Dnieper sheet aluminum orange peel STUCCO (skin) corrugated 0.5, 0.8, 1, 1.5mm

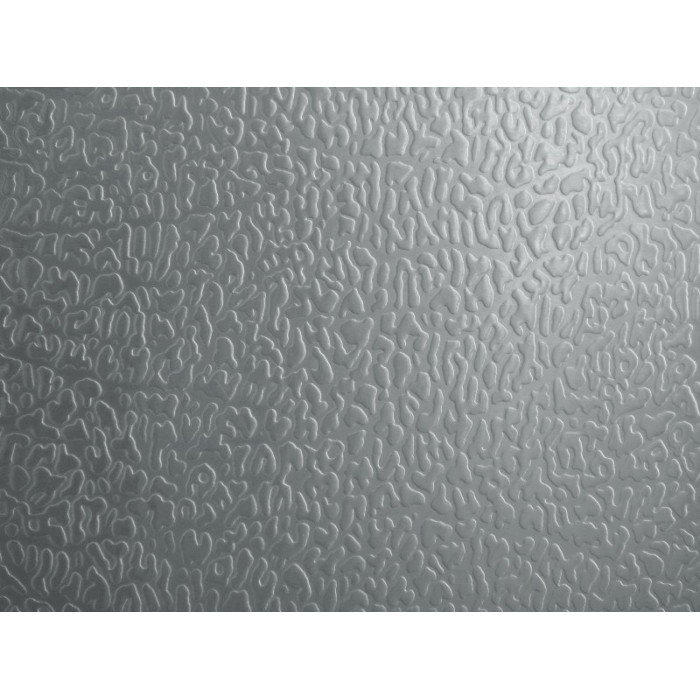

Embossed aluminum sheet, “embossed”, “orange peel” is a sheet with a small relief pattern, similar to an orange peel, obtained by extrusion.

Embossed aluminum sheet is used for interior and exterior decoration.

This is a decorative aluminum sheet that is widely used in the construction industry, interior decoration, including shop windows, exhibition stands, etc. Orange peel is widely used in the production of equipment for the food and chemical industries.

Aluminum sheet metal and various types of decorative orange peel pattern, mainly for classic orange peel pattern aluminum sheet metal and mutation pattern aluminum sheet metal. Refrigeration industry air conditioning refrigerators for orange peel pattern aluminum sheet application requirements, the largest in some packages.

Refrigeration equipment generally use orange color aluminum sheet, thickness 0.3 to 1.5mm, width 800-1200mm, generally can according to customer needs make you from need specifications.

Use orange peel decorative pattern in the aluminum alloy market, commonly used grades are 1060 or 3003, different alloy grades have different advantages, 3003 has the best anti-corrosion performance, the customer can call Haomei Aluminum, if necessary, we will recommend you according to your actual demand for suitable aluminum products for you.

The most commonly used corrugated aluminum sheet:

As a universal material for the installation of anti-slip flooring on stairs, in vehicle interiors, industrial refrigeration units.

For facing walls and partitions in interiors, for exterior decoration of buildings and structures, in factories and directly in the food industry.

For the implementation of design projects, the construction of theater and show scenery, in amusement parks for flooring (carousels, etc.)

A very important characteristic that determines the scope of the corrugated aluminum sheet is the high intrinsic safety of the alloys from which this type of rolled metal is made.

This type of rolled metal is usually used in construction as a protective, reflective or decorative element. It is an eco-friendly and durable material with an aesthetic appearance and relatively low weight. It is absolutely safe for humans and is used even in the food industry.

Decorative orange peel and quintet aluminum sheets are often used for column cladding in supermarkets, car interiors, and other places where surface protection from impact and abrasion is required without losing visual appeal.

At present, aluminum sheet is the most practical type of non-ferrous rolled products, which is used in mechanical engineering, aircraft building and shipbuilding and other industries. Its cost is low, because. raw materials are found in abundance in natural deposits, this is one of the cheapest metals. Such a sheet is very strong, light, flexible, durable and plastic. It lends itself perfectly to cold processing, and therefore products from it can be obtained in any configuration. It has a good thermostatic effect, is resistant to chemicals and is non-magnetic. It is resistant to corrosion, biologically inert, meets the strictest sanitary standards, which allows it to be used in any field of activity. This material has an aesthetic appearance, is easy to paint, retains its color for a long time, and does not require time-consuming maintenance.

Aluminum sheet is a rolled product, which is made from aluminum alloys. It is most in demand in mechanical engineering, aircraft building and shipbuilding. Aluminum sheet, in the production process goes through the following stages of processing:

- cold deformation (rolling/drawing);

- hot deformation.

Aluminum is a ductile material that can be easily cold-formed, resulting in parts of the required shape.

Aluminum sheet is made from aluminum alloys according to GOST 21631 standards. It should not have visible defects on the surface, for example, cracks, bubbles, corrosion spots, tears.

Also, burn marks are not allowed on aluminum sheets - the surface must be glossy or matte." https://stroirem.net

Corrugated can be distinguished by the number, type, location of notches

"Quintet" - five corrugations of each group, located parallel to another group.

"Duet" can be distinguished by two parallel grooves - notches.

"Orange peel" has a profile with dots and protrusions randomly located on the surface, like the peel of an orange.

aluminum sheet quintet close-up

The ornament is extruded when rolling sheets of special grades of aluminum, so it has a high degree ofyu strength. There are also other types of corrugated. "Diamond" (another name for "diamond") has the shape of a corrugation in the form of a crystal resembling a diamond. Perpendicularly arranged notches on the surface are called "Lentil". The full assortment of corrugated sheets: "quintet", "duet", "orange peel" is placed in the catalogue. To find out the price, leave a request, we will respond within an hour.

Applications, features and benefits of the material

The main properties of aluminum sheet with a corrugated surface are high slip resistance. The coating provides the necessary security, and the notches do not wear off over time, do not interfere with walking or the movement of mechanisms.

Corrugated aluminum sheets are chosen when the product is important:

A light weight.

Corrosion resistance.

decorative effect.

Non-slip surface.

Fire safety.

Ease of installation.

Trouble-free care.

Sheets are used for:

Production of steps of a ladder, a flooring of spans or scaffolds.

Overpass equipment, technological platforms.

Facing of floors in transport, special equipment.

Manufacturing of commercial equipment.

Facings of elevators, tuning of a car.

Deck equipment for boats.

The material withstands mechanical or shock impacts, does not corrode, does not collapse under the influence of aggressive chemicals. Thickness is from 0.8 to 5 mm, the most common size is 2 mm. Also, a corrugated aluminum sheet is often used in construction when erecting buildings and structures for various purposes. In the automotive industry, the product is used to arrange the floor. The anti-slip surface prevents passengers from falling while the vehicle is moving. An aluminum sheet, unlike a steel sheet, is lighter and cheaper, it is softer and more flexible. Aluminum sheets are used in the home to make trays for quail hawks. They are easy to clean with a wide spatula. Also, these sheets are used to make various parts for strengthening the roof and small roofs for chicken and cat houses and for birdhouses. Aluminum is used to stamp car bodies, doors, hoods and bumpers, and some engine parts are also made. Sheets with a corrugated coating are used in public transport. In buses, trams and trolleybuses, they are screwed to the floor to create a non-slip surface to ensure the safety of passengers. Chips and burrs on the edges of the sheets are not allowed in production. Such sheets are rejected. They should be smooth, of the same size and thickness and without holes. Aluminum is easy to machine. It is easy to drill, weld and cut. When working with this metal, observe safety precautions. Wear glasses to protect your eyes. Use special gloves to protect your hands. Buy aluminum sheets only from trusted suppliers who have a license to manufacture this product. This will save you from buying low-quality and defective goods. Billboards on highways and streets are made of aluminum sheets. Several sheets are welded together and they form a large advertising board. In some cases, corrugated sheets are used as a decorative element. They are used to cover support columns inside grocery supermarkets. Such polished sheets have a very unique aesthetic appearance. In shipbuilding, corrugated sheets can also be fixed to the floor in the corridors between cabins and decks to create a non-slip surface. This is especially useful when the ship is constantly rocking on the waves. Aluminum is used to make some parts for airplanes and helicopters, it is used in the space industry to make some rocket parts. This metal makes wonderful canisters for storing and transporting gasoline. If you wash and polish them, they will have a wonderful appearance. Nowadays, the scope of aluminum application is very wide and is in great demand in many areas of industry.

No questions about this product, be the first and ask your question.