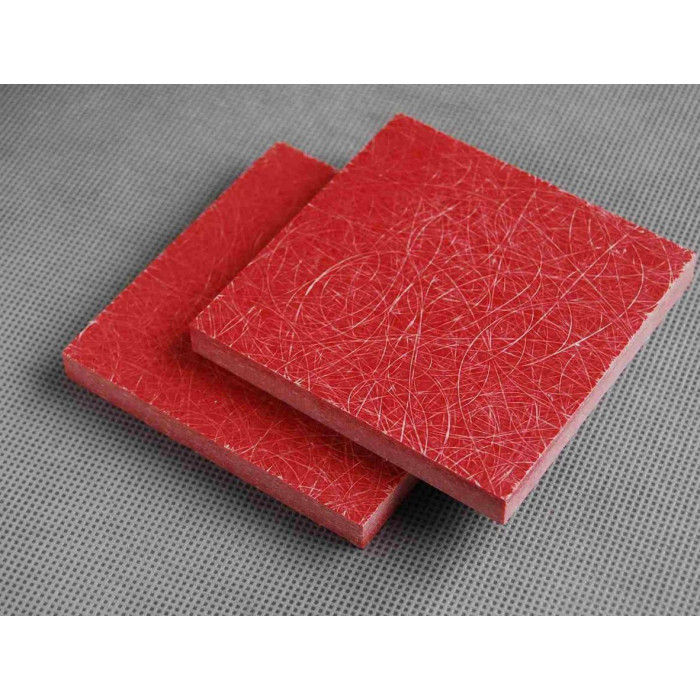

Duroston GPO3 1000х2000х4 mm, made on the basis of unsaturated polyester resin and glass mat. It has a homogeneous structure, combines high structural and dielectric qualities, temperature and chemical stability with low flammability. Maximum operating temperature 385 degrees C (10-20 sec). Does not contain phenolic and asbestos components, halogens. Applications: - arc chutes - insulating busbar holders - high and low voltage circuit breakers - switchboards - switchboard mounting plates - switchboards for electric vehicles - power electronics - phase barriers.

Country of manufacture China

Warranty period 12 months

Hygroscopic No

Thermal conductivity coefficient 0.3 W/(m*K)

Maximum operating temperature 385 degrees.

The minimum working temperature is -10 degrees.

Young's modulus 250 GPa

Density 1.87 g/cm3

Porosity 2%

Hardness 158 HV

Material toxicity Yes

Impact strength 230 kJ/m2

User specifications

Insulation class F

Compressive strength 250 perpendicular to the layers

Thickness 2mm

Impact strength 80 parallel layers

Insulating material with a beautiful name in the French manner - Duroston, is fiberglass. It is made by mixing fiberglass with vinyl ester, polyester, epoxy resins. We can say that this is reinforced plastic, which received fiberglass armor. In terms of strength, this polymer is superior to other layered electrical insulating materials, as well as in terms of thermal and chemical characteristics. If we compare with foreign analogues of the same raw material class, then duroston is comparable to glass fiber laminates of such brands as STEB, STEF-1, STEF, STEF-U.

The material is characterized by thermal and chemical resistance, excellent dielectric properties. Therefore, duroston has found application in the industrial sector as a structural and electrical insulating material. Often duroston is used:

in arc chutes;

as an insulating material for busbar holders;

for the arrangement of switchboards;

for isolation of the block of low-, high-voltage switches.

As for the color performance, the material can be gray, red or white.

Since duroston has high structural strength, chemical and thermal resistance, its use involves extreme environmental conditions. The insulator retains its original strength even under the condition of prolonged exposure to temperatures ranging from 200 to 280 °C. The maximum passport value (maximum operating temperature) is 385 °C. But, even at such high temperature values, the composite does not deform, remaining flat and smooth for 10-20 seconds. From this it follows that duroston is excellent for production lines that generate a large amount of thermal energy (according to RoHS standards).

Mechanical characteristics and advantages of duroston

Thanks to its dimensional stability and increased rigidity, duroston can be processed mechanically. This fact makes it possible to use the polymer in the manufacture of structural components of non-standard shapes and sizes. Duroston has been measured to have a tensile strength of 20,000psi in static bending. At high heat, this value drops to 15000psi.

From the above, we can draw the following conclusions about the benefits:

excellent chemical inertness;

dimensional stability under any operating scenarios;

highest mechanical strength;

close to record antistatic performance, turning duroston into the best insulator.

high accuracy in dimensions, layer thickness and other physical parameters.

Of all the insulating materials, duroston is the most technologically advanced and versatile composite.

Characteristics of products made of polyester fiberglass

Duroston products are available as thin base plates or soft mounting plates. Composite can also be found in the form of baseplates supporting non-standard cases. To improve performance, several panels are linked together. An insulator is often used when soldering at high temperatures to protect the backing plates. Duroston is considered an ideal base for applying Teflon coating. With it, the edges of the board are protected from contamination that may remain from the touch of human hands.

If the job involves wave soldering, protecting SMT components with Duroston is indispensable. During welding, duroston protects the base plates from deformation. On rare occasions, insulator plates serve to standardize the width of a production line, or to protect the outer layer of any surface from tin or contaminants.

If we try to reduce the information about the areas of application of duroston to the size of a short list, we get the following list.

Wave solder, SMT, "classic" soldering

Screen printing

surface mountas much (SMT)

On-site testing (creation of frame structures)

Solder crystallization (composite melting by means of infrared radiation)

Despite the fact that duroston is not explosive and non-toxic, safety precautions must be observed when working with it. In particular, during the mechanical processing of the composite, dust harmful to humans, consisting of a fine suspension of fiberglass and polyester resin, rises into the air. Therefore, when cutting material, use a respirator and goggles.

Physical and mechanical properties of duroston

We have already talked about the strengths of this composite, and now we can proceed to a more detailed review of the “subject” in numbers. Note that all the values below were obtained within the framework of tests standardized by the international systems ISO, IEC and METTLER TMA.

Density - 1.82 g / cm3

Compressive strength – 250 N/mm2

Elasticity – 9000 N/mm2

Bending strength - 129 N/mm2

Water absorption - 0.2%

Tensile strength - 70 N/mm2

Current and leakage resistance - CTI 600

Separately, we single out a high level of resistance for current breakdown. The insulator withstands 72 kV/mm at 90°C, which is sufficient for any extreme operating scenarios.

Duroston is made by the method of hot pressing. The plates are produced in five popular sizes: from 2 to 50 mm thick (2x1.25 m), from 0.8 to 3 mm (2.02x1.02 m), from 1.6 to 50 mm (2.47x1.25 m ), from 55 to 100 mm (1.95x1.2 m).

Most often, duroston is considered as a worthy replacement for asbestos-containing sheets, grade ACEID, due to lower water absorption, as well as arc and electrical resistance. On the world market, duroston is commercially labeled GPO3+, GPO3. The GPO3+ grade has improved bending strength, elasticity, impact strength and tear strength compared to GPO3. But at the same time, it is inferior to the brand without a “plus” in terms of breakdown voltage resistance.

DUROSTONE UPM 203

Layered fiberglass imported (Germany). Duroston UPM 203 is produced by hot pressing glass mat and binder, based on modified unsaturated polyester resin and fillers. The material has a homogeneous structure, has dielectric and structural properties. Duroston UPM 203 is arc resistant. The material is used as a replacement for previously used materials containing asbestos. Duroston UPM 203 is used for the manufacture of arc chutes, low voltage circuit breakers, switchboards, insulators, etc.

Various grades are available (based on polyester binder, based on epoxy resins, as well as specialized grades)

Based on polyester binder:

DUROSTON UPM Grade S2: It is a laminate based on glass mat and fabric impregnated with modified polyester

DUROSTON Grade UPM 203: It is a laminate based on glass mat impregnated with a modified polyester binder. It has increased arc resistance. Produced in red and white colors.

Sheet size 2020*1020 mm, 2440*1220 mm, 2470*1250 mm

sheet thickness from 0.8 to 80 mm

binder. It has improved mechanical properties. It is produced in white color, sheet thickness is from 4 to 50 mm, sheet size is 2340*1120 mm.

DUROSTON Grade UPM S1:

DUROSTON Brand UTR: available in red and white colors, thickness from 0.8 to 50 mm sheet size 1828*914 mm, 2445*1255 mm

DUROSTON Brand 1580: bulging in white, sheet thickness from 0.8 to 2.4 mm, sheet size 1828 * 914 mm

DUROSTON SG200 brand: available in white color, sheet thickness from 0.8 to 50 mm, sheet size 1828*914 mm, 2445*1255 mm

DUROSTON FHT brand:

DUROSTON UPM S13 LST: It is a laminate based on glass mat impregnated with a modified polyester binder. available in white, sheet thickness from 4 to 50 mm, sheet size 2440*1220 mm,

You can buy Durostone GPO3 1000х2000х4 mm from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.