Cherkasy lead sheet and roll, ligature of alloys, bronze tape BrB2, bronze plate, bronze casting, bronze strip, ingot OTsS 555, BrAZh 9-4, bushings, round timber (rod), pipe, bronze wire

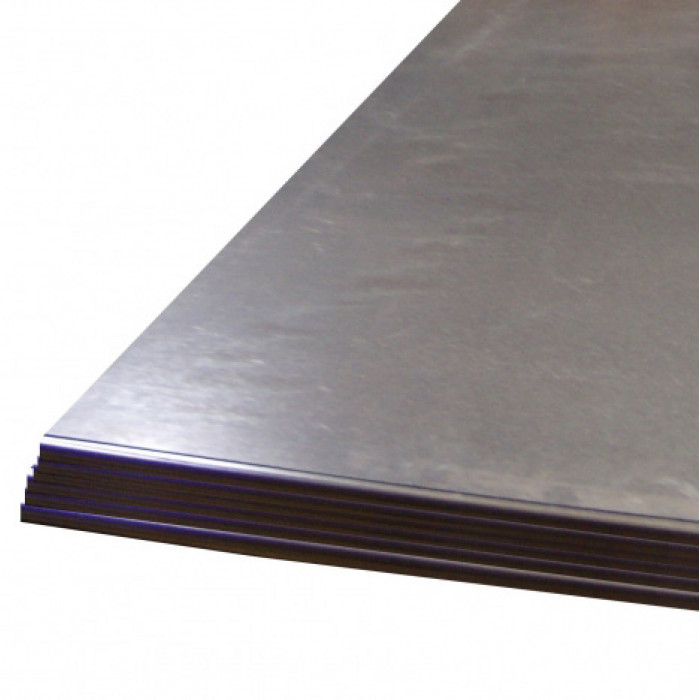

Lead sheet is a rectangular profile made of lead and its alloys, such as lead-antimony (general purpose - SSu, SSu2, SSuZ, SSu8, SSuYu, special purpose - SSuM, CCyMl, SSuM2, SSuMZ, SSuMYu). Arsenic increases the heat resistance of Pb, and nickel increases wear resistance, calcium adds density, and sodium or magnesium gives strength. In an alloy with copper, lead perfectly resists the effects of sulfuric acid, and with cadmium, anti-corrosion properties are improved. Tin will help prevent metal fatigue.

Depending on the range of use, they differ: battery alloys, protective, pigment, general and military purposes.

Lead sheets are made from specially prepared ingots, by high pressure and rolled on special mills. At the final stage, they are hemmed, that is, they are adjusted to the required dimensions. Since sheets from 0.2 to 20 mm from this metal are very soft, durable, strong and, moreover, have radiation protection properties, they are widely used in the nuclear industry and medical institutions for finishing radiography rooms.

In construction, lead sheet has established itself as an excellent sound and waterproofing and roofing material. No chemical current source can do without the use of lead, whether it is a powerful battery or an ordinary battery, and in the chemical industry containers for storing hazardous substances are made from this metal. Hermetic properties allow lead to find application as a protective material for something from external influences, or as a sealant. Let's use lead in everyday life. In the form of shot and buckshot, it is used by hunters, and fishermen make weights out of it. Creative people living in the world of art can embody their ideas in it. Merchants need it in the form of weights.

Lead does not corrode in either sea or fresh water, but it is toxic, especially its water-soluble and volatile compounds, such as lead acetate and tetraethyl lead. Therefore, it is not used in the food industry. But the metal is suitable for pipes transmitting technical water. A huge mass of this metal, which is ideal in many respects, is consumed by the cable industry, where all kinds of wires are protected from corrosion with lead. And in alloys with tin, bismuth and cadmium, it is suitable for fuses and fitting contact parts to each other.

Lead sheets are produced in accordance with the requirements of State Standard 9559-89 by hot or cold rolling, depending on the purity of the alloy, they are marked accordingly - C0, C1, C, C3. The weight of a standard lead sheet, depending on the thickness, can vary from 2.84 to 56.85 kg. The surface of lead rolled sheet, its shear cut, manufacturing accuracy, trimming evenness must meet certain technical requirements. On each sheet with indelible paint, or on a paper label, or with a trademark, the name and trademark of the manufacturer, the brand of lead and the batch number are indicated. Sheets up to 0.8 mm thick are stored and transported in rolls on a wooden base wrapped in paraffin-impregnated paper.

During storage, the sheets must be protected from moisture and active chemicals. It is necessary to prevent their mechanical damage. If these simple conditions are observed, the properties of lead sheets will not change during storage for a long time.

Application area

Sheet lead is commonly used for roofing, especially flat roofs, and is intended to provide a waterproof seal to a building. Its lead sheets are quite durable due to their strength, providing extended protection against weather conditions such as rain, snow and hail. Sheet lead roofing is highly preferred due to its ability to create a smooth, seamless surface, which ensures that water will not seep through the roof surface. When properly installed, sheet lead roofing can last up to 80 years or more.

Retail lead sheet is also widely used for plumbing applications. It is an excellent choice for making pipes, valves and fittings. Sheet lead is easy to work with and can be easily shaped. In addition, sheet lead is corrosion resistant, making it an excellent choice for plumbing purposes as it can withstand harsh disinfectants and chemicals that are used to clean pipes.

Insulating applications are another common use for sheet lead. It can be used as a noise barrier to reduce the transmission of noise from one room to another or from one area to another. In addition, sheet lead is good radiation shielding and is used in X-ray rooms, nuclear laboratories and other places that require protection fromionizing radiation. Sheet lead is also used in fire doors, fire curtains, and other fire resistant materials because it has a high fire resistance.

One of the advantages of using sheet lead is its malleability, making it easy to work with even for people with limited experience. This metal can be easily cut, bent and shaped to suit the specific needs of the application. It also makes sheet lead a popular choice for DIY activities, allowing homeowners to do the repairs themselves, thus reducing costs and time. In addition, lead sheet's high strength ensures long-term results, making it a cost-effective choice for multiple applications.

Thus, sheet lead is a versatile metal with exceptional strength, corrosion resistance, and malleability. It is used for a wide range of applications, from roofing and plumbing to insulation and more, providing long lasting and reliable results. This metal is easy to work with and comes in a variety of thicknesses, making it a popular choice for professionals and DIYers alike. Due to its excellent properties, sheet lead is an excellent investment for any project.

Lead sheets have become an excellent roof covering material. Lead sheet is a reliable roofing material that is also used for fixing stove and fireplace pipes, as a protective covering for walls or stone.

Sheet lead has good sound insulation qualities and can muffle sound waves. So, doors made of lead absolutely do not let sound through. In addition, it prevents the spread of gamma rays, and if necessary, lead sheets can be used as protective screens from ionizing radiation and its other varieties.

Lead shielding can be seen in the laboratory, X-ray room, and other facilities where the effects of radiation need to be neutralized. Lead sheet is used as a material for the production of doors, screens, screens, as well as anti-radiation "clothes": aprons, collars, vests.

Low thermal conductivity as one of the qualities of rolled lead explains its demand in the metallurgical and engineering fields. Lead sheets and rolls can be used to create batteries and cables.

The most common product, the production of which cannot be imagined without a lead sheet, is a battery plate. Its production takes up to 30% of the total amount of lead mined in the world. Thus, mechanical engineering (automotive industry, aviation industry, etc.) cannot do without the use of rolled lead.

A bronze ribbon is a flat product made of an alloy of copper and tin. The tape can be made both from pure bronze and from its various modifications with the addition of other metals such as aluminum, nickel, zinc and others.

The bronze tape has high strength, corrosion resistance, and good heat resistance. It can be easily machined and welded, making it a popular choice for a variety of industrial applications.

The use of bronze tape is widespread in machine-building, electrical and other industries. It is used to make springs, hardware and tools, and to create decorative items.

To make a bronze ribbon, an alloy of copper and tin is heated to a certain temperature and then pulled through special molds until the desired width and thickness is obtained. The tape is then heat treated to eliminate internal stresses and improve its performance. On the site https://www.atissteel.ru/bronzovij-prokat/bronzovaja-lenta/ you can get more information about the bronze ribbon.

– Ingredients: copper, tin, zinc

Bronze tape is a material that is used in various industries. For example, bronze tapes can be used as electromagnetic shields, thermal barriers or heat conductors. Bronze ribbon is made from a metal called bronze. It is made up of copper, tin and zinc.

These metals are combined in certain proportions to create a material with certain properties. Bronze tape has high strength, good corrosion resistance and excellent electrical conductivity.

The use of bronze tape can be very diverse. For example, it can be used as a material for making metal pipes, which are used in various industries such as electronics, automobiles, medicine, and many other fields. Bronze ribbon can also be used as a material for making parts and tools.

- Production technology

Bronze ribbon is a type of metal ribbon made from an alloy of copper and tin. Other metals can also be used as components, for example,ink or nickel, to give additional properties.

The production process begins with the fact that copper and tin are mixed in the right proportions and heated to the melt temperature. The mixture is then poured into a mold where it cools and hardens into a bronze ingot. Next, the ingot passes through a rolling mill, where it is formed into a strip of the desired thickness and width.

Bronze ribbon has a number of useful properties that make it popular in various industries. In particular, bronze has a high corrosion resistance and good wear resistance, which allows it to be used for the manufacture of machine parts that are subjected to constant friction.

Also, the bronze ribbon is widely used in the jewelry and decorative industries due to its beautiful golden color. In addition, it is easy to process and has a low level of toxicity, making it safe to use in contact with food and other products that may enter the human internal environment.

If we consider the use of bronze tapes in industry, then, first of all, they are used as components of electronic systems. This sector of the economy makes high demands on finished products, which also affects the quality of raw materials: the percentage of impurities in the composition of bronze sheets should be minimal.

The second sector of application is mechanical engineering. In this direction, it is impossible to single out any specific type, since in fact 40% of today's industrial machines have bronze elements, the blanks for which are a bronze rolling strip.

But, despite this, one type of mechanical units can be distinguished, in which it is literally impossible to do without bronze elements made by rolling or stamping. These are hydraulic pumps that are used in the aviation industry. It should be noted that high requirements are imposed on aviation parts in terms of sealing in rotation units, reciprocating mechanisms, and plunger pairs. These requirements are met through the use of bronze seals made from bronze bands.

In plunger pumps, a large number of rubbing piston-like elements are used, which are subject to rapid wear. Despite the use of various types of anti-friction lubricants and cuffs, the tightness of pumps decreases with increasing operating time. To reduce the influence of this negative effect, bronze seals were used: washers, bushings and gaskets. Why bronze? The answer is simple. Bronze has a low coefficient of wear from friction, a low coefficient of thermal expansion and a relatively high hardness to withstand high cyclic loads.

No questions about this product, be the first and ask your question.