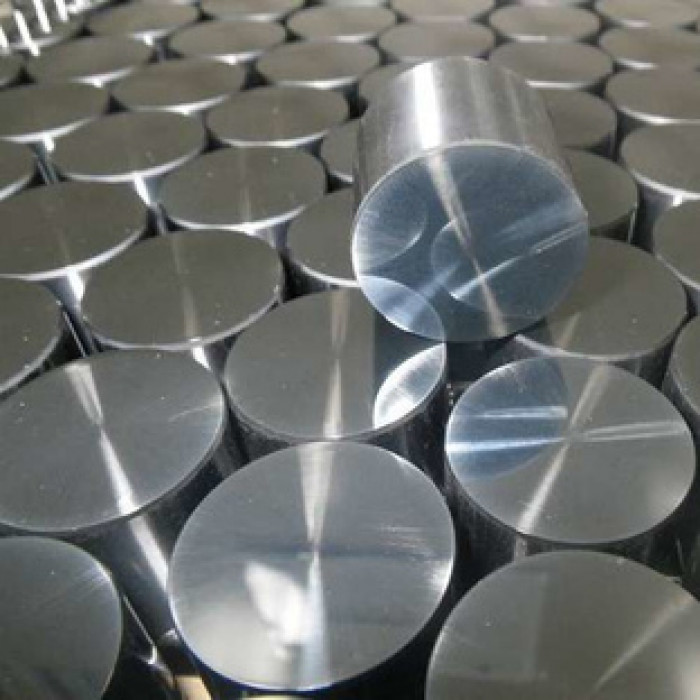

Stainless steel forging st.08Х18Н10Т 280 mm - linear metal-roll of round section without cavities inside. We sell forgings of various assortments, made of specialized complex alloyed steel grades:

12X18H10T, quality, corresponding to GOST 5632−72. Analogue - austenitic steel AISI 321 regulated by ASTM A480.

12X13 according to GOST 5632-72. Ferrite type substitute - AISI 420 per ASTM A240.

30X13 corresponding to GOST 5949−75. Analogue - martensitic alloy AISI 420F.

40X13. Martensitic steel, corresponding to GOST 5949-75, GOST 5632-72, and having a substitute for European quality - AISI 420 according to ASTM A240. Forging 12X18H10T - a blank used for the manufacture of parts:

in the field of mechanical engineering - components for carburetors;

in heat and power production - parts for boiler equipment and compressors;

in the construction industry - measuring and cutting devices;

in the food and chemical industry - parts for industrial equipment;

chemical and wine industry.

Forging, in fact, is a blank. And the scope of its application will also depend on the grade of steel from which it is made. Forging 12X18H10T according to GOST 25054-81 TU 14-1-1-1530-75, GOST 5949-75, GOST 5632-72 is an ideal material for the manufacture of parts for welding machines and other equipment. Provided that they will work at pressure and temperature in the range of -196 - + 500 ° C, and in dilute acidic and alkaline media at a temperature not exceeding + 350 ° C.

Forging is understood as products made from heat-resistant structural stainless steel. Production is carried out by hot stamping or forging. Increased requirements are imposed on the quality of these items, since the parts are used in processes that involve very strong mechanical and thermal effects.

That is why they are used in industries where wear resistance is essential, such as the nuclear power industry and the steel industry. It is no secret that the use of low quality parts in these areas is not only inefficient, but also dangerous.

Due to the high demand for this product in many branches of modern industry, there are separate types of forgings that are designed for use in specific processes.

According to the manufacturing method, forgings are divided into only two types - forging and stamping. Products created by forging are much more durable, which is why they are more expensive, and the production process is longer and more complicated. But stamped forgings are produced quickly and in large quantities. In terms of resistance to mechanical stress, they are slightly inferior to forged ones, however, for solving some problems, high strength indicators are not required. The use of stamping production allows customers to reduce costs and provide them with the right amount of goods in a short time.

Steel forgings are characterized by increased wear resistance of the material and impact load.

During metal processing, waste is minimized, and this provides unlimited opportunities to save on material.

It should be noted that the process of processing the product is simple, and mainly consists of polishing and grinding the surface.

In the construction industry, steel forgings are widely used to create clamps, staples, anchors, as well as fences, supports, metal structures, and so on.

Applications for forgings

Great consumer demand for products of this range is also observed in the engineering industry.

Raw materials are used in the manufacture of elements of gears, gears, rings, bearings, shafts.

In the energy industry, forged steel is used to create rotors, compressors, shafts, cylinders, and much more.

The forging process goes through the following steps:

1. Cutting of rolled products of various configurations to the required dimensions.

Used rolled products can have round, square, rectangular and polygonal sections. Sometimes it is allowed to use a blank in the form of a special profile (corner, I-beam, channel)

2. The process of metal deformation.

3. Heat treatment of forgings (normalization and tempering)

4. Acceptance of the finished forging by the technical control department.

Methods used to make forgings

Today, there are two main methods for obtaining a forging:

• Forging is a process of deformation of a metal billet, which is in a plastic state, and giving it the desired shape by impact loading of hammer or press heads. Forging also includes bending, drawing, drawing. A distinctive feature of forging is that the workpiece is in a free position during the deformation process, it does not have a clear base.

The allowance for processing a forged forging is almost 2 times greater than that of a forging obtained by stamping. In production, forging is used only in small-scale and single-piece production by two main methods, it is manual or machine.

• Stamping - the process of deformation of a metal initial workpiece under pressure, proceeding with the use ofadditional equipment (special stamp). The process of plastic deformation is carried out in the die matrix, the shape of which is completely identical to the forging being produced. The impact element that exerts the load is the punch.

Stamping can be performed with or without preheating of the original workpiece.

Stamping, in contrast to forging, has a fairly high productivity, it does not require highly skilled workers, and at the output, the forging has a higher dimensional accuracy and a low surface layer roughness. However, the use of stamps is advisable only in mass and serial production in order to justify the cost of their expensive production.

Forging 12x18n10t

A forging of this type is a blank for subsequent processing in production. Depending on what grade the forging was made of, the destination area and production restrictions will be determined.

Features of forging 12x18n10t:

This forging is produced in accordance with the established standard GOST and TU.

The scope of application is limiting: the production of equipment and the creation of welding machines.

It can also be used to create components that will be constantly subjected to stress, mechanical damage, shock loading, while the force indicators will be minimal.

Forgings are produced by stamping. Technological equipment is installed in the production, which produces serial production of blanks with further processing to create products from the material. The choice of forging production technology is determined depending on the type of steel, as well as the requirements for the final parts.

You can buy Stainless steel forging st.08Х18Н10Т 280 mm from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.