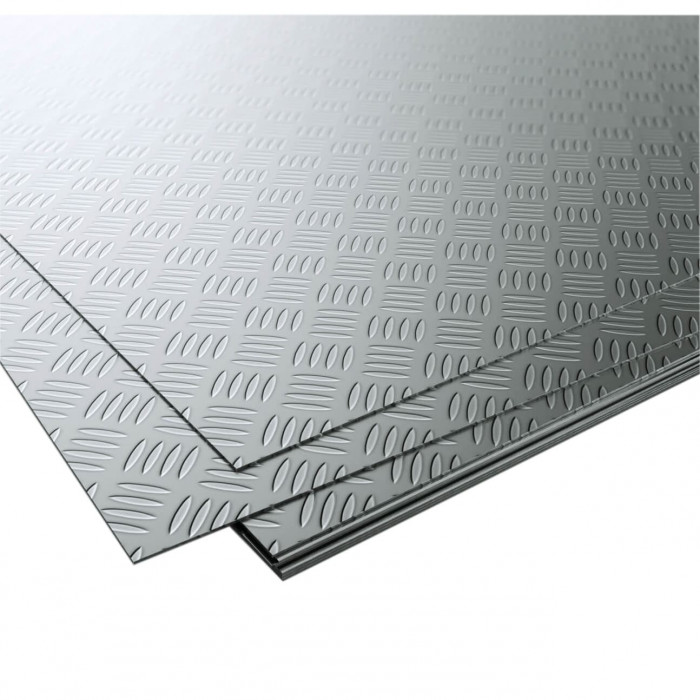

Ivano-Frankivsk aluminum sheet AD31, AD0, D16T, AMG5, corrugated sheet, 1x2m, 1.25x2.5m, 1.5x3m

The use of rolled sheets in various fields of human activity is due to ease of use, a fairly low price and a wide variety of their types and types. Unlike corrugated steel sheets, aluminum sheets have better aesthetic and physical and chemical properties.

The material itself is an aluminum alloy with a different content of copper, manganese and magnesium, called duralumin. Physico-chemical characteristics depend on the number of components.

Scopes of corrugated sheet

Due to their properties, they are used in many industries and construction. They are most widely used in:

Scope of application

Construction, as a finishing material with good corrosion resistance, is much better than steel;

Design, in the form of a coating for interior decoration in the style of "hi-tech";

Ship, aircraft, automotive industry as the main material of the hull, and as auxiliary structures;

Oil and chemical industries as platforms and ladders on tanks and equipment.

They are also used when it is necessary to perform light, strong and aesthetic structures. Often such designs can be found in the design of promotional products, storage racks, furniture, etc.

Its use in various service platforms and stairs is due to its good corrosion and wear resistance. Good anti-slip performance ensures safe movement on such sites, regardless of weather conditions.

Types of corrugated sheets

They differ in several characteristics and must comply with GOSTs:

Alloy brand, the main ones are: AMg2, VD1, AMts;

Mode of production;

post-processing;

drawing type;

Overall dimensions and thickness.

Mechanical and corrosion properties depend on the brand. For example, AMts has increased corrosion resistance, but worse strength. VD1 has good strength and ductility characteristics. AMg2 is the most versatile alloy with good mechanical and corrosion resistance properties.

The type of pattern is due to the corrugation of the surface. The word corrugation comes from the word corrugation, which means a groove, notch or groove of small height on the surface. According to the type of pattern and shape, they are divided into several types:

Types of corrugated sheets

"Lentil" is a pattern of the same type (lentil) with one corrugation, which is applied over the entire surface at regular intervals. It is located horizontally in one row, then with one, then with another slope.

"Duet" - two riffles, also going in one row, but with a staggered arrangement. The slope of the flute changes in each row.

"Quintet" - consists of five parallel flutes arranged in a checkerboard pattern. The slope of the flute in the rows changes.

"Quintet" is the most common type of corrugation, as it has the best anti-slip effect. But it is also quite expensive, since the cost of its manufacture is greater than for less complex drawings.

There are several other types of drawings. Rifles on them can be mutually perpendicular, with different pitches and positions. The choice of pattern is not only a practical, but also an aesthetic choice. Using various combinations, you can achieve interesting design solutions.

Methods and features of the production of aluminum corrugated sheet

Rolled products, which are produced in accordance with GOST, are produced with a length of 2.0-6.0 m, a width of 1.0-1.5 m, and a thickness of 1.5-4.0 mm. The shape of the material is rectangular: bulges of different geometry are created on the surface. Depending on the sequence of arrangement and type of pattern, there are three versions of corrugated aluminum sheet.

"Diamond". A simple pattern has one corrugation, which is evenly applied to the surface.

"Duet". Two corrugations are created on the product, located perpendicular to each other in a checkerboard pattern.

"Quintet". The most intense drawing. The composition, which consists of 5 flutes, is located perpendicular to each other.

Depending on the original alloy, corrugated aluminum sheets are created in different ways. According to the general scheme, the production of rolled products involves four stages:

ingots weighing up to 3 tons are poured from molten aluminum raw materials;

billets made from ingots are hot-rolled;

if provided by the technology, cold rolling follows;

Finally, heat treatment and finishing are carried out.

Not all aluminum alloys are subjected to heat treatment. For example, workpieces containing manganese go through another production stage - work hardening. After completion of this process, the metal becomes hard, strong and relatively less ductile.

What do the letters and numbers say?

To the combination of letters denoting the grade of the alloy, letters are added that inform about the state of delivery, in this case, corrugated sheets:

M - annealed (soft; after annealing, the metal becomes more ductile and malleable);

H - cold-workeds;

H2 - semi-hardened;

T - hardened and naturally aged;

T1 - hardened and artificially aged;

R - made of refined aluminum.

So, sheets of alloys 1105 and VD1 can be supplied:

1105AT, VD1AT - hardened and artificially aged;

1105AM, VD1AM - annealed;

1105AN, VD1AN - hard-worked.

VD1AN2 - semi-hardened;

VD1NR - made of refined alloy, hard-worked.

The presence of the letter "A" indicates that this is a corrugated aluminum sheet with a normal plating. (Clading is the application of a thin layer of metal to the surface of products to increase corrosion resistance). Unclad sheets are not specially marked.

Corrugated sheets are easily connected by welding, therefore they are in demand in various fields of activity. The product is widely used in industry and agriculture. Decorative corrugation allows the use of aluminum sheets during finishing work. Sometimes the product finds application in interior design and structures.

Applications:

Shipbuilding;

Automotive;

aircraft industry;

Furniture manufacturing;

Manufacture of stairs, racks and other structures.

Also, a corrugated aluminum sheet is often used in construction in the construction of structures and structures for various purposes. In the automotive industry, the product is used for arranging the floor. The anti-slip surface prevents passengers from falling off while driving. Aluminum sheet, unlike steel, is lighter and cheaper, it is softer and more flexible. Aluminum sheets are used in households to make trays for quail hawks. They are easy to clean with a wide spatula. Also, these sheets are used to make various parts for strengthening the roof and small roofs for chicken and cat houses and for birdhouses. Aluminum is used to stamp bodies, doors, hoods and bumpers for cars, and also to make some engine parts. Sheets with a corrugated coating are used in public transport. In buses, trams and trolleybuses, they are screwed to the floor to create a non-slip surface to ensure the safety of passengers. Chips and burrs on the edges of the sheets are not allowed in production. Such sheets are rejected. They must be smooth, of the same size and thickness and without holes. Aluminum is easy to machine. It is easy to drill, weld and cut. Observe safety precautions when working with this metal. Wear glasses to protect your eyes. Use special gloves to protect your hands. Buy aluminum sheets only from trusted suppliers who have a license to manufacture this product. This will save you from buying low-quality and defective goods. Billboards on highways and streets are made of aluminum sheets. Several sheets are welded together and they form a large advertising board. In some cases, corrugated sheets are used as a decorative element. They are used to cover support columns inside grocery supermarkets. Such polished sheets have a very unique aesthetic appearance. In shipbuilding, corrugated sheets can also be fixed to the floor in the corridors between cabins and decks to create a non-slip surface. This is especially useful when the ship is constantly rocking on the waves. Some parts for airplanes and helicopters are made of aluminum, it is used in the space industry to make some rocket parts. This metal makes wonderful canisters for storing and transporting gasoline. If you wash and polish them, they will have a wonderful appearance. Nowadays, the scope of application of aluminum is very extensive and is in high demand in many areas of industry.

No questions about this product, be the first and ask your question.