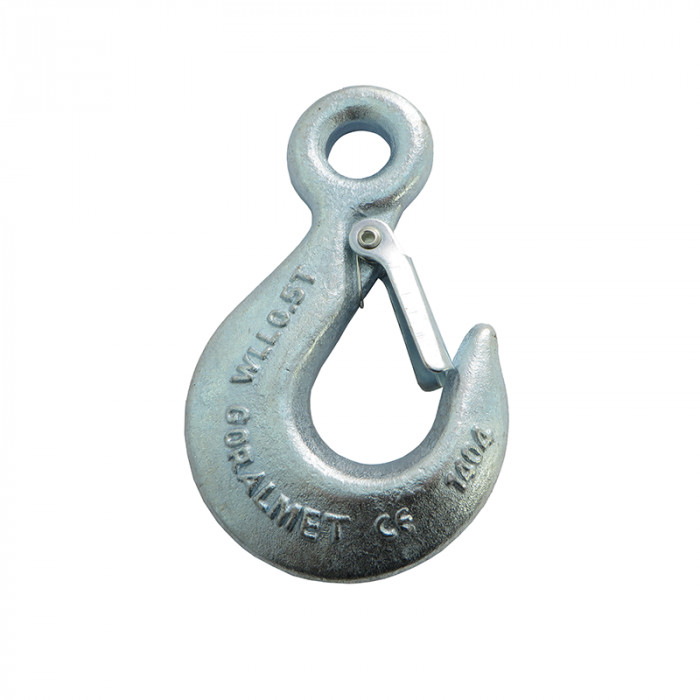

Crane hook DIN 689 - 8051 (9768) 1000 kg is intended for use in various lifting devices: on winches, cranes, hoists. Used in loading and unloading operations, construction, shipping. As a rule, it is attached to a chain or cable. Made from high-strength carbon steel and zinc coated to prevent corrosion.

A crane hook is a crane attachment point designed to connect chains and ropes attached to loads such as boxes, construction beams, and machinery. Hooks come in a variety of styles to suit different needs, and like other crane parts, they are designed to handle a specific size and type of load. It is important to avoid using an underrated crane hook as this may result in damage to the crane or loss of load.

Cranes allow people to move materials both horizontally and vertically. They vary in size, from truck cranes used on jobsites to massive equipment designed to move shipping containers at ports. Hooks are the preferred method of securing loads as they are easy to use and can be secured with locks if necessary. The crane hook can also connect to a wide range of connectors, allowing people to move different types of loads without changing the hook attachment.

Several people may be required to operate the crane. One person is responsible for securing the crane to the load and securing it, while another operates the crane under the direction of a person on the ground within line of sight. On a small construction site, one person can handle all these tasks. The personnel in charge of the crane are also responsible for maintaining the unit in good working order, as well as selecting the correct equipment for the specific lifting job. If the crane is not designed to handle heavy loads, it may tip over or break while lifting the load.

There are several safety concerns with crane hooks. A lowering hook can pose a safety hazard because crane hooks are large and can cause serious head injuries if someone is struck. It is important to ensure that loads are securely attached to the hook and that people are clear of the load during lifting and lowering. People should also be careful when attaching loads to the crane hook, as there is a risk of fingers or limbs getting caught in the load rigging.

In addition to being used to secure loads, the crane hook can also serve as an attachment point for crane fittings, such as a ball joint. The ball and tap fitting can be used to quickly demolish a structure in a demolition project. Crane manufacturers often produce a variety of accessories designed to work with their products, including different sizes of hooks and various attachments.

Hook material

And, in fact, what is a crane hook made of? Generally speaking, it is made of metal. There are cast, forged and plate hooks. The differences are in weight, price and reliability. They try not to use cast hooks due to possible hidden defects and cavities. Although they are suitable for small jobs, since the price of the hook in this case will be low due to the cheapness of the material and the relative ease of manufacture.

Purpose of the hook

In general, a hook is used to quickly connect and disconnect a cargo crane with a load. The simplest way to use it is to connect the hook directly to the main crane cable and load. What problems might arise from this?

The crane hook is loaded. Firstly, the weight of the hook may be insufficient. Simple cranes, or rather their cable release mechanism, are designed for “gravity flow”. Those. The reel with cable can only unwind under the influence of a load. This problem can be solved by choosing a more massive hook or hanging a small additional load on the rope. The “gravity flow” parameter of the cable must be looked at in the specifications for the crane.

Secondly, there are loads that need to be moved in a certain position. For example, a flight of stairs during the construction of a high-rise building. Such loads require multi-point gripping. In this case, the use of slings is already necessary. Mooring hooks are attached to the ends of these slings. Those. Several hooks are used simultaneously on one crane. A double hook is often used to distribute the load.

Thirdly, the steel rope of a crane is a thing that is difficult for human hands to handle. Changing the angle at which the hook and load meet is often extremely difficult. And here we move to the next point:

Types of hook fastening

The base hook has an eye on top. A rope is threaded into it. If you have a chain, then you need to use a fork hook connection.

For convenience, it is often necessary to use a swivel. This is the upper part of the hook that rotates freely around its axis, greatly simplifying the work of the slinger.

There are also extreme options. For example, an “S”-shaped hook. It has identical top and bottom parts.

Now let's take a closer look atthe lower part of the lifting hook. As I have already said, in addition to the standard one-horn hook, there are double-horn ones, which are used for more stable transportation of goods.

From us you can buy Crane Hook DIN 689 - 8051 (9768) 1000 kg at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any orders, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.