Polyacetal (ROM-S), sheet, thickness 12.0 mm, size 610х1220 mm is an anti-friction thermoplastic material, which is also called polyformaldehyde or polyoxymethylene. This polymer has a high level of elasticity, resistance to stress and wear resistance, due to which it has been widely used in various industries.

Characteristics of Polyacetal:

• High mechanical strength, stiffness and hardness

• Very high elasticity, resilience

• Good resistance to flow (creep)

• High impact resistance, even at low temperatures

• Good dimensional stability, also at high humidity.

• Good sliding properties and wear resistance

• Stability of properties in a wide temperature range (from -50 to 100 degrees C)

• Excellent machinability

• Slight moisture absorption

• Good electrical insulating and dielectric properties

• Physiologically inert (approved for food contact)

• High resistance of black materials to UV rays

• Allows for laser marking

• Not resistant to strong acids and oxidizing agents, resistant to organic solvents, fuels of all types, alkalis

Areas of application of Polyacetal: Mechanical engineering, precision instrumentation, food industry, automotive industry, electrical engineering, medical industry, textile industry, paper and packaging industry, household appliances, etc.

Parts made from polyoxymethylene are designed for continuous operation in the temperature range from -50°C to +90°C. They withstand short-term heating up to 140°C.

Polyacetal sheet (plates) POM-S engineering plastic with high elasticity, bending and tensile strength, operating temperature from -50°C to +90°C, for a short time from -60°C to +135°C. The polymer polyacetal is resistant to shock loads, can work in water, reduces friction, is a dielectric, does not break down in oils and weak acids, can replace metals and alloys.

Polyacetal sheets (plates) POM-S (also corresponds to the name - POM, polyoxymethylene, polyformaldehyde) is a raw material in the production of parts for machine tools, machines, cars, spare parts for electrical equipment and light industry. POM-S is easy to process, the accuracy of parts is up to 0.01 mm. Polyacetal in the form of plates and sheets is used to make seals, instrument panels, parts of broaching mechanisms, conveyor belt modules...

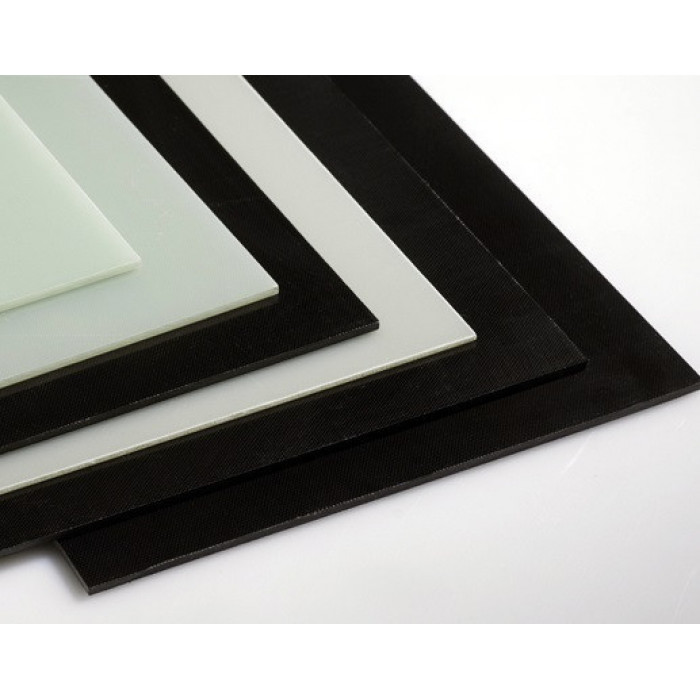

Sheet polyacetal (plates, blocks) is supplied with a thickness of 5 to 30 mm, sheet sizes 1000*1000 mm, 1000*2000 mm. We offer polyacetal POM-S (standard polyformaldehyde), made in accordance with GOST according to STO-002-17152852-2011.

Plates are supplied cut 1000x1000 mm, we can cut you to size or make parts according to your drawing, sketch or sample.

Sheet polyacetal is a material that, due to its excellent performance, has received a wide range of applications. The distinctive advantages of polyformaldehyde include: a high level of elasticity, good protection against loads, resistance to wear and the harmful effects of organic components and excellent anti-friction properties.

Where is polyacetal sheet applied?

In fact, polyacetal sheet is an excellent replacement for thermoplastics and non-ferrous metals. Most often, the product is used in the production of electronics, in the automotive, paper, food, textile and mechanical industries.

Pom Sheet Benefits

In addition to the advantages indicated in the first paragraph, the pom sheet is also characterized by a number of other advantages. Namely:

low coefficient of friction;

high mechanical strength during compression (>120);

resistance to strikes;

impeccable degree of elasticity and elasticity;

temperature resistance

necessary electrical insulation;

worthy protection against the negative effects of disinfection, weak alkalis, various oils, solvents.

Properties and characteristics of polyacetal POM-S (POM)

Polyacetal POM-S (polyformaldehyde, polyoxymethylene C cast, extrusion) is a polymeric material, engineering plastic for structural purposes with highly effective physicochemical and operational properties and characteristics, is used in many areas of modern industry, where parts made of metals and alloys are often replaced by polyacetal polymer. POM-S polyacetal has a highly crystalline structure and combines a high tensile and flexural modulus with a sufficiently high impact strength, it is one of the best materials for products that are subjected to repeated mechanical stress, shock loads, stretching and vibration. POM also has good anti-friction characteristics, high resistance to organic solvents, alkalis, technical liquids (except for concentrated acids), and ultraviolet radiation. The polymer is easy to paint, allows laser marking, welding proremoved using ultrasound. POM-S polyacetal practically does not absorb moisture; acetal parts are used for working in water.

You can buy Polyacetal (ROM-S), sheet, thickness 12.0 mm, size 610х1220 mm from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.