Elevator tape 300х4 mm BKNL-65 are designed for a seemingly quite simple process - transporting grain from point A to point B. But the fault tolerance and durability of its operation depend on how high-quality this belt is.

Elevator belts are made on the basis of rubber-fabric materials (in particular, BKNL-65 fabrics). Made from this fabric and other products.

Elevator belts have a very simple design, which allows them to be used in almost any conditions. They consist of a working rubber lining, a fabric lining and a non-working lining.

Ladle

The elevator bucket is the main transport element in various types of bucket elevators. Are intended for vertical transportation of grain and products of its processing. Elevator buckets are made of sheet steel of various thicknesses and are bolted to the elevator belt. Elevator buckets, solid-drawn, stamped polymer, elevator buckets are used on bucket elevators (bucket elevators) to move grain, seeds, flour, bran, mixed fodder and other bulk products. They are installed on a conveyor belt, the so-called bucket elevator, which is designed for vertical lifting of bulk materials.

For the full operation of elevators transporting various goods, a special elevator or elevator belt is required. This is one of the main structural elements that sets the elevator in motion and performs a number of important functions. Almost all modern drive, rubber-fabric belts are equipped with an elevator belt, so manufacturers offer a wide range of belts with different technical characteristics. What are the features of the elevator belt and how it is produced, then we will consider in more detail.

Where is elevator belt used?

The scope of the elevator belt is quite extensive, but most often it is used in agriculture and in various warehouses where grain and other bulk materials are stored. In addition, the tape is used in large industrial enterprises engaged in the production and sale of animal feed.

Various units are equipped with an elevator belt. Here it performs the main, traction function and sets the equipment in motion. Belts help to quickly and safely transport lumpy and bulk materials, so they are often used in conveyor production.

How is tape made?

For the production of belts, special equipment and materials are used, so manufacturers produce several types of belts with different characteristics. On sale there is a large selection:

general purpose tapes;

frost-resistant tapes;

antistatic belts.

The strength of the belts is also different, which varies from 150 to 300 N/mm. The width of the elevator belt can be up to 1.2 meters, depending on the model.

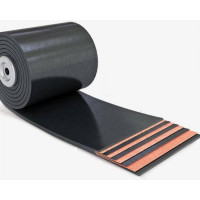

The elevator belt consists of:

A frame that acts as the main load-bearing element. It is made from various fabric pads, the number of which may vary.

Rubber linings located on the canvas. General purpose tapes may not have such covers. In other belts, their thickness ranges from 1 to 5 mm.

For the convenience of buyers, the main technical characteristics of the belts are indicated in the marking. To do this, apply special digital designations indicating:

thickness;

width;

tape type;

number of pads.

Also on the tape there are letter abbreviations indicating the materials from which the covers are made. For example, you can purchase a BKNL-65 belt, in which the letters indicate the type of lining fabric.

Advantages of the elevator belt

Elevator belts are produced according to the standard, so each stage is strictly controlled, and the elevator belt has a lot of advantages. The elevator belt has:

high transverse rigidity;

increased wear resistance;

low stretch;

good elasticity.

Thanks to this, the belts withstand heavy loads and other adverse factors, therefore they can be used in various industries. The elevator belt has improved characteristics and lasts for years, which makes it popular.

In some models of belts, small buckets are additionally installed, for the convenience of transporting goods. These belts are more expensive, but they are more convenient to use and greatly facilitate the work.

Both domestic and foreign companies are engaged in the production and sale of elevator belts, so buyers have an excellent opportunity to choose technical specifications and manufacturers.

It is better to buy belts from trusted companies that monitor production and give all the necessary guarantees. Belts are not cheap, so you need to carefully study their features and the reputation of the supplier.

The following main considerations are taken into account when choosing a belt: cost, appropriate transverse stiffness, longitudinal elasticity without requiring too large drum diameters, low stretch, resistance to lubricants, antistatic characteristicssticks, moisture resistance and high wear resistance.

In normal operation, the load on the belt includes the sum of all loads due to: transport height, weight of the load and buckets on the belt, idle belt tension, and bailout resistance. Dynamic loads at start-up are usually taken into account by the calculated safety factor.

The tensile strength of the tape depends on the fibers used and the number of layers. The currently widespread elevator belts consist of synthetic fibers (longitudinal fibers are polyester, transverse fibers are polyamide). To increase tensile strength and transverse stiffness, multiple layers of fibers are bonded together to form a carcass that has minimal elongation at very high tensile forces. The most important advantage of this type of elevator belt is that a higher tensile strength is achieved without a significant increase in the dead weight of the belt. This allows you to increase the height of noria.

The transverse stiffness for an elevator belt is much more important than for a conveyor belt. The elevator belt has almost no support between the drive and lower drums. This can cause the belt to warp as it moves, which in turn results in poor belt centering.

It is very important that the elevator belt has a minimum elongation. Limited elongation requires belt tension adjustment less often, belt has to be shortened less, it does not slip, fire hazard is reduced, elevator bolt holes are less deformed, and overall belt life is increased. Usually the total elongation of the tape at maximum load does not exceed 1-2% of its length. For an additional charge, some companies supply tapes subjected to pre-stretching. This allows you to select a tape with a higher tensile strength.

The tensile strength of the elevator bolts is important. The typical load on elevator bolts consists of the drag resistance, the mass of the contents of the bucket, and the loads that occur when the bucket passes over the drums. In addition, foreign objects can be introduced into the product stream, causing additional shock loading on the buckets. The tensile strength of elevator bolts is almost directly proportional to the tensile strength of the belt. A high tensile strength is a elevator belt with a dense layer or carcass structure and a low elongation.

In continuous operation, elevator belts are sensitive to various mechanical stresses that can cause wear. On the underside of the belt, wear can be the result of, for example, friction between the belt and the drive drum, product backfill and crushing between the bottom drum and the belt, or rigid buckets that put additional stress on the belt as they pass over the convex drive drum. On the side of the belt where the buckets are attached, wear is caused by, for example, grains getting caught between the back wall of the bucket and the belt, contact with the product flow, and deformation of the belt around the elevator bolts. This indicates the importance of the tape protective covers, protecting the frame from damage. The linings also prevent lubricant and moisture from penetrating into the fiber layers. The flat heads of the elevator bolts are pressed into the soft rubber base as they are attached; thus their contact with the drum rim is minimized.

Careful connection of the ends of the tape is important, since its strength is judged by the weakest point. Several joining methods are possible, including vulcanization, lap joint, lap joint, and stapling or clamping. Cure bonding is the least of a hassle, but tape stretch issues and initial elongation usually make this undesirable.

Theoretically, under ideal operating conditions, the gap between the drum and the casing or the belt and the elevator pipe should be as small as possible. However, in practice, operating conditions are never ideal, so the gap must be such that the movement of the belt is free. A serious danger is an incorrectly installed tape that touches the elevator pipe. The contact area is usually very small, resulting in very rapid local heating. A reduction in belt speed or an increase in motor load due to friction is usually hardly noticeable. Belt misalignment can be caused, for example, by misalignment, tilted elevator, worn drum surface, misalignment of the drum on the shaft, non-horizontal drive shaft, uneven loading, uneven belt pull due to moisture absorption, backscattering of grain caught between the belt and bottom surface. drum (product sticking to the surface of the drum), poor design of the tensioner, insufficient weight of the load of the tensioner.

For large elevators, the following operating clearances are recommended:

the inner width of the elevator pipe is 150–200 mm greater than the width of the belt, which, in turn, is greater than the overall width of the bucket;

drum width by 80—100 mm more than the belt width; gap between the front edge of the bucket and the elevator pipe 100-130 mm;

the gap between the tape and the elevator pipe is 60-80 mm.

Belt alignment control devices, or "friction sensors" at the bottom of the head and shoe of the elevator, mounted on either side of the elevator tube, must actuate before friction begins and stop the elevator belt.

The elevator belt device includes the following elements:

frame - 2-8 layers of BKNL 65 material;

rubber layers - parts are installed on the outside and the wrong side of the material (flat belts are made with or without linings.

Based on the purpose, elevator belts are divided into the following modifications:

general purpose (layer of rubber or without it, from -60 to +60 °C);

heat-resistant (have a layer, from -60 to +60 ° С);

antistatic with interlayer;

oil-resistant, also equipped with an interlayer.

According to the established requirements, elevator belts must have the following technical characteristics:

rigidity in width;

low stretch;

wear resistance;

flexibility;

antistatic;

resistance to chemicals, lubricants.

The elevator belt is equipped with buckets made of metal or polymers, which are bolted to it.

The conveyor belt is the main traction component, which is part of the flat-belt transmissions of various units operating in production. For example, grain belt elevators equipped with an aspiration system are mounted at agricultural enterprises for processing and moving low-abrasive bulk materials. In the metallurgical, chemical, mining and glass industries, elevator belts are used in elevator equipment with steel buckets.

Here you can buy Elevator tape 300х4 mm BKNL-65 at the best price in Ukraine. A wide range allows us to quickly and efficiently fulfill any orders, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.