Ivano-Frankivsk hexagon steel 40X, st45, st35, st20, 30HGSA, 09G2S, calibration square steel U8A, 65G, 40HN2MA, keyed steel, strip, sheet, circle

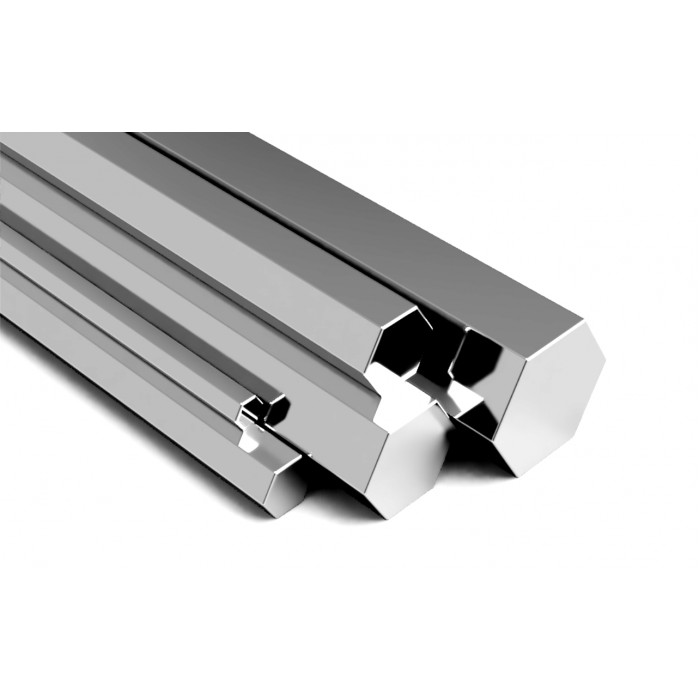

Steel hexagon - a type of long products, the cross section of which is a regular hexagon. Produced in accordance with GOSTs 2879-88 and 8560-78. It is used for the manufacture of car parts, machine tools, devices, fasteners (nuts, bolts, screws) on metalworking machines and automatic machines, for the creation of metal supports, fences, furniture and decor elements. Depending on the intended application, carbon and alloy steel grades are used in the production of a steel hexagon. Rolled products from stainless grades, capable of working in contact with aggressive media, are in demand in the food industry.

Types of hexagon depending on the production method

The properties of hot-rolled products are regulated by GOST 2879-88. According to the standard, the assortment of hot-rolled steel hexagon includes products with an inscribed circle diameter of 8-100 mm, with rolling accuracy "B" (increased) or "C" (normal). At the request of the customer, manufacturers can produce products of large sizes.

Hexagonal calibrated steel is produced in accordance with GOST 8560-78 from hot-rolled billets by cold rolling or drawing. The main difference between calibrated products and hot-rolled products is improved surface quality and dimensional accuracy. Calibrated rolled products from free-cutting steels are used in the production of tools for high-speed machining. A steel hexagon is a steel product with a hexagonal cross-section. Various car parts and repair tools are machined from it: screwdrivers, wrenches, anchors, bolts, screws, chisels, gouges and taps. When buying it, pay attention to the manufacturer, they must have a license to sell such goods. This will allow you to avoid buying a low-quality product. It is resistant to rust, temperature changes and is very durable. Hexagons are easy to process - they are cut, drilled and welded. When working with them, you should follow safety precautions - protect your hands with special gloves, and your eyes with protective glasses to avoid small particles getting into them. They are made from two to six meters long.

Classification of hexagonal steel by size

The size of products is characterized by the diameter of the inscribed circle (the distance between parallel faces). In practice, this size coincides with the number of the key suitable for unscrewing / tightening fasteners.

What steels are hexagons made of?

For the production of hexagonal rolled products, unalloyed (structural) and alloyed alloys are used. In the first case, the steel contains a small proportion of carbon (0.1-1.5%), manganese (up to 1.65%), copper and silicon (0.6% each). This group includes steel grades St20, widely used for the manufacture of hexagons (can be replaced by analogues with similar characteristics St15 or St25), St30, St40 and St45. The total volume of carbon steels (structural, cemented) used in production is more than 85% due to low price, ease of processing, versatility.

The alloyed composition is obtained by adding additional alloying components to the carbon mass, which give the workpiece additional properties: increased strength, flexibility, tensile or bending resistance, and corrosion resistance. Such additives can be tungsten, nickel, molybdenum, manganese, chromium, titanium, copper, boron, etc.

Alloyed materials are used for the production of stainless hexagonal steel. GOST 4543-71 divides alloyed alloys into several groups based on the predominance of the main alloying additives:

manganese;

chromic;

chrome-silicon;

chrome-vanadium and more than 10 groups of steel grades.

The main brands are 45X14H14V2M (EI 69), 08X18H10, 316L, 20X13, 13X11H2V2MF (EI-961-Sh), 08X18H10T, 14X17H2 (EI 268), 12X18H10T, 40X13.

Production of steel hexagons

Manufacturers of rolled steel use three technologies to produce reinforcement with six faces: cold and hot rolling, pressing. The choice of method depends on the request for a specific type of product, equipment, availability of raw materials and other factors.

cold rolling

A method of working steel by pressure, in which billets are passed through a rolling mill with two rollers. Under pressure, the metal is deformed, acquiring a hexagonal shape. The difference from hot rolling is that pre-heating of the workpieces is not required. The rollers are supplied with a lubricating fluid (mineral, vegetable, animal origin), which reduces the coefficient of friction and removes heat from the contacting surfaces. Cold rolling produces calibrated hexagons, the properties of which are formalized in GOST 8560-78, as well as their analogues from alloyed steels according to GOST 4543. Advantages of the processing method:

high quality of product surfaces;

production of thin rolled metal products;

ease of welding.

hot rolling

The technology for producing bars with six faces in a hot way involves heating the workpieces above 60-70% of the recrystallization temperature in accordance with GOST 2879-99. The deformation of hot-rolled rolled metal occurs in the same way as with cold crimping. Pros: a wide range of rod thicknesses (up to 200 mm), a relatively low price due to the low cost of alloy grades used in production.

hot pressing

During pressing, the metal is passed through a matrix with a hexagonal hole, the resulting bars fall into a container for finished products. Equipment - factory high-pressure presses. Raw materials undergo preliminary preparation (cutting, heating, descaling. Pressed rodand are accurate in size and shape.

Classification of hexagons

Rolled metal in the form of rods with six faces is classified according to several parameters and characteristics: length, chemical composition, processing accuracy. the curvature of the rods, the condition of the material and the type of surface treatment.

Length

Manufacturers ship products with different lengths, this characteristic can be:

measured (bars have a standard length - 2, 6 or 12 m);

unmeasured (rolled metal is made according to arbitrary sizes, which the customer needs - from 2 to 12 m);

multiple measured - the rods are produced in length, a multiple of, for example, 2 m: 4 m, 8 m, 10 m.

Machining accuracy

Depending on the properties of the material and the characteristics of the factory equipment, rolling can be high-precision (category B) or conventional (category C). In high-precision processing, the bars are ground, eliminating coarse roughness, removing scale and irregularities.

Chemical composition

The indicator depends on the type of steel used to produce products:

for the manufacture of blanks of ordinary quality, carbon steels are used, high quality products are achieved by using high-carbon, alloyed steels.

Material condition

Depending on the production technology, the properties of steel change:

heat treatment;

hardening.

Heat treatment is carried out on carbon, alloyed alloys belonging to the categories of instrumental, special or structural. Changing the internal structure of the metal leads to an increase in strength, resistance to corrosion, and an increase in ductility.

Surface treatment method

Giving a hexagonal shape and given dimensions to the bars is achieved by forging, hot or cold rolling (calibration). The best properties (smoothness, visual beauty, minimum roughness, absence of scale and other defects) are achieved by forging or pressing.

Bar curvature

The degree of curvature of a bar with six faces depends on the curvature class:

Class I - products with a curvature of up to 0.5% with a length of up to 0.4 m (0.4% with a length of more than 0.4 m);

Class II - curvature index 0.5% for the rest of the assortment.

Areas of application for hexagons

Hexagonal rolled metal products are used as blanks in the production of fasteners and hardware products. Nuts, bolts, screws, studs, anchors, keys are made from a steel tool bar of grades 40X, St45. Fittings with six edges made of extra-strong alloy steels are suitable for the production of power tool accessories: extension cords, bits. Bars made of ductile carbonaceous metals serve as raw materials for manufacturers producing chisels, screwdrivers, taps, axes, and chisels.

High strength, wear resistance, corrosion resistance, durability make rolled metal suitable for use in construction, construction of metal structures, bridges, viaducts, the manufacture of railings for stairs, open areas.

Delivery type

Hexagonal hot-rolled steel is supplied in bars of fixed length from 2 to 6 meters; in agreement with the customer, the manufacturer can supply rolled products in the form of coils, which is agreed with a separate specification.

Also, in agreement with the customer, hexagonal rolled products are supplied in random lengths ranging from 3 to 13 meters, while it is assumed that 10% of the bars from the weight of the supplied batch may be less than 3 m long.

No questions about this product, be the first and ask your question.