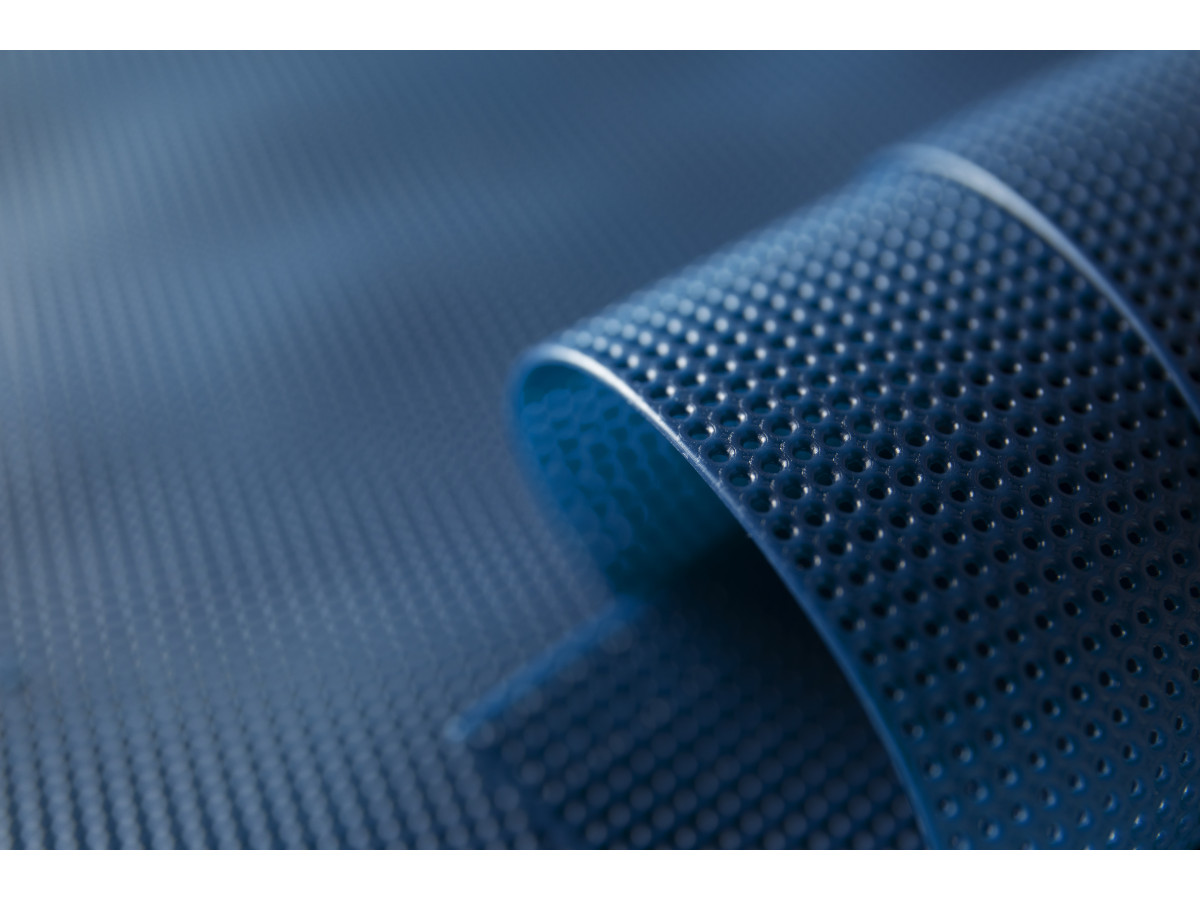

To move liquids and gases over long distances, pipelines are constructed from steel pipes, but due to their lack of flexibility, elements from other materials are required for connection at the end points of distribution. The most well-known device for consumers of product pumped or contained in cylinders and containers is rubber sleeve, colloquially called a hose.

It is capable of bending at significant angles along its entire length, forming an intricate trajectory after bypassing all obstacles and continuously changing it without any consequences for itself. To damage its integrity, a much greater threat is posed by the internal pressure of the working medium exceeding the permissible limit and the loss of elasticity due to excessive drying that occurs under the influence of various factors, leading to brittleness. To combat the first factor, reinforcing elements made of threads, fabrics or metal meshes are introduced into the design, and the second is leveled by introducing special additives into the composition of the feedstock and following simple operating rules. The rubber hose can be used both for regular watering of flower beds and vegetable beds, and for the manufacture of parts of welding equipment and hydraulic systems that operate under significant loads.

Scope of application of rubber hoses and hoses made of other materials

There are many products similar in purpose, but used in other areas. For example, silicone sleeve for shafts Most often it is used, as the name suggests, for rubber coating of rotating parts of various units, although it can also be used for pumping thick masses such as concrete, cement mortar, and bulk materials. Among them there are both specific ones, intended for a single purpose, and more universal ones.

Fire hose

In ancient times, fires were considered almost the most terrible disaster, entailing truly catastrophic consequences. Since wooden buildings were the most common type of residential and commercial buildings, it often happened that entire cities were destroyed by fire. Modern buildings are most often made of brick, reinforced concrete or metal, but the difficulties of fighting fire cannot be completely avoided. Quite strict fire safety rules oblige the administration of public institutions and industrial enterprises to have flame-extinguishing equipment always ready for use, and its manufacturers never stop working on its improvement. A mandatory attribute for equipping specially designated places for storing necessary things is fire hose, intended for connection to the water supply pipeline.

It is assigned specific functions, the successful implementation of which requires some special properties. Here are the main ones:

- The hose must be tightly wound into a coil of as small a diameter as possible, which requires minimizing the thickness of its wall. In addition, this approach provides sufficient flexibility to effectively solve the problems facing firefighters.

- So that the refined material can withstand significant pressure of the liquid moving inside, there is a strong shell on the outside made of rough fabric that is not capable of supporting combustion, and does not at all interfere with free bending.

- When every second counts, the speed of each individual operation is very important. The design is thought out so that both deployment and connection occur as quickly as possible.

Certified products meet all standard requirements and will not cause the slightest claims from regulatory authorities.

PVC sleeve

Polyvinyl chloride is one of the cheapest materials for the manufacture of various products. For this reason PVC sleeve has gained wide popularity and is used to solve many problems. Here are some examples of practical application:

- creation of a protective casing when laying power cables of household and industrial networks in open atmosphere and ground conditions;

- use as a starting material for the production of plumbing equipment, for example flexible elements for connecting sewer units;

- creation of low-pressure air ducts.

Suppliers provide the market with a wide range of modern rubber products. A wide selection of both the technical and operational capabilities of the raw materials, as well as the geometric shape and size allows you to choose the best option for successfully solving most problems at minimal budget costs.