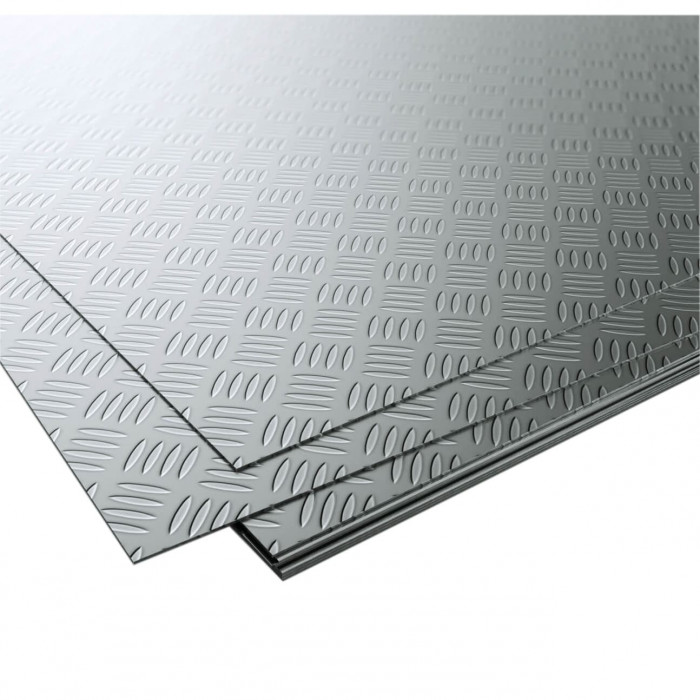

Brovary stainless corrugated sheet 08X18H10T AISI304, corrugated sheet, quintet, rhombus

Corrugated sheet is a kind of flat steel. Unlike smooth sheet steel, it has three-dimensional elements (grooves) on one side. This feature makes the rolled surface volume-textured, and due to the variable cross section, the metal consumption of the product is reduced. The diagonally oriented arrangement of corrugated elements also: increases the wear resistance of the rolled surface; increases resistance to static and dynamic loads; provides reliable grip and excellent anti-slip effect. The nature of the corrugation determines the stress-strain state of the metal in the deformation zone and the actual contact surface. Rhombic and lentil corrugation are the two main corrugation schemes in accordance with the standards of Ukraine and the CIS. The latter is characterized by the absence of a closed loop and therefore such rolled products are less prone to clogging and accumulation of moisture and snow, which determines its wider application. In the conditions of the modern market, in the catalogs you can find a corrugated sheet of metal with various configurations and arrangements of the corrugations. As a rule, such products are made of aluminum and thin sheets of carbon, low alloy and stainless steel. Corrugated steel sheet production Corrugated steel is a product of hot rolling. The dimensions of the initial workpiece are set the same as in the production of smooth rolled products of comparable thicknesses. The quality indicators of slabs must correspond to the internal conditions of the plant. They should not be captured, shells, cracks and flaws from burns. The technology of heating a semi-finished product before rolling and corrugating does not differ significantly from the usually established modes of heating steel before redistribution. The only general rule is to heat the slab before rolling to the upper limit of the specified temperature range for each specific steel grade (this allows for the maximum rolling temperature in the last pass, in which the corrugation is performed with limiting force). Then the billet, heated to a certain temperature, is passed through the stands of a wide-strip mill, where the lower roll is smooth, and rhombic or lentil grooves are applied to the surface of the upper one (the elements of the corrugation are located at an angle of 45 degrees to the rolling direction). To increase the height of the corrugation, increase the absolute compression. The simplest technological operation is corrugation in one roll pass in the stand. After cooling, the rolled products are straightened and cut on guillotine shears. If necessary, products can be subjected to additional operations - heat treatment (annealing, normalization or tempering), pickling, shot blasting and coloring. Also, significant differences in the types of corrugation and the purpose of corrugated steel sheet are determined by the variety of technological methods that have to be resorted to for organizing industrial production. Types of corrugated steel sheet Modern ferrous metallurgy produces rolled steel sheets with various corrugation configurations. Accordingly, the types of such metal products have both similar and distinctive properties. Corrugated sheet "rhombus" - rolled metal with a rhombic corrugation protruding above the main surface - is, as a rule, a product for general use. And, with rare exceptions, for a long time it was produced and supplied in accordance with GOST 8568. Today in Ukraine this standard has been replaced by DSTU 8783. It is also worth noting that GOST 8568/DSTU 8783 its mechanical properties are not regulated and mechanical tests for finished products are not carried out. Corrugated steel sheet for responsible and specific purposes is produced according to the technical specifications (TU) and enterprise standards (STP), developed and approved by each manufacturer in the prescribed manner. Steel sheet with rhombic corrugation With such a corrugation scheme, three-dimensional rhombuses with a depressed middle are formed on the surface of flat rolled products. The angle at the top of the corrugation is 28 degrees (permissible tolerances are ±2 degrees), the profile diagonal is 25…30 by 60…70 mm. On such a sheet, the corrugation forms a closed contour of the pattern. On the one hand, this increases adhesion to the contact surface, but on the other hand, it provokes increased rusting of the metal due to the accumulation and condensation of moisture in the concave part of the surface and increases the mass of metal products. In addition, at the slightest violation of the technology and speed regime at the intersections of the corrugations, metal tightening (reduction in height) can be noted. Increased labor intensity increases the cost of this product and its production volumes have recently been significantly reduced. Sheet with lentil corrugation The most popular type of rolled products of this type. Elongated oval corrugations are made on its surface, and since it is similar in shape to a legume grain, this product is usedmay be identified as lentil corrugated sheet. If the axes are drawn through the greatest length of the volume-convex elements, it will be seen that they are located at right angles to each other, and the distance between them can be 20, 25 and 30 mm. Today, several metal corrugation schemes are used, there is even corrugated rolled metal that imitates scales. But the main ones are the following schemes, based on the lenticular shape of volumetric-convex elements: "Diamond" - single-placed riffles; "Duet" - a paired arrangement of lentil riffles; "Quartet" and "Quintet" - riffles are grouped into blocks of 4 and 5 pieces, respectively. But the corrugated sheet "lentil", manufactured according to DSTU 8783 / GOST 8568, always has single corrugations. The rest of the products are produced only according to specifications. Assortment of corrugated sheets Rolled steel with a corrugated surface is made from ordinary quality carbon steels. As a rule, these are grades St1kp, St1ps, St2ps, St2sp St3kp, St3ps, St3sp, smelted in accordance with the requirements of DSTU 2651 / GOST 380. Other steels for the production of corrugated rolled products (08kp, 08ps, 20, S235JR, 09G2S, S235, etc. ) are used as agreed between the customer and the manufacturer. According to the quality of rolling, such metal is classified into high-precision (A) and normal (B) precision rolled products. The main assortment characteristics of corrugated sheet metal for general and industrial purposes are overall dimensions, pitch and corrugation height. Dimensions in length and width, the maximum allowable deviations in these parameters are taken in accordance with DSTU 8540 and GOST 19903. Taking into account the variable thickness of the section, the base thickness is considered the main parameter for rolled metal with corrugation. The height of the corrugation is 0.1 ... 0.3 of the thickness of the base, but at the same time it cannot be less than 0.5 mm.

Anti-slip properties make this material in demand at chemical, oil, food industry facilities, in places where slipping from oils and greases is possible.

Often, “grooved” can be found at civil facilities with heavy pedestrian traffic, for example, in the subway, or shopping centers, where sheets are laid near escalators or entrance groups in order to prevent dangerous situations and subsequent injuries.

Corrugated stainless steel sheet is used in the following fields:

production of flights of stairs and flights for various purposes, which, as a rule, are operated in the open air;

use as a floor covering in pools, baths and other premises associated with water procedures;

application for covering walls and floors in production shops of the food and chemical industries;

use in the manufacture of steps for public transport;

application in the production of above-ground transitional bridges;

production of safe fences for highways, construction and production sites;

production of decorative protective elements for radiators;

reinforcement of plaster;

use as hatches and shields for viewing windows and technical wells.

Corrugated stainless steel sheet, due to its exceptional resistance to corrosion, is especially in demand in the field of production of frame structures operated in the sea or ocean. Due to their high heat resistance, these products are also in demand in the manufacture of outdoor fire escapes of buildings and emergency exit equipment.

The stainless steel corrugated sheet pattern is a 90 degree set of corrugations that can consist of one (Lentil), two (Duet) and five (Quintet) elements. Depending on the thickness of the stainless sheet and the type of corrugation, the optimal area for its use is determined. This rolled metal is sold both in sheets and in rolls, which greatly simplifies transportation and storage. Anti-slip stainless steel sheet with a notch is a unique metal product with high practical properties that allows you to successfully solve specialized tasks in various projects.

Advantages of corrugated steel sheet The operational properties of corrugated rolled products are determined primarily by the chemical composition of the steel grade used. But in general, these metal products are characterized by: sufficient resistance of the surface to abrasion; good primer and paint retention; good decoration; weldability; affordable cost; high manufacturability in processing; no reflective effect under intense lighting. Sheet metal with corrugation is an economical type of metal products. Possessing an optimal ratio of characteristics, it is characterized by low metal consumption, so its use helps to reduce metal consumption and increase the profitability of ongoing projects.

Decorative stainless steel - an original solution

The previously described corrugated steel sheets are a kind of decorative corrosion-resistant products. The latter can be safely called unique products. modern decorative sheet(sometimes referred to as decorated) combines a chic appearance with excellent corrosion resistance. It is used for:

creating unusual interior solutions;

when finishing the facades of buildings, elevators, various types of premises;

production of modern promotional products - banners, shop windows.

Also, a decorative sheet is used to decorate various products, ranging from lighting fixtures and furniture, to household appliances, sculptures and fountains. This rental gives the familiar to all designs an original look.

Decorative sheet has many varieties. It happens:

matte and mirror;

ground and polished;

with a special coating.

Decorative stainless steel - an original solution

Decorative frosted sheet

Stainless mirror sheet is used in the production of outdoor advertising, elements of kitchen sets, food equipment, decorative fittings, engineering products. It is used to make floor coverings, crockery and cutlery.

In the latter case, as a rule, a polished sheet is used. Brushed steel products are indispensable in the food industry. They make a wide range of various items. Note that the food sheet is characterized by special properties - heat resistance, strength and environmental friendliness. This is achieved by the fact that such decorative stainless steel has a special composition with a well-chosen content of chemical elements, that is, we are talking about special food grade steel.

Let's say a few words about titanium-coated sheets. These products make it possible to solve the most unusual restoration tasks, they are in demand by architects and interior decorators. A sheet coated with titanium (netrite-titanium) is good for building monuments, erecting domes of temples, making three-dimensional letters, information signs, and any advertising structures.

Types of corrugated sheets

Stainless corrugated sheets are produced with several types of corrugations:

Rhombic - parallel grooves cross the entire plane of the sheet diagonally in two directions at an angle of 45⁰, forming many rhombuses on the surface.

Lentil - Rifles resemble lentils in shape and are located at an angle of 90⁰ to each other at equal distances.

Duet - Rifles are in the form of toothpicks, neatly laid out on a steel sheet in groups (pairs). Each group is located at an angle of 90⁰ to the neighboring group, thus building the original pattern.

Quintet - repeats the form of the Duet, but differs in the number of flutes in each group. Namely, each group contains four riffles. Thus, the pattern is formed much denser than the Duet, which provides a large area of adhesion.

No questions about this product, be the first and ask your question.