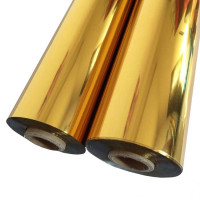

Brass ingot L63 - is the feedstock for the production of products by means of rolled metal. There are two types of rolled metal: cold or hot deformation. From the raw material, brass ingots, pipes, tape, hexagons, wire, rods and sheets are made. Brass ingot can be used for smelting alloys for various purposes as master alloys or independently. Brass ingots are produced in the form of ingots or bars, of various weights. On the domestic market, it is possible to buy brass ingots weighing from 24 to 27 kg. The maximum possible weight of an ingot does not exceed 45 kg. The production of brass ingots is carried out in accordance with GOST 1020-97.

Brass ingots are divided according to the following criteria:

• By shape (round, rectangular or hexagonal)

• By type of source material (chips, scrap, substandard ingots or brass ingots)

• By brand

LS59-1 brass is lead brass. LS59-1 lends itself well to pressure treatment. In its structure, it is a two-phase alloy. It has high strength and wear resistance. The addition of Zn and Pb to the alloy reduces the cost of brass ingot and improves machinability. To improve the corrosion resistance and resistance to mechanical abrasion, brass is subjected to heat treatment (annealing).

Brass ingot is widely used in heavy industry (aerospace, shipbuilding). Brass ingots are raw materials for the production of various casting alloys (as ligatures). A short list of applications for brass ingots:

- production of electrical equipment;

- oil refining industry;

-manufacture of parts of units and units of machines in aircraft and shipbuilding;

- production of furniture fittings;

-production of parts for musical instruments

Brass ingot is the raw material for the production of products by rolling. Pipes, tape, hexagons, wire, rods, sheets are made from it. Brass ingot can be used for smelting alloys for various purposes as master alloys or independently.

Brass ingots are produced in the form of ingots or bars of various weights. The maximum possible weight of an ingot does not exceed 45 kg. The production of brass ingots is carried out in accordance with GOST 1020-97.

Properties and characteristics of brass ingot

Brass is an alloy in which the main element is copper, and zinc acts as the main alloying element.

The alloy can be double or multi-component. To improve the technological properties of the brass alloy, such alloying elements as iron, nickel, aluminum, tin and lead are additionally introduced. Complex alloyed brasses have a number of advantages over alloys of the Cu-Zn system in terms of mechanical properties, corrosion and cavitation resistance. At the same time, good workability by pressure is maintained.

additions of such alloying elements as aluminum, tin and manganese effectively increase the temporary tensile strength in brass alloys, increase the ability to resist corrosion;

with the introduction of iron and a small amount of manganese, the relative elongation of the alloys increases;

Nickel additions also lead to a reduction in the susceptibility to stress corrosion cracking.

When these alloying elements are introduced, a dense oxide film is formed on the surface of the alloy, which protects the alloy from corrosion.

Due to high technological characteristics and mechanical properties at a relatively affordable price, brass alloys are widely used in mechanical engineering. Sleeves, cartridges, wire, radiator tubes, tapes are made from them.

Ingot brass LS59-1

LS59-1 brass is lead brass. LS59-1 lends itself well to pressure treatment. In its structure, it is a two-phase alloy. It has high strength and wear resistance. The addition of Zn and Pb to the alloy reduces the cost of brass ingot and improves machinability. To improve the corrosion resistance and resistance to mechanical abrasion, brass is subjected to heat treatment (annealing).

The chemical composition of brass brand LS59-1 includes,%:

Copper - 57 ... 60;

Iron - no more than 0.5;

Phosphorus - no more than 0.02;

Lead - 0.8 ... 1.9;

Zinc - 37.05 ... 42.2;

Antimony - no more than 0.01;

Beryllium - no more than 0.003;

Tin - no more than 0.3.

Production of brass ingots

Most brass ingots are produced by semi-continuous casting. This process is regulated by GOST 15527-2004 and GOST 17711-93.

The brass ingot is made in several stages:

the first stage is melting and refining of the alloy. The alloy is brought to the required chemical composition. The refining process can significantly reduce the content of impurities.

the second stage is the pouring of the liquid melt into molds of the desired configuration. Castings of brass are most often in the form of ingots. This is due to the convenience of storage and transportation of the obtained blanks (brass ingots).

The last stage of production is to carry outquality control of the obtained castings.

The following quality requirements are imposed on brass ingots:

the surface of the brass ingot must be cleaned of external defects and slag inclusions;

areas covered with oxide films should not exceed 1/6 of the total surface of the brass ingot;

the fracture of the brass ingot must be sufficiently dense and not include foreign inclusions.

Brass is an alloy in which the main element is copper, and zinc acts as the main alloying element. The alloy can be double or multi-component. In addition to zinc, it may include other alloying additives, but in much smaller quantities. Unlike pure copper, brass is characterized by increased elasticity and resistance to corrosion. This group of alloys combines good technological and mechanical properties at a relatively affordable price. Due to this, it has become widespread in mechanical engineering. To improve the technological properties of the brass alloy, such alloying elements as iron, nickel, aluminum, tin and lead are additionally introduced.

Complex alloyed brasses have a number of advantages over alloys of the Cu-Zn system. With complex alloying, it is possible to achieve the best performance in terms of mechanical properties, corrosion and cavitation resistance. At the same time, good workability by pressure is maintained. Multicomponent brass alloys are designated by the letter L, after which the alloying component is indicated. The numerical index indicates the quantitative content of the alloying element in the alloy. Binary alloys are designated by the letter L and a numerical index indicating the quantitative content of copper in the alloy.

The addition of alloying elements such as aluminum, tin and manganese effectively increase the tensile strength of brass alloys. With the introduction of iron and a small amount of manganese, the relative elongation of the alloys increases. All other elements reduce the tendency of brasses to relative elongation. Lead additives lead to a decrease in strength indicators. Fe practically does not dissolve in brass and is in the alloy in a free state. Aluminum, manganese, tin significantly increase the ability to resist corrosion. Nickel additions lead to a reduction in the susceptibility to stress corrosion cracking. The increase in corrosion resistance with the introduction of these alloying elements is associated with the formation of a dense oxide film on the surface of the alloy, which protects the alloy from corrosion.

In industrial production, foundry and wrought brass ingots are used. Brasses are divided into simple, two-component (the main alloying element is zinc) and special-purpose brass (contain, in addition to zinc, other elements).

Brasses with special properties take their name from the main alloying element in the alloy.

So, there are aluminum, silicon, manganese, tin, nickel, lead brass. Brass alloys have high technological characteristics. Sleeves, cartridges, wire, radiator tubes, tapes are made from them. Brass L59 is characterized by lower technological qualities compared to other alloys.

Special brasses have some specific differences from simple alloys. Aluminum brass have high strength. This is due to the strengthening effect of aluminum.

Brass products are distinguished by a wide range and areas of application. But each sphere uses mainly its own brands of brass alloys. So, the LS and LSch brands are often used for the manufacture of various types of fittings. Ingots with the brand LSd, LSdch and VOC are used in mechanical engineering. Also in the automotive industry, LMtsKA and LMtsSKA alloys are actively used.

For more complex components, the LK and LA brands are used. It is indispensable for units that will be operated in an aggressive environment. Grades LK1 and LK2 have found their application in the production of electronic components. The brass alloy LKS is indispensable for the manufacture of components with antifriction properties, and LMtsS is indispensable for the manufacture of components in the shipbuilding industry. The LAZhMts brand is necessary in the production of components operated under severe mechanical loads, and LMtsSK is required in the production of components used in hydraulic pumps.

You can buy Brass ingot L63 from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.