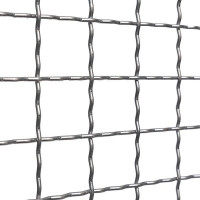

Grid sleeve stainless corrugated RSPG-100-030 NZh is a component for mesh fenders in technological apparatuses, flame arresters, filters, and is used as a nozzle.

The grid is designed for separating the entrained liquid from the steam (gas) flow in distillation, adsorption, stripping and other column apparatus, as well as separators, scrubbers, dust collectors, filters, dryers and many other devices.

Sleeve mesh (mesh sleeve)SRP mesh (mesh sleeve) is produced by the method of smooth, weaving without a longitudinal seam (in the form of a sleeve). Unlike woven fabrics, woven mesh consists of a uniform and continuous series of loops that are intertwined on a tubular shape. The hinges in the mesh are extremely resistant to compression and tension loads. Each loop is free to move in three directions, thus providing a two-way stretch. The loop alone also acts as a small spring when subjected to stress or compression and immediately returns to its original shape when the stress is removed. Thus, this leads to unusual flexibility and resilience of the finished mesh.

The main advantages of using a mesh are that it can be used where the filter material must be extremely stable after exposure to aggressive loads. Confident corrosion resistance, mechanical and thermal shocks, elasticity, resistance to high vibration and high temperatures, resistance to destructive gases, dirty, oily and other extreme conditions - this is not a complete list of the advantages of woven mesh.

The sleeve mesh is made without a longitudinal seam by a slick smooth weaving.

Hose mesh (mesh sleeve) is a separation material and component for mesh fenders, demisters, coalescers, drop eliminators and drop eliminators.

If the goods are manufactured in accordance with TU 26-02-354-85, 26-02-1172-96, then the goods must be packed and marked on each roll

Packing: in accordance with the specifications, each roll (bay) is wrapped in paraffin paper according to GOST 9569 or bituminous or tar packing paper and tied with twine. Several mesh ends cannot be included in a roll or coil, i.e. The roll is supplied in one sleeve.

Mesh sleeve is used for

mesh fenders of technological devices

separation of the entrained liquid from the steam/gas flow in distillation

in the design of devices where it is necessary to clean from smoke and dust

absorption, stripping and other columns, separators, scrubbers, filters

Applications

metallurgical

chemical

oil and gas production

oil and gas processing

petrochemical

The following materials can be used to create this product:

low-carbon steel galvanized

high alloy steel

one of the non-ferrous metals

various non-ferrous metal alloys that meet the required specifications

In the production of a sleeve mesh, a smooth knitting method is used. The sleeve can have both a flat surface and a corrugated one. Knitting mesh is carried out using a round or flattened wire. One of the main characteristics of this type of product is the number of loops made on a length of 55 mm. Width is also an important parameter. An important role is played by the diameter of the wire used for the production of the sleeve. If the mesh sleeve is corrugated, then its main properties are considered to be the height, as well as the distance between the corrugations.

Representatives of different types of industry often want to order a mesh sleeve. Products are in demand both in the metallurgical and chemical, and in the gas and oil fields of activity. The mesh sleeve is often used as one of the components for the fenders of technological units. It is used in adsorption and other column apparatuses, since it separates the entrained liquid. Often a mesh sleeve can be used in various separators, as well as in scrubbers in the oil and gas processing industry. This product is also used in devices where it is necessary to clean the smoke. Sleeve mesh can also be used to create any household products. This includes a variety of metal scrapers or washcloths, which are designed to clean certain surfaces from adhering dirt. A big plus of the sleeve mesh is its high strength and resistance to various weather conditions. Due to this, the service life of this product is quite large.

Stainless mesh sleeve, which is also called sleeve mesh, is made of corrosion-resistant steel wire grade 12X18H10T according to GOST 18143-72 with a cross section of 0.3 mm.

Mesh sleeve, braided from stainless steel wire, is an accessory for fenders, filters designed to separate the entrained liquid from the vapor (gas) flow in distillation, adsorption, stripping and other column apparatuses, andalso gas separators and scrubbers of gas producing, oil refining and other industries.

Examples of symbolic designation of a mesh sleeve: RS-0.3; RS-12X18H10T; sleeve mesh; SR-0.3x90 mm; mesh wire woven sleeve; nozzle mesh sleeve; NSR-0.3. We also supply corrugated mesh sleeves.

Mesh corrugated sleeve RSG-0.3mm st. , oil refining, gas production, gas processing, petrochemical, metallurgical and other related industries.

Sleeve mesh corrugated RSG is made of stainless steel wire grade 12X18H10T in accordance with GOST 18143-72.

Examples of possible designation of a corrugated mesh sleeve: RSG-12X18N10T 0.3x80mm, RSG-0.3 TU 26-02-1099-89, corrugated mesh sleeve nozzle, NSRG, corrugated mesh braided sleeve RSPG.

You can buy stainless steel mesh from us at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.