Gold coated stainless steel sheet "Checker" 1*2 m, thickness 0.4 mm, AISI 304 coated with titanium nitride (golden color). These coatings are corrosion-resistant to atmospheric influences and absolutely environmentally friendly and are applied by vacuum ion-plasma technology using modern high-tech equipment.

Titanium nitride is a unique material, the coating of which is not inferior in its aesthetic and operational characteristics to gold. It is not subject to corrosion, does not change color, is resistant to atmospheric precipitation, reliable and durable.

Bulatirovanie is a technology of spraying stainless steel with titanium nitride.

The metal subjected to bulking is distinguished by such characteristics necessary in construction as strength and durability, resistance to corrosion and various weather conditions, vandal-resistant. Products from it have a flawless appearance and a diverse range of shades.

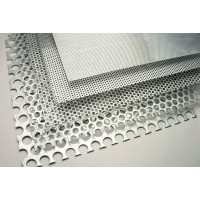

CHECKER ROOFING is not the know-how of craftsmen. This type of coating has been known for a very long time, although it has not become widespread due to the high requirements for the roofer's qualifications. However, scaly roofing was ideal where other materials can only be used with great difficulty. For example, when finishing roofs of complex shape or domes, and in particular - with a low strength of the carrier system, because metal checkers greatly outperform most traditional coatings in terms of weight.

The company sells a roofing checker with the ability to individually assemble a pattern for a roof of any form of complexity. The modern design of the seam combines forgotten ancient technologies with a new design of durable material.

Why was the roof invented with a checker

When the question arises of how to cover a complex-shaped roof, roofing with a checker comes to the rescue. Created material to beautifully build. The revived know-how of old folk craftsmen is indispensable on roofs where the supporting system is not strong enough, there are domes and other complex structures. It is convenient to use seam scales when it is difficult or impossible to lay sheet roofing materials.

Varieties of scales

The shape of the scales is made by a rectangle, a rhombus. After laying, rows are formed in the form of symmetrical diamonds. Scales may differ in execution, but they are all divided into two types: the shape of a smooth and voluminous checker.

Pros and cons of checkered roofing

In an unusual modern design, checkered roofing is just beginning to come into fashion. Among the main advantages are:

beauty, individual roof design;

the possibility of laying on a truss system of complex shape with weak bearing capacity;

Self-tapping screws are not required for mounting the roof with a checker.

Compared to metal tiles and corrugated board, scales are more difficult to install. The cost of 1 m2 of finished roofing is more expensive, which is considered a lack of material.

Where can roofing sheets be installed?

Scaled roofing is suitable for all types of pitched roofs. Rectangles and rhombuses are produced in different sizes, which allows you to choose elements for spiers, towers, domes. Scales can cover part of a complex roof, matching in color to the main sheet metal roof. Checkers are suitable for finishing the facade of the building, false roofing.

What materials are used to make scales

Budget option - elements made of galvanized steel with a polymer coating. For the manufacture of durable rhombuses, copper, stainless steel, aluminum and titanium-zinc alloys are used. Colors correspond to the RAL system.

Here you can buy a stainless steel sheet coated with gold "Checker" 1 * 2 m, thickness 0.4 mm, AISI 304 at the best price in Ukraine. A wide range of products allows us to quickly and efficiently fulfill any order, helping to complete any construction work on time.

No questions about this product, be the first and ask your question.