Ivano-Frankivsk ropes, cables, chains galvanized, stainless GOST, DIN, wire cutting and delivery

Galvanized steel rope is a product twisted from steel wire. In its manufacture, thin rods (threads) of various thicknesses and qualities are used. All of them twist in a spiral in one strand. Any rope consists of several twisted strands of the same type and a metal or organic core. The core is located in the center of the cable, fills its void and prevents adjacent strands of wire from falling through. Impregnated with anti-corrosion grease, it protects the inner layer from corrosion when the cable is bent. The wire used can be galvanized or uncoated, have a round or shaped section. Its tensile strength is in the range of 900 to 3500 N/mm2. The number of strands in the rope, which are located around the core, determine its structure. galvanized steel rope Steel ropes differ from each other in cross-sectional shape, physical and mechanical characteristics of the wires and have a large number of designs. The material grade, core type, lay direction, number of wires per strand determine the flexibility and rigidity of the rope. The more wires used, the more flexible the rope. GOST steel rope Depending on the operating conditions, steel ropes are divided into traction, reinforcing, lifting, cargo, towing, mine, bearing, etc. These products are widely used in many industries and utilities. Steel ropes are a load-bearing element of transport, road construction, lifting structures and machines. The quality of these devices ensures the safe use of all lifting mechanisms. By design, steel rope (GOST 3241-80 or DIN 3051) is divided into the following types: Single lay. Such a cable consists of one strand. He has wires of the same diameter retinue in one layer (or several layers) around one wire. Double lay. This rope consists of several strands, which are one or two layers, and are located around the core. Triple lay. It consists of three strands that are twisted together and do not have a core. The twist of the strands can be cross, one-sided or combined, left or right direction, untwisted or non-untwisted twisting method. Inside, the strands of wire have a point, line, or point-to-line touch. Steel ropes are characterized by the following formula: N * M + L, where N is the number of strands, M is the number of wires in one strand, L is the number of cores in the rope. For example, the entry 6 * 36 + 1 means that the rope consists of six strands, each of which contains 36 wires, and one core. steel ropes Steel ropes should be stored tightly wound on spools (bobbins) or rolled into small coils. From the impact of an aggressive environment, the bay with a cable should be protected by a canvas cover located on a wooden pallet (in sunny weather, the casing is removed). Excessive bends are harmful to the cable. Therefore, the container for it is selected carefully. With proper storage of the rope, the service life of the product is not limited.

According to the design feature, the steel rope (GOST 3241-80 or DIN 3051) is distinguished by the following types:

Single lay. Such a cable consists of one strand. He has wires of the same diameter retinue in one layer (or several layers) around one wire.

Double lay. This rope consists of several strands, which are one or two layers, and are located around the core.

Triple lay. It consists of three strands that are twisted together and do not have a core.

The twist of the strands can be cross, one-sided or combined, left or right direction, untwisted or non-untwisted twisting method. Inside, the strands of wire have a point, line, or point-to-line touch.

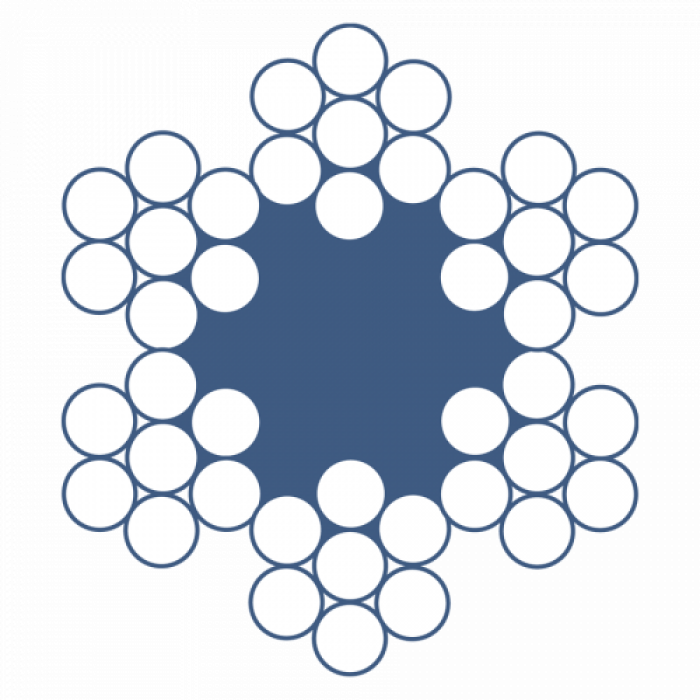

Steel ropes are characterized by the following formula: N * M + L, where N is the number of strands, M is the number of wires in one strand, L is the number of cores in the rope. For example, the entry 6 * 36 + 1 means that the rope consists of six strands, each of which contains 36 wires, and one core.

Steel cables should be stored tightly wound on spools (bobbins) or rolled into small coils. From the impact of an aggressive environment, the bay with a cable should be protected by a canvas cover located on a wooden pallet (in sunny weather, the casing is removed). Excessive bends are harmful to the cable. Therefore, the container for it is selected carefully. With proper storage of the rope, the service life of the product is not limited.

Steel ropes and chains belong to the category "Hardware" - metal products. The steel rope itself performs the functions of the main load-bearing element in all lifting mechanisms. Therefore, the scope of its application is extensive and extends to almost all spheres of human activity. If we talk about its technical characteristics, then it is necessary oncedeal with the classification of ropes.

Classification

There are different parameters of steel ropes that divide them into classes and groups. And all of them are very different from each other, which is fixed by GOSTs. Therefore, the technical characteristics of steel wire ropes should be considered in terms of their belonging to one or another class.

To begin with, the design includes a core and wires from which strands are knitted. The core in the design acts as a base, while it gives the product flexibility and retains lubricant. It can be a monolithic wire or a strand of two or three strands. It can be both a metallic element and organic materials: hemp, cotton yarn, manila, and so on.

Strands of wires that wrap around the core can be twisted from wires of the same diameter or from different ones. The first position is called the normal section, the second is the combined one.

Types of steel wire ropes

Purely structural steel rope is divided into three groups.

Single lay.

Double.

Triple.

The first option is a cable consisting of 1-3 wires that are twisted into a conical spiral. Most often they are made from wires of round cross section, less often from shaped products. Typically, such ropes are used as lays with the same strand used for the manufacture of ropes with a more complex configuration of elements. They are called strands.

The second position consists of six or more strands. They are divided into single or multilayer. The latter have good technical characteristics, which include increased strength and flexibility with a large bearing surface. Such ropes have a large non-torque moment. Single layer double lays are usually used for laying into more complex structures. They are called strands.

The third position is, in fact, several strands twisted into one wire rope.

There is a division according to the type of wire contact.

Point touch. The lowest quality, because such steel ropes wear out quickly, due to the fact that the wires inside the twists intersect, and do not lie along the twisting axis.

Line touch. Such ropes are twisted in one go, and their wires do not intersect, but lie along the twisting axis.

Combined touch of strands.

Regarding lay direction, steel ropes are divided into left lay and right lay. There is also a division of them into untwisted and non-untwisted. The latter type has excellent characteristics that prevent the product from unwinding into individual elements. This is achieved by straightening, after which all rope elements retain their predetermined position under loads. Accordingly, there is a division into straightened and not straightened.

According to mechanical characteristics, steel ropes are divided into high-strength (VK) and ordinary (B). Currently, manufacturers offer products from ordinary steel and galvanized. Of course, the second position is higher in many respects, especially for the corrosion resistance of the product.

And the last classification of steel ropes is by purpose. In principle, he is considered one of the main ones. These are cargo-personnel ropes (GL), which are installed on elevators, and cargo (G) for all other mechanisms.

All positions of the classification are necessarily reflected in the marking. For example, 10.5-GL-VK-OZH-MK-L-N-R-T-1770 GOST 7668-80. What do these letters and numbers mean?

10.5 is the diameter in millimeters.

GL - cargo people.

VK - high quality.

OZh - galvanized.

MK - low-rotation rope.

L - lay left.

H - cable is not untwisted.

P and T - increased manufacturing accuracy.

1770 - marking group with the unit of measure N / mm² or 170 kgf / mm². In fact, this is the strength characteristic.

Manufactured in accordance with GOST 7668-80.

There is a fairly large list of GOSTs, in which each brand has its own technical characteristics. The most common are steel rope GOST 2688-80 and GOST 7668-80.

Quality control

Steel ropes used in production must be constantly monitored for quality. In this case, the defects found must be compared with such indicators as the rejection rates of steel ropes. To make it clear what we are talking about, look at the photo below, which shows various product defects.

Let's go through the points.

a) it is a cable kink;

b) the rope was crushed by something;

c) the core collapsed, so the configuration of the section changed;

d) wire was squeezed out of the strand;

e) wear of outer wires;

e) wire breakage.

If such defects were found, then the rope is rejected. If the defective sections are not very large, then the cable can be cut, removing the defects. In this case, of course, its length will decrease. But everything can be fixed if the two parts are spliced by twisting. The process is not easy, one might even say complex and time-consuming, for which various devices are often used.

Ropes brand GL(for lifting people) are rejected if the breakage of wires on one lay is 25% of their total mass. In cargo models (D), this figure can be twice as much. The same applies to the reduction of wire diameters due to corrosion. If the GL is 40% corroded, then it is immediately rejected. That is, the rejection standards for GL are much stricter. Other models are rejected depending on their operating conditions.

Loop on steel cable

Situations where a loop at the end of a steel rope helped out in emergency cases are very common. For example, you need to lower the load to some depth, or you need to tow a faulty vehicle. Therefore, the loop is a necessary element. More recently, it was simply braided with strands of the steel rope itself. True, the weaving process has always been difficult, requiring certain skills and knowledge.

Today, loops can be made quickly and easily using wire rope clamps and thimbles. There are several purely design features of the clamps, so they differ from each other in appearance and clamping mechanisms. But all of them are designed specifically for connecting two guides with a segment (sections) of ropes. It doesn't matter if these guide sections are part of one cable or two separate ones. It is important to correctly connect the two parts, correctly install the clamps and thimbles and firmly press the two parts of the clamps with bolted connections.

The thimble in this case will perform the functions of the rim of the loop installed from the inside. Therefore, most often the shape of the thimble is teardrop-shaped. Although manufacturers offer round thimbles, rectangular and triangular.

Attention! When installing the thimble in the loop, it is necessary that the rope fits snugly against it. The fixture itself inside the loop should not hang out.

Requirements

The main requirement is the conditions under which the strands and strands of the rope do not unwind. To achieve this, it is necessary to install the unwinding drum so that its axis is located in a horizontal plane.

In this case, the coiled end of the cable must always be located either in the lower or in the upper position.

If a cable product is unwound from one drum and immediately wound onto another, then the distance between them should not be less than 300 diameters of the cable itself.

In addition, the rope in the process of winding it on the drum must be wound around it without kinks.

But unwinding should be done only in a tense state.

Do not wind the rope on a non-rotating drum. To do this without kinks simply will not work.

It would seem that it is just a rope made of steel wires, but there are so many requirements for it. Therefore, those who work with metal cables need to know not only the rules and techniques for its use, but also the methods and parameters of its quality control.

No questions about this product, be the first and ask your question.