Khmelnitsky technical plate TMKShch, AMS, MBS, wide range, GOST

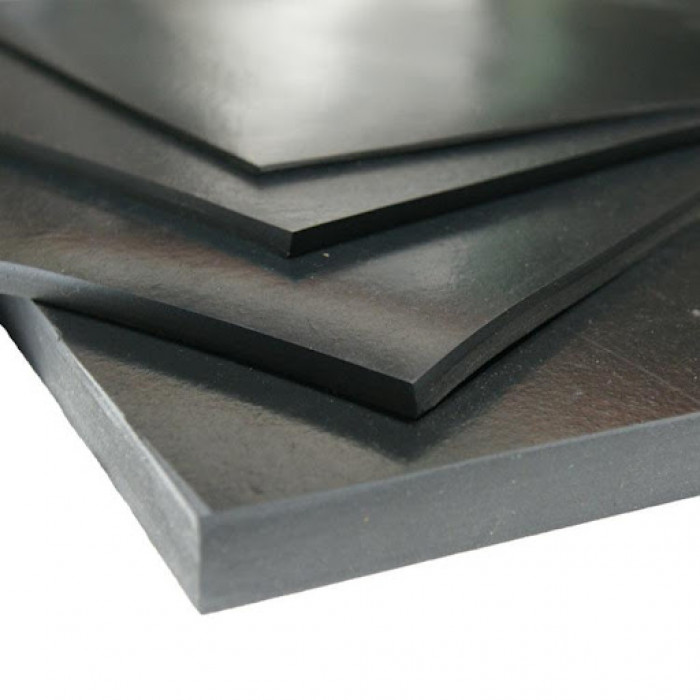

Technical platesTechnical plates are intended for the manufacture of rubber products used to seal fixed joints, prevent friction between metal surfaces, to absorb single shock loads, as well as gaskets, decking and other non-sealing products.

Plates, depending on the purpose, design and manufacturing method, are produced in the following grades:

TMKShch - heat and frost acid and alkali resistant plate TKMShch

Working environment of technical plate TMKShch: air of rooms, capacities, vessels; nitrogen; inert gases at a pressure of 0.05 to 0.4 MPa or fresh, sea, industrial, waste water without organic solvents and lubricants; a solution of salts with a concentration up to the saturation limit; acids, alkalis with a concentration of up to 20% at a pressure of 0.05 to 10.0 MPa.

TKMShch plate is operable at temperatures from -45oC to +80oC

We produce TKMShch plates in a wide range.

MBS - oil and petrol resistant plate MBS

Working environment of technical plate MBS: air of rooms, capacities, vessels; nitrogen, inert gases at a pressure of 0.05 to 0.4 MPa, or oils and petroleum-based fuels, gasoline at a pressure of 0.05 to 10.0 MPa.

MBS plate is operable at temperatures from -40oC to +80oC

We produce high quality MBS plates.

AMS - atmospheric oil-resistant (limited ozone-resistant) technical plate

The working environment of this type of technical plate: atmospheric air, rooms, containers, vessels; nitrogen; inert gases at a pressure of 0.05 to 0.4 MPa or petroleum-based oils at a pressure of 0.05 to 10.0 MPa.

Operable at temperatures from -40oC to +80oC

Classes of technical plates:

technical plate with a thickness of 1.0 to 20.0 mm, intended for the manufacture of rubber products used to seal units operating under pressure above 0.1 MPa;

technical plate with a thickness of 1.0 to 60.0 mm, intended for the manufacture of rubber products used to seal units operating under pressure above 0.1 MPa, to prevent friction between metal surfaces, as well as to absorb single shock loads or as linings , decking;

Types of technical plates:

Form plate - is made by molding. Molded plates are made in molds with dimensions of 500*500 mm, 600*600 mm;

Rolled plates (unshaped). Roll plate is made by continuous vulcanization, thickness 1-16 mm, length 500-10000 mm, width from 300 to 1200 mm.

Types of technical plates:

I type - rubber plate

Type II - rubber-fabric plate with one or more fabric layers.

Degrees of hardness:

M - soft (TMKShch, AMS - 35-50 Shore A units; MBS - 40-55 Shore A units)

C - medium (TMKShch, AMS - 50-65 units of Shore A; MBS - 55-70 units of Shore A)

T - hard (TMKShch, AMS - 65-85 Shore A units; MBS - 70-90 Shore A units)

Types of plates:

Molded - made by molding (in special molds) on vulcanizing presses with dimensions from 500 x 500 mm,

Unshaped (rolled) - is made by continuous vulcanization (in boilers) by extrusion through dies, thickness 1 - 16 mm, length 500 - 10000 mm, width from 300 to 1200 mm.

Insert classes:

I - plate with a thickness of 1.0 to 20.0 mm, intended for the manufacture of rubber products used to seal units operating under pressure above 0.1 MPa;

II - a plate with a thickness of 1.0 to 60.0 mm, intended for the manufacture of rubber products used to seal units operating under pressure over 0.1

MPa, to prevent friction between metal surfaces, as well as for the perception of single shock loads or as linings, floorings.

Technical plate MBS

MBS technical plates are high-quality products (volcanic rubber sheets), which are intended for the manufacture of modern rubber products. From the technical plates of MBS, the necessary details and shapes are produced (cut or cut down). They are widely used as reliable seals in fixed joints, as gaskets and decks, as well as to ensure reliable operation of equipment under single loads and to prevent friction that can occur between metal surfaces.

The MBS technical plate is able to work efficiently in alkaline and acidic environments, as well as in contact with petroleum products. This type of rubber plate is used in the oil, gas, and fuel industries. For its production, nairit is used - chloroprene rubber.

Types of technical plates:

rubber technical plate (MBS)

rubber-fabric technical plate (with one or several fabric layers) - only plates of the MBS-S, MBS-S1, TMKShch-S, TMKShch-S1 brands The number of fabric layers is determined by agreement between the manufacturer and the consumer, taking into account that for every 2 mm of the plate there should no more than one fabric layer.

Rubber and rubber-fabric technical plates are produced in accordance with the requirements of state standards and the approved reciperam. The main dimensions and parameters (class, type, type, brand, hardness, number of fabric pads and thickness) of technical plates are prescribed in GOST 7338-90. This document also specifies tolerances from the standard and physical and mechanical properties, including tensile strength, elongation at break and compressive deformation, as well as frost resistance coefficients.

Widespread in mechanical engineering as gaskets, seals, insulation received "medium" and "soft":

TMKShch technical plates are heat and frost acid and alkali resistant, resistant to alkaline and acid environments in direct contact, as well as to temperature differences in a given range;

technical plates MBS - oil and petrol resistant, inert to the effects of petroleum products and technical oils;

AMS technical plates are weather and oil resistant, with limited resistance to ozone cracking.

Manufacturers of technical plates must regularly conduct acceptance and periodic tests to verify that the quality of the batch meets the requirements of GOST. Technical plates are black sheets of dense rubber. They are used to make floor coverings in factories. They are used to make electrical insulating mats. They are used to cut out various rubber parts and products that are later used in the automobile and railway industries. These plates are very resistant to temperature changes, aggressive chemical environments, and fuels and lubricants. They are used to cut out borders that are used in gardening to make partitions in gardens and vegetable gardens. The plates make excellent snow scrapers for snow removal machines. They are made in factories in two types. Molded plates, which are created by pressing. They are available in two sizes: five hundred by five hundred millimeters and six hundred by six hundred millimeters. Rolled plates are also called non-molded. They are made by a process of constant vulcanization. They have the following dimensions: thickness from one to sixteen millimeters, length from five hundred to ten thousand millimeters and width from three hundred to one thousand two hundred millimeters. There are two types of technical plates. The first is rubber. The second is rubber with several or one fabric layer. It also has three degrees of hardness, which are written by the first letter on the symbols: soft, medium and hard. They are divided into two classes. Depending on this class, they are used to make parts that operate under different levels of pressure. The first class plates have a thickness of one to twenty millimeters, and the second class - from one to sixty millimeters. Oil and petrol resistant technical plates are used in the gas, oil and fuel industries. They are resistant to alkaline chemicals. The rubber-scan technical plate has several fabric layers for every two millimeters of its thickness to increase its strength, durability and wear resistance. It is made of rubber with added impurities. The sheets are easy to machine, they are cut into pieces of the required size. When working with this product, you should follow safety precautions. Protect your hands with special gloves and your eyes with safety glasses. Buy sheets only from trusted manufacturers who have a license to sell such goods in order to avoid buying fakes. Holes and cracks in rubber are not allowed in production. If these are rubber sheets, they are packed and pulled together in several pieces for storage and further transportation. Rubber has high strength and durability, it will serve you for many years. Rubber is used in various industries: automotive, agriculture, railway and shipbuilding. Various seals, car tires are made of rubber. For everyday use, they are used to make hoses, seals for refrigerators, windows, taps and water pipes. Rubber is used to make insulation in electrical engineering. Rubber sheets are used to cut scrapers for the edges of a snow-clearing machine's bucket. Because of its increased electrical insulation, rubber is used to make protective gloves, boots, and mats for electricians.

No questions about this product, be the first and ask your question.