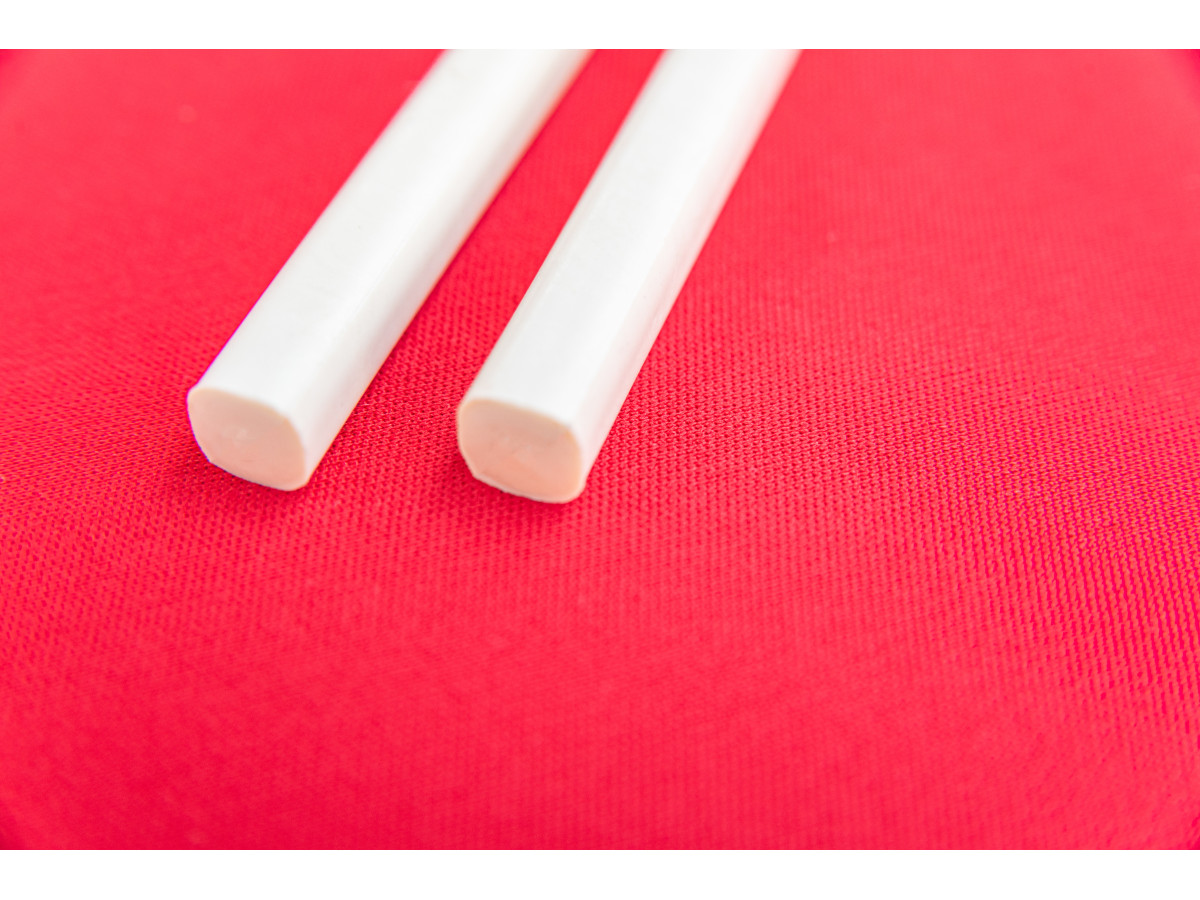

Fluoroplastic products, such as tubes, rods and sheets, have a number of advantages, due to which they do not lose their relevance and popularity:

- Chemical resistance: The material is not afraid of aggressive substances, resistant to acids, alkalis, solvents. Suitable for use in adverse and difficult conditions.

- High Temperature Resistance: Fluoroplastic rods, tubes and sheets can withstand up to 260 degrees while maintaining their original qualities.

- Minimal friction: The material reduces the risk of wear and friction of mechanical systems thanks to its anti-slip surface.

- Electrical insulation: Fluoroplastic is ideal for use in electrical engineering and electronics due to its excellent insulating properties.

- Resistance to corrosion processes: Rods, sheets and tubes made of fluoroplastic are not afraid of high humidity, do not rust and are not subject to corrosion.

Fluoroplastic is suitable for various purposes, regardless of their complexity. Such demand is due to its outstanding characteristics and operational properties.

How to choose fluoroplastic

When selecting fluoroplastic products, consider the following characteristics:

- Heat resistance: Consider the intended use of fluoroplastic products, especially if you are going to use them in an aggressive environment. The material must be resistant to organic solvents, acids and alkalis.

- Friction coefficient: Fluoroplastic has a fairly low coefficient of friction, making it suitable for the production of bearings and other mechanical parts that require minimal friction and wear.

- Electrical properties: Even under the influence of high temperatures, the material retains its properties, you can use it for its intended purpose, for example, as an insulator.

- Environmental friendliness: The material should not harm your health and the environment. When disposing of it, keep in mind that fluoroplastic is not subject to decay or destruction.

- Cost: Price plays an important role, it is higher than that of polypropylene, but fluoroplastic is more reliable and of higher quality.

Taking into account these criteria, you will be able to choose fluoroplastic sheets, rods or tubes that meet specific goals and objectives. Give preference to proven suppliers, choose materials that meet the necessary hygienic standards and quality standards.

Conclusion

Fluoroplastic sheets, tubes and rods are resistant to wear, negative factors, aggressive substances. They are strong, durable, practical, reliable, and can be used in various branches of industrial activity. The material is especially relevant for the manufacture of parts that require resistance to friction, corrosion, high humidity and temperature conditions. Fluoroplastic has unique characteristics, withstands chemical and mechanical impact. Various additives, such as fiberglass, graphite additives and other fillers, make products more resistant to mechanical damage.