Rubber compound 7v 14 is a compound of specially prepared rubber and other components, including stabilizers, fillers, vulcanizing agents, plasticizers, and so on. The choice of additives depends entirely on what products will be made from the mixture, however, the main characteristics depend on the brand of rubber, which is the basis of the mixture.

Unvulcanized commercial rubber compounds that are used for the manufacture of a variety of rubber-metal and rubber parts designed to work in various conditions and under various loads; - calendered rubber compounds, which are used for the manufacture of various parts in the aviation industry, gumming of chemical equipment, and so on.

The price of a rubber compound can vary quite a lot depending on the brand of the rubber compound, the type of rubber used, the degree of filling with other ingredients. In the course of production rubber mixes pass quality control on the modern equipment. Control stages include: — 100% input quality control of incoming raw materials; – determination of all the necessary physical and mechanical characteristics, the study of the resistance of rubber to the effects of a variety of aggressive media under standard conditions and at high temperatures; – determination of the bond strength of rubber with reinforcing material; — determination of brittleness temperature; — determination of ozone resistance; - etc.

More than 50 types of raw mixes are produced (IRP mix 1265, 3826, 2825, 6190, 1347, 1287, 1225, 1314, 1345, 1338, 1267, NO 68, PI 52, calendered rubber, rubber for vulcanization, rubber for repairing tires and tubes (repair) and many others) and in order to choose the right type of rubber compound, it is necessary to determine the conditions under which the vulcanized rubber product will work, i.e.:

- temperature mode of operation of the vulcanized product;

- the maximum possible high and low temperatures of impact on the rubber part;

- chemical aggressive substances that will act on the vulcanized product constantly;

- reagents and environments that can act for a short time;

- the nature of the work of the product - what physical effects are on the rubber part;

- technological processes for the manufacture of rubber products.

A rubber compound is a multi-component elastomeric homogeneous system that includes rubbers (natural and / or synthetic), vulcanizing agents (most often sulfur or organic peroxides), factices, oils and other plasticizers, carbon blacks, chalk, kaolin, white soot, other fillers and other components (ingredients). The rubber mixture is intended for the manufacture of rubber products (vulcanizates, vulcanized products) by vulcanization (molded or non-molded) - most often high-temperature.

The technological process for the manufacture of rubber compounds is a mechanical, most often sequential mixing of rubbers and ingredients on special technological mixing equipment - on mixing rollers or in a closed-type rubber mixer (Banbury or Intermix) or open. The trivial name for the rubber mixing process is rubber dyeing. In mass production for the manufacture of rubber compounds, technological lines are used, including:

rubber mixer - for displacement of rubbers and main components;

mixing rollers or an assembly of several - 2 or 3 rollers for finalizing the rubber mixture by introducing a vulcanizing agent (sulfur, less often thiuram D) into the mixture and sheeting (giving a convenient commodity form);

scallop-type cooling unit or cold water bath to reduce the temperature of the rubber compound and prevent scorching (scorching)

In the recent past, the manufacture of rubber compounds has also used a two-stage method, in which the rubber compound, before the introduction of a vulcanizing agent, went through a curing step, either in the form of sheets or granules. In small-scale production of rubber compounds, production is carried out only on mixing rollers.

The use of rubber compounds

In the modern world, not a single large-scale production is complete without the use of these mixtures. This indicates their huge popularity and exploitation in various fields. Now there is an opportunity to buy rubber compounds at www.niirpi.com, choosing the necessary ones according to the purpose. The following areas of use of rubber compounds can be distinguished:

Manufacture of electrical insulating parts and protective equipment when working in a state of high voltage.

Manufacture of rubber products (RTI) for the aviation, oil and gas and automotive industries.

Production of closing elements in electronic equipment for various purposes.

Production of elements of the electrical industry (heat-shrinkable tubes, cable insulation, wires and cables of various sections, etc.).

Production of all kinds of seals in the aviation, machine-building and household sectors.

Productionin thermal and oil-resistant, anti-corrosion coating of products made of various metals.

Production of a fire-resistant coating that provides protection for all kinds of materials.

Benefits of rubber compounds

Considering all the chemical and technical features of this material, we can talk about a huge number of advantages, among which

High thermal stability.

The maximum degree of compression under temperature exposure.

Vulcanization of polymers.

Unpretentiousness to warehouse storage.

Enhanced dynamic properties.

Ease of preparation.

High density and minimal tensile strength when heated.

High resistance to aging and wear of rubber.

Thus, any modern production of mechanical engineering, aviation, oil and gas production is not complete without the use of various rubber compounds. When choosing a given substance, it is important to take into account its composition and scope, since various chemical compounds are not always suitable for use in any area.

Raw rubber compound 7-B 14 is a multi-component raw material made from rubber with various additives (fillers, stabilizers, plasticizers, etc.). This brand of rubber compound is widely used in various industries: construction, automotive, chemical production, etc.

This rubber is used to make sealing products, rings, caps, cuffs for hydraulics, oil seals, tubes, mud and oil scraper products. In addition, such rubber is used in the repair of automotive tubes and tires, gumming of chemical equipment, the production of aircraft parts, in the shoe industry and for the manufacture of cables. When repairing car tires, the 7-B 14 mixture can be used both to restore the hard part of the tread, and to repair the soft, side part of the tire. And the good fluidity of the rubber allows you to securely put patches, overlapping the edges with a margin and excluding perforations.

Such a wide range of applications is due to the properties of this brand of rubber. A mixture of 7-B 14 is used for the manufacture of parts that are resistant to air, dirt, oils, fuels, alcohols, petroleum and weak acids. Products from this brand of rubber can withstand temperatures up to 100 ° C and have a long service life.

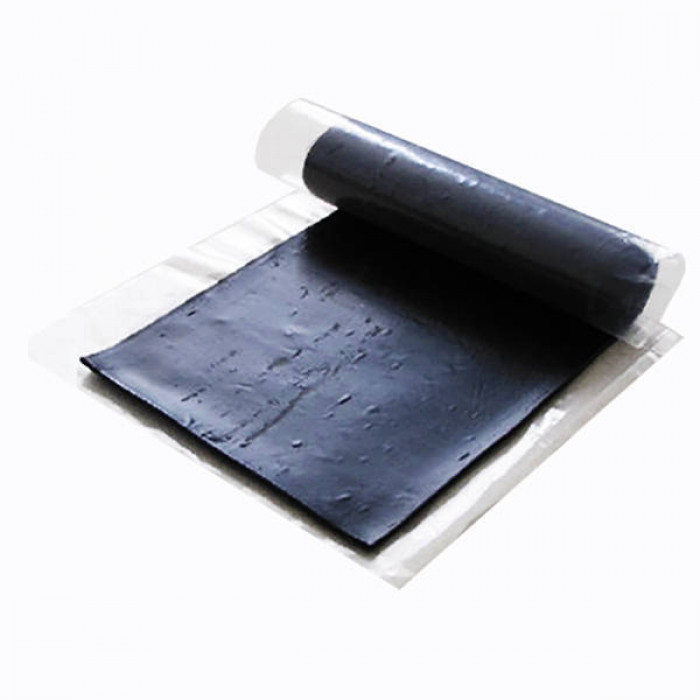

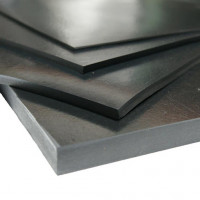

The finished rubber mixture is an amorphous mass, which is packaged in the form of plates, briquettes, etc., after which it enters the production, where rubber products are made from it.

The main types of rubber compound:

• Rubber unvulcanized;

• Commodity food rubber compound - designed for the manufacture of rubber technical products in contact with food;

• Rubber compound unvulcanized calendered;

• Rubber compound based on fluoroelastomer - designed for the manufacture of parts. Operable in the environment of oils, acids, alkalis, hydrogen sulfide.

You can buy Rubber compound 7v 14 from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.