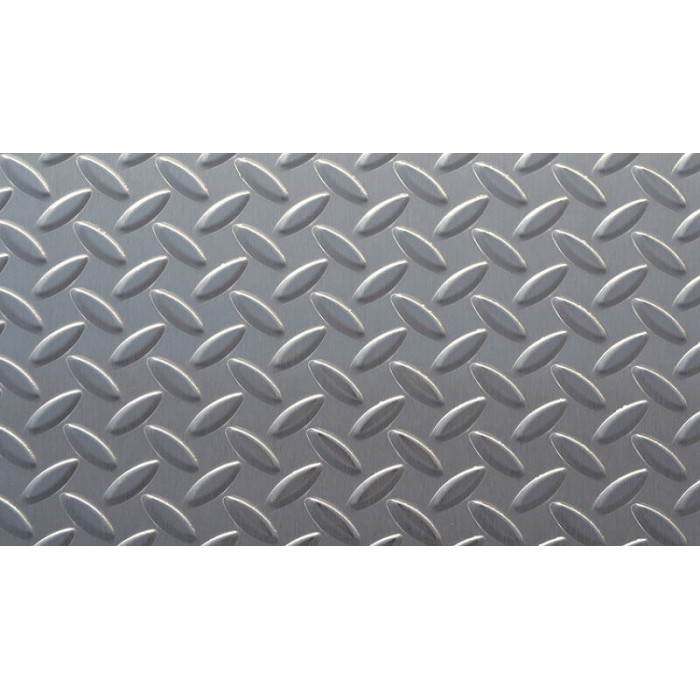

Corrugated stainless steel sheet 1 mm is a stainless metal-roll with convex elements applied along the entire length of the sheet - corrugation. Depending on the shape of the pattern, the following types of corrugation are distinguished: lentil, rhombus. The lentil pattern stainless steel sheet in our catalog consists of a single set of corrugations arranged at right angles. Stainless steel with this corrugation is in great demand among buyers. Therefore, in our warehouse there is always a corrugated lentil sheet of different sizes. Stainless steel is highly resistant to rust, strong and durable. The convex pattern provides anti-slip properties and safe operation.

AISI 304 grade (Analogue according to GOST: AISI 304 - 08X18H10, AISI 304 L - 03X18H11) is one of the main grades of stainless steel. It has high formability, corrosion resistance, strength and high mechanical performance. Chromium is the main element of steel, which determines its resistance to oxidation (corrosion). This steel has excellent low temperature properties.

The manufacturing accuracy of stainless corrugated sheets can be high or normal. The thickness of rolled metal is determined in millimeters by the height of the base without taking into account the height of the bulges. Corrugated sheet lentils are produced with a distance between corrugations of 20, 25 and 30 mm. The height of the corrugation is in the range of 0.1-0.3 base thicknesses, but not less than 0.5 mm.

What is corrugated sheet? This is a kind of flat steel. Unlike smooth sheet steel, it has three-dimensional elements (grooves) on one side. This feature makes the rolled surface volume-textured, and due to the variable cross section, the metal consumption of the product is reduced. The diagonally oriented arrangement of corrugated elements also: increases the wear resistance of the rolled surface; increases resistance to static and dynamic loads; provides reliable grip and excellent anti-slip effect. The nature of the corrugation determines the stress-strain state of the metal in the deformation zone and the actual contact surface. Rhombic and lentil corrugation are the two main corrugation schemes in accordance with the standards of Ukraine and the CIS. The latter is characterized by the absence of a closed loop and therefore such rolled products are less prone to clogging and accumulation of moisture and snow, which determines its wider application. In the conditions of the modern market, in the catalogs you can find a corrugated sheet of metal with various configurations and arrangements of the corrugations. As a rule, such products are made of aluminum and thin sheets of carbon, low alloy and stainless steel. Corrugated steel sheet production Corrugated steel is a product of hot rolling. The dimensions of the initial workpiece are set the same as in the production of smooth rolled products of comparable thicknesses. The quality indicators of slabs must correspond to the internal conditions of the plant. They should not be captured, shells, cracks and flaws from burns. The technology of heating a semi-finished product before rolling and corrugating does not differ significantly from the usually established modes of heating steel before redistribution. The only general rule is to heat the slab before rolling to the upper limit of the specified temperature range for each specific steel grade (this allows for the maximum rolling temperature in the last pass, in which the corrugation is performed with limiting force). Then the billet, heated to a certain temperature, is passed through the stands of a wide-strip mill, where the lower roll is smooth, and rhombic or lentil grooves are applied to the surface of the upper one (the elements of the corrugation are located at an angle of 45 degrees to the rolling direction). To increase the height of the corrugation, increase the absolute compression. The simplest technological operation is corrugation in one roll pass in the stand. After cooling, the rolled products are straightened and cut on guillotine shears. If necessary, products can be subjected to additional operations - heat treatment (annealing, normalization or tempering), pickling, shot blasting and coloring. Also, significant differences in the types of corrugation and the purpose of corrugated sheet steel are determined by the variety of technological methods that have to be resorted to for organizing industrial production. Types of corrugated steel sheet Modern ferrous metallurgy produces rolled steel sheets with various corrugation configurations. Accordingly, the types of such metal products have both similar and distinctive properties. Corrugated sheet "rhombus" - rolled metal with a rhombic corrugation protruding above the main surface - is, as a rule, a product for general use. And, with rare exceptions, for a long time it was produced and supplied in accordance with GOST 8568. Today in Ukraine this standard has been replaced by DSTU 8783. It is also worth noting that GOST 8568/DSTU 8783 his mechanicsPhysical properties are not regulated and mechanical tests for finished products are not carried out. Corrugated steel sheet for responsible and specific purposes is produced according to the technical specifications (TU) and enterprise standards (STP), developed and approved by each manufacturer in the prescribed manner.

Such sheets are used in the industrial sector and the construction industry. Their functional surface is characterized by a certain convex pattern, which consists of several unified elements. Each of them is a separate corrugation. If the texture of the product has five grooves, the sheet is called a quintet, two - a duet, one - a lentil.

Different blocks of the pattern in relation to each other are placed at a given angle. The shape of the corrugation can be rhombic or oval. The thickness of the described stainless sheets varies between 0.5–3 mm. Note that the inner side of the corrugated products does not have any special protrusions, it is absolutely smooth. The main operational advantages of the stainless steel products under consideration are as follows:

immunity to temperature changes;

resistance to aggressive chemical compounds;

durability of use and the invariance of the initial technical and purely external properties;

resistance to oxidation;

high strength and anti-corrosion characteristics.

Corrugated stainless steel is often used for the manufacture of floor anti-slip coatings mounted inside various premises and outdoors. The patterned surface of the sheets guarantees absolute safety of movement on them. Also corrugated products are literally indispensable for:

lining (outside and inside) of all kinds of rooms in which the release of certain chemical compounds is noted;

manufacturing of parts and structures in the machine-building and chemical industries;

Corrugated stainless steel sheet, due to its exceptional resistance to corrosion, is especially in demand in the field of production of frame structures operated in the sea or ocean. Due to their high heat resistance, these products are also in demand in the manufacture of outdoor fire escapes of buildings and emergency exit equipment.

The stainless steel corrugated sheet pattern is a 90 degree set of corrugations that can consist of one (Lentil), two (Duet) and five (Quintet) elements. Depending on the thickness of the stainless sheet and the type of corrugation, the optimal area for its use is determined. This rolled metal is sold both in sheets and in rolls, which greatly simplifies transportation and storage. Anti-slip stainless steel sheet with a notch is a unique metal product with high practical properties that allows you to successfully solve specialized tasks in various projects.

Rolled steel with a corrugated surface is made from carbon steels of ordinary quality. As a rule, these are grades St1kp, St1ps, St2ps, St2sp St3kp, St3ps, St3sp, smelted in accordance with the requirements of DSTU 2651 / GOST 380. Other steels for the production of corrugated rolled products (08kp, 08ps, 20, S235JR, 09G2S, S235, etc. ) are used as agreed between the customer and the manufacturer. According to the quality of rolling, such metal is classified into high-precision (A) and normal (B) precision rolled products. The main assortment characteristics of corrugated sheet metal for general and industrial purposes are overall dimensions, pitch and corrugation height. Dimensions in length and width, the maximum allowable deviations in these parameters are taken in accordance with DSTU 8540 and GOST 19903. Taking into account the variable thickness of the section, the base thickness is considered the main parameter for rolled metal with corrugation. The height of the corrugation is 0.1 ... 0.3 of the thickness of the base, but at the same time it cannot be less than 0.5 mm.

The operational properties of rolled products with corrugation are determined primarily by the chemical composition of the steel grade used. But in general, these metal products are characterized by: sufficient resistance of the surface to abrasion; good primer and paint retention; good decoration; weldability; affordable cost; high manufacturability in processing; no reflective effect under intense lighting. Sheet metal with corrugation is an economical type of metal products. Possessing an optimal ratio of characteristics, it is characterized by low metal consumption, so its use helps to reduce metal consumption and increase the profitability of ongoing projects.

Corrugated stainless steel sheet 1 mm is indispensable in the production of various containers, tanks, containers, receivers and other industrial equipment. In construction, it is mainly used for the production of various types of pipes. In the chemical industry, this type of steel is used for the production of equipment for the transportation and storage of reagents. In the food industry, AISI 304 steel is an integral part of equipment for the production, storage and transportation of various beverages.(milk, wine, kvass, etc.), in addition, steel is used for the manufacture of kitchen and tableware.

No questions about this product, be the first and ask your question.