Kamianets-Podilskyi titanium sheet, circle, wire, pipe VT 1-0 , VT 6 , OT 4-0 , VT 14 from 6 mm to 350 mm, delivery

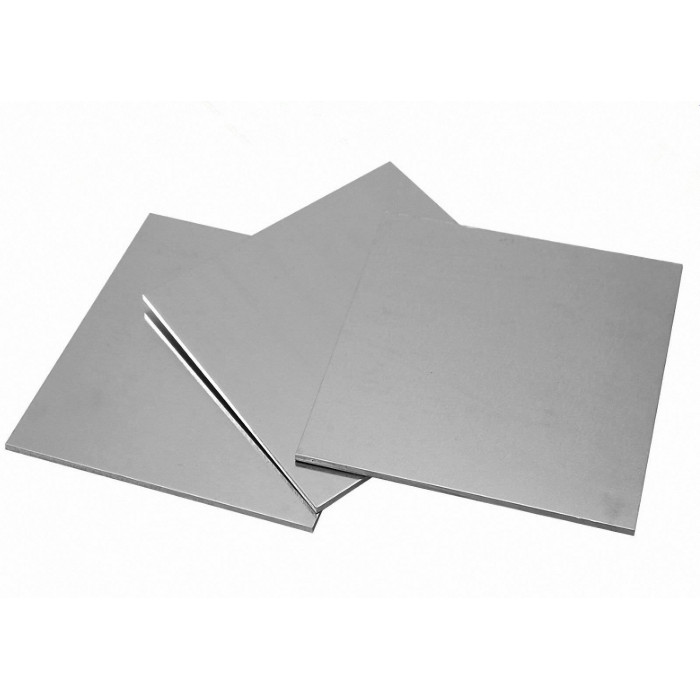

Titanium sheet is a titanium rolled product in the form of a rectangular layer with a thickness of 0.3 to 30 mm. Titanium sheet is made from various grades of titanium and its alloys.

Properties and characteristics of titanium sheets

The properties of rolled titanium are largely determined by the chemical composition of the metal, the method of processing and production, and the state of the material. The chemical composition of the metal is determined by OST 1 90013-81 or GOST 19807-74. The GOST 22178-76 standard regulates the manufacture of titanium sheets from alloys OT4, VT20 and titanium grade VT1-0.

Sheet titanium is characterized by high resistance to corrosion processes, lightness, strength. Rolled metal is easily welded, satisfactorily amenable to various types of mechanical processing, and is plastic. In addition, titanium sheets do not conduct heat well and are not magnetic. The popularity of titanium rolled products is due not only to its high resistance to corrosion damage, but also to the ability to retain useful properties, both at high and low temperatures. Sheet titanium is resistant to vibration, characterized by high resistance to fatigue loads.

Sheet titanium is classified according to the quality of the surface finish (high finish P, normal and high B), according to the method of sheet production (annealed rolled products with further smoothing and straightening, as well as annealed and melted titanium sheet), according to the deviation in flatness (normal flatness, improved U ).

According to the terms of GOST 22178-76, the maximum deviation along the length of the titanium sheet should not exceed the following indicators:

- with a sheet length of up to 2 m - plus 20 mm;

- with a titanium sheet length of more than 2 m - plus 25 mm.

The largest deviation in width:

- no more than 10 mm with a width of up to 1.5 m;

- no more than 15 mm with a titanium sheet width of more than 1.5 m.

The cut titanium sheet, according to GOST 22178-76, must be even, at a right angle, without coarse burrs on the ends. Tempering colors may be visible on the surface of the metal product, this is not considered a marriage, but tears, cracks, delaminations, various kinds of inclusions (metallic and non-metallic), captivity, traces of scale should not be present. The surface is etched.

Each sheet is subject to marking (angle, distance no more than 100 mm from the edge): grade of alloy or titanium, size, batch number, designation of technical control (in the form of a stamp).

Titanium sheet production

The production of high-quality titanium sheets is a rather expensive, lengthy and labor-intensive process. Metal products are made in two ways: cold or hot rolling. At the same time, cold-rolled titanium sheets are of higher quality than hot-rolled products. The technological process begins with forging or stamping titanium slabs from round ingots - thick blanks in the form of plates. The slabs are then hot rolled into strips. The surface layer of the semi-finished product has a fragile structure, saturated with nitrogen, oxygen, hydrogen, because actively interacts with surrounding gases. This layer is removed mechanically (cleaning, abrasives) and chemically (etching with molten alkalis or acids). Hot (warm - 650 - 750 ºС) rolling is carried out on semi-continuous and reversible tape mills. The technological process of cold rolling of titanium sheets provides for intermediate annealing at temperatures from 500 to 900 ºС in electric or vacuum furnaces (to prevent saturation of the surface layer of the titanium sheet with hydrogen). After the final etching, the protective properties of the metal are renewed.

Application of titanium sheet

Titanium is one of the most important and sought-after structural materials in our time.

Sheet titanium is widely used in shipbuilding, space, rocket, aviation technology for the manufacture of aircraft and aircraft. Sheets serve as plating for hulls, shafts, propellers, drives, wings and many other light and durable parts are made from them. Titanium sheet is used where reliability, durability and lightness are required; this type of rolled titanium is used to produce critical parts of equipment and structures, for example, skin and other elements of nuclear submarines.

Sheet titanium serves as a raw material for the production of heat exchangers. In the food, pharmaceutical and chemical industries, bodies of instruments and equipment, parts are made from titanium sheets. Thanks to the use of this metal, efficient, mass production of urea, potassium, soda, chlorine, various household chemicals, etc. has been established. Cases of high-quality household appliances are often made of titanium.

Part of sheet titanium is consumed by the metallurgical industry, for example, for the manufacture of welded titanium pipes, foil, etc.

Titanium sheet products are also consumed by industries such as gas production and petrochemicals. The use of titanium ensures long-term operation of equipment, apparatus, structures made ofit in highly aggressive environments. In construction, titanium sheets are used in facing works.

Material Features

Prolonged exposure to elevated ambient temperature and the state of the atmosphere are the reasons for the formation of a strong oxide-nitride film that performs the function of protection. Due to biological inertness - the main characteristic of titanium sheets, this material can be used in medical centers and food industry organizations. There is no such metal that could replace titanium with its quality and performance indicators, its price, however, is too high, but you have to pay for high quality.

Below are the main parameters of titanium sheets:

Their standard thickness is 0.3÷10 mm;

Their standard width is 400÷1200 mm;

Their standard length is 1250÷5000 mm.

In the manufacture of this material, the grades of the following alloys are used: BT1-00, BT1-0, OT4, BT6, BT20. The production technology makes it possible to obtain both hot-rolled and cold-drawn blanks. This sheet material can be straightened, annealed and ironed, high/high finish, normal/improved flatness.

As already mentioned, the cost of this material is very high. Why? Firstly, because of the long and laborious process of producing pure titanium material. Secondly, because of the payback of this metal, which does not lose its positive properties during a long service life. As a result, titanium does not need to be replaced in the production of a product whose strength / reliability will be preserved for many centuries.

By their appearance, titanium sheets can be:

straightened, annealed and ironed;

high and high finishes;

improved and normal flatness.

The high cost of titanium sheet is explained by the complexity and duration of the process of obtaining pure titanium. The payback of this high-quality metal is obvious - it has a long service life and does not lose its characteristics. It follows from this that it will not need to be replaced, and with all this, the strength and reliability of the product will be preserved.

Titanium sheet is used in shipbuilding, rocket building, aircraft building. Hulls, cladding and other elements are made from it, which must be of high quality and accuracy. Do not do without the use of titanium sheet chemical and food industries. A significant place is allocated to him in construction and medicine. Quite often, titanium sheet is used in the petrochemical and oil and gas industries.

With prolonged exposure to high temperatures and the atmospheric environment, a strong protective oxide-nitride film is formed on the surface of the titanium sheet, which performs a protective function. This rolled metal is also characterized by biological inertness, which makes it possible to use it in medicine and the food industry. The titanium sheet has no analogues that would have the same quality performance and retain them for many years. Titanium sheets are produced with thickness from zero point three to thirty millimeters. They are widely used in aviation due to their strength and lightness for the manufacture of aircraft skins. They are used in the automotive and railway industries. They are very resistant to temperature changes, aggressive chemical environments and fuels and lubricants. The sheets are easy to machine, they are cut into pieces of the required size. When working with this product, you should follow safety precautions. Protect your hands with special gloves and your eyes with safety glasses. Buy sheets only from trusted manufacturers who have a license to sell such goods in order to avoid buying counterfeits. Holes and cracks in them are not allowed in production. Sheets are packed and pulled together in several pieces for storage and further transportation. Titanium has high strength and durability, it will serve you for many years. It is used in various industries: automotive, agriculture, railway and shipbuilding.

No questions about this product, be the first and ask your question.