Brovary electrical steel transformer 3413, dynamo 2212, cutting and delivery

Electrical steel, also called dynamo steel, transformer steel, silicon electrical steel - an alloy of iron, usually with silicon, sometimes alloyed with aluminum, the finished product is produced in the form of thin sheets with a thickness of 0.05 to 2 mm.

Magnetically soft ferromagnetic material. It has improved ferromagnetic properties for use in alternating magnetic fields.

It is used in the manufacture of magnetic circuits for various electrical equipment - electromagnets, transformers, generators, electric motors, chokes, relay magnetic circuits, ferroresonant voltage stabilizers, etc.

Properties

Depending on the required properties, electrical steel contains different amounts of silicon. Depending on the production technology, electrical steels are divided into cold-rolled (isotropic or anisotropic; the amount of silicon is up to 3.3%) and hot-rolled (isotropic; the amount of silicon is up to 4.5%). Often, aluminum can be contained as an alloying additive in electrical steel (up to 0.5%). Sometimes electrical steels are conditionally divided into dynamo (isotropic), transformer (anisotropic), relay (isotropic, unalloyed).

Electromagnetic properties

As a rule, electrical steels try to perform:

with the highest possible magnetic permeability;

with as low coercivity as possible and with a narrow hysteresis loop.

with a possibly higher electrical resistivity to reduce core heating losses due to the effect of eddy currents [1] [non-authoritative source].

The relative magnetic permeability μ/μ0 of electrical steel strongly depends on the magnitude of the applied field. For example, electrotechnical sulfur steel E43 in weak fields has μ / μ0 = 600-1000, in medium fields - up to 11000. [2]

Production

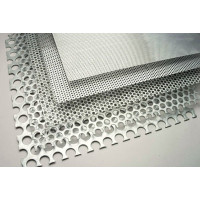

Electrical steel is produced in the form of sheets (often in rolls) and a narrow strip 0.05–1 mm thick. The quality of electrical steel is characterized by electromagnetic properties (specific losses, coercive force and induction), isotropy of properties (difference in the values of metal properties along and across the rolling direction), geometric dimensions and quality of sheets and strips, mechanical properties, and coating parameters. The decrease in specific losses in steel ensures a decrease in energy losses, and an increase in the maximum induction of steel makes it possible to reduce the dimensions, a decrease in the anisotropy of properties improves the characteristics of devices with a rotating magnetic circuit. Electrical steel is usually supplied in an annealed condition. To relieve mechanical stresses arising in the manufacture of parts, an additional short-term annealing is carried out at 800–850°C. Some electrical steels are supplied unannealed; in this case, to ensure a given level of properties after machining, it is necessary to carry out heat treatment of parts.

Coercive force A characteristic of the possibility of a force field created by an electric current to demagnetize. This is the magnetic field strength on the static limiting hysteresis loop, at which there is no induction in the metal. It is measured in amperes per meter. The ETS has a small coercive force, as well as hysteresis losses. The intensity of demagnetization varies depending on the type of devices. Silicon as an additive increases the specific resistance of the ETS, reduces hysteresis losses, which leads to a decrease in the coercive force. When the Si ratio ≥5%, there is a sharp increase in hardness and brittleness, which makes transformer iron unsuitable for stamping. Electrical resistivity The parameter characterizes the ability of a metal to resist the passage of an electric current. Depends directly on the percentage of silicon - the element weakens the aging of steel. The resistance increases with increasing temperature. The larger the proportion of Si, the higher the average R, the lower the eddy current losses. The use of ETS allows the electrical intensity to be concentrated inside the conductor and ensure the targeted delivery of electrical charges to the end point of the distribution. Therefore, electrical steel for electric motors is used in the manufacture of their main parts in EMF with a frequency of up to 20,000 Hz. Types of electrical steel ETS is supplied both with an unprotected top layer and with an insulating coating. Although electrical steel does not have a clear “recipe” in terms of chemical composition, the mass fraction of the fundamental element - Si or the Si + Al compound (at the level of 0.5%) - divides it into categories: transformer - alloying degree 3.0-4.5% ; dynamic - 0.8-2.5%. Another factor that determines the properties of materials is the internal structure, the size of the cells. Here lies the fundamental difference between cold and hot rolled alloys. Heat treatment and mechanical influences help to achieve the desired grain size. hoveredDepending on the type of production and the level of magnetic properties, there are: high-permeability transformer steel - with B800 (rectifying annealing) ≥ 1.90 (T); increased permeability - 1.85 T ≤ B800 ≤ 1.89 (T); limited permeability - B800 ≤ 1.85 (T).

What quality indicators characterize electrical steels and alloys? The following factors influence the properties of the metal: geometrical parameters; specific losses; induction; coercive force; isotropy; coating characteristics. Electrical steels and alloys have a characteristic feature: they make it possible to reduce resistance and, as a result, reduce energy consumption for sending electrical signals. Geometric dimensions In addition to the chemical composition, the properties of the metal are affected by the physical and crystallographic parameters of the sheet. They are formed in the process of multi-stage mechanical and heat treatment during the redistribution of the workpiece into plates. Rolled products from ETS are standardized according to the following parameters: transverse and longitudinal thickness variation; limit deviations in thickness and width; maximum burr height; flatness. The geometry of the transverse profile of the strips after hot rolling affects the tensile stresses in the sheet and the probability of their breakage. Features of electrical insulating coating Electrical insulating coating (EIP) on a steel strip is one of the main requirements of consumers. The composition of the EIP contributes to the formation of tensile forces between the metal and the insulation itself, which reduces the specific losses by 1.5-2 W/kg. Cold-rolled anisotropic steel can be without an electrical insulating coating or with a heat-resistant coating that does not complicate stamping, and with a soft one.

Isotropic and anisotropic steel - production differences

As can be understood from the above, the characteristics of the doped compound are highly dependent on the silicon content. The second factor that determines the properties of the metal is its internal structure, which is formed during the production process. In particular, hot-rolled and cold-rolled steels have different cell sizes. Coarse-crystalline materials are characterized by large values of magnetic permeability, but the coercive force is significantly lower than that of metals with a fine-grained structure. Two types of processing allow varying the grain size: mechanical and thermal.

So annealing of steel contributes to a decrease in internal stresses in the metal, while at the same time leading to an increase in the crystals that form its structure. Hot rolling of electrical steel is unable to create a stable grain orientation within the metal, leaving it chaotic. Such an isotropic steel, as a result, is characterized by independence of magnetic properties from direction.

To achieve a textured structure with a certain spatial orientation of crystals in the metal allows repeated cold rolling of steel, accompanied by annealing under special conditions. As a result, an anisotropic steel is obtained, where the edges of the cubic lattice of crystals are installed in the direction of rolling. By positioning anisotropic steel in the correct direction, one can achieve an increase in magnetic permeability while simultaneously reducing the coercive force.

The production of electrical steel has been established in the form of flat products with a strip width of 240 - 1000 mm. The metal is produced in rolls or individual sheets, the length of which varies from 720 to 2000 mm. The thickness of the electrical steel profile starts from 0.05 mm and can have the following values: 0.1, 0.2, 0.35, 0.5 and 1.0 mm. In addition, the classification of electrical steels by product type allows the following types of rolled products: sectional and cut strip.

Properties of electrical steel

The value of silicon-doped iron is due to its improved electromagnetic characteristics: a high level of saturation induction, minimization of hysteresis losses, and reduced coercive force. Since the anisotropic structure allows further improvement of these properties, the demand for non-textured steels is initially higher.

The question, for what purposes electrical steels are used, finds the answer in the name of the metal. One of the purposes of the alloy is cores in such devices:

current transformers;

stators and rotors of electrical equipment;

power transformers.

In addition, electrical steel is an excellent material for magnetic circuits in electrical apparatus. It is not difficult to understand why the core of a transformer is made of electrical steel. This follows from the properties of the metal, in particular, the increase in electrical resistivity. This, in turn, leads to a reduction in power losses from eddy currents characteristic of the transformer core. As a result, the overall efficiency of the device increases, and the core itself heats up less.

Even more to level losses from eddy currents, it is possible to reduce the thickness of the plates. Therefore, electrical steel for electric motors, in particular transformer cores, must have a thickness of 0.5 mm at a frequency of 50 Hz. If the current source operates at largethicker sheets of electrical steel are used under the core: 0.1 or 0.2 mm.

Additional energy losses in the transformer core occur due to hysteresis - the process of cyclic magnetization reversal. To narrow the hysteresis loop, respectively, to reduce its area will lead to a decrease in losses due to magnetization reversal. This is the second reason for using electrical steel in the core of a transformer.

Since the reduction of eddy current losses and hysteresis is achieved by increasing the silicon content in the metal, the alloy with a high concentration of Si is called transformer steel, the characteristics of which are better tuned specifically for transformers. In terms of numbers, in the production of high-power transformers, the use of grain-oriented steel can reduce losses by a third. In addition, this helps to reduce the weight of the transformer by 10% and the consumption of the metal itself by 20%.

In addition to transformers, electrical steel, depending on the grade, is used for:

magnetic circuits in the manufacture of electrical equipment - grade 2212, sulfur isotropic, ARMKO 20895/20880;

electric motors and similar products - brand 10895/E12/ARMKO;

other electrical products - brand 10880/E10/ARMCO.

No questions about this product, be the first and ask your question.